Complex organic grinding aid for converter heat-stewed steel slag, and preparation and usage methods of grinding aid

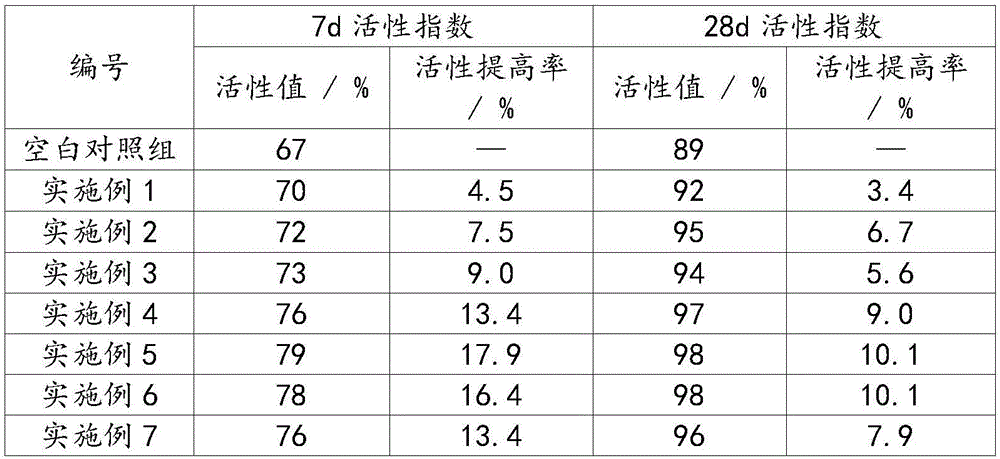

A grinding aid and heat-steaming technology, applied in the field of grinding aids, can solve the problem that cement grinding aids cannot be applied to hot-steamed steel slag in converters, etc., and achieve the effects of excellent comprehensive effect, stable performance and improving the activity of steel slag.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

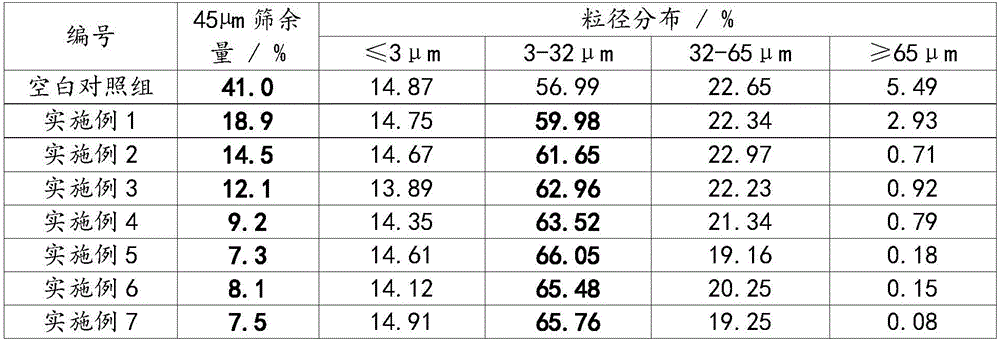

Examples

Embodiment 1

[0025] First get 3 parts of triethanolamine borate and dissolve in 65 parts of water, then add 5 parts of dipropylene glycol, 2 parts of tripropylene glycol, 5 parts of N-methyldiethanolamine successively, mix and stir and then add 20 parts of crude glycerin ( The content of glycerol is 80%, and the by-product of biodiesel is produced), and the compound organic grinding aid is obtained after being stirred evenly.

Embodiment 2

[0027] First get 3.5 parts of triethanolamine borate and dissolve in 59 parts of water, then add 6 parts of dipropylene glycol, 4 parts of tripropylene glycol, 5.5 parts of N-methyldiethanolamine successively, mix and stir and then add 22 parts of crude glycerin ( The content of glycerol is 80%, and the by-product of biodiesel is produced), and the compound organic grinding aid is obtained after being stirred evenly.

Embodiment 3

[0029] First get 4 parts of triethanolamine borate and dissolve in 54 parts of water, then add 7 parts of dipropylene glycol, 3 parts of tripropylene glycol, 6 parts of N-methyldiethanolamine successively, mix and stir and then add 26 parts of crude glycerin ( The content of glycerin is 80%, and the by-product of oil production) is stirred evenly to obtain the compound organic grinding aid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com