Preparation method of potassium thioacetate

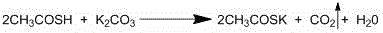

A technology of potassium thioacetate and potassium carbonate, which is applied in the field of preparation of potassium thioacetate, can solve the problems of high production cost, reaction with water, and easy oxidation of air, etc., to reduce production cost, increase yield, and reduce loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

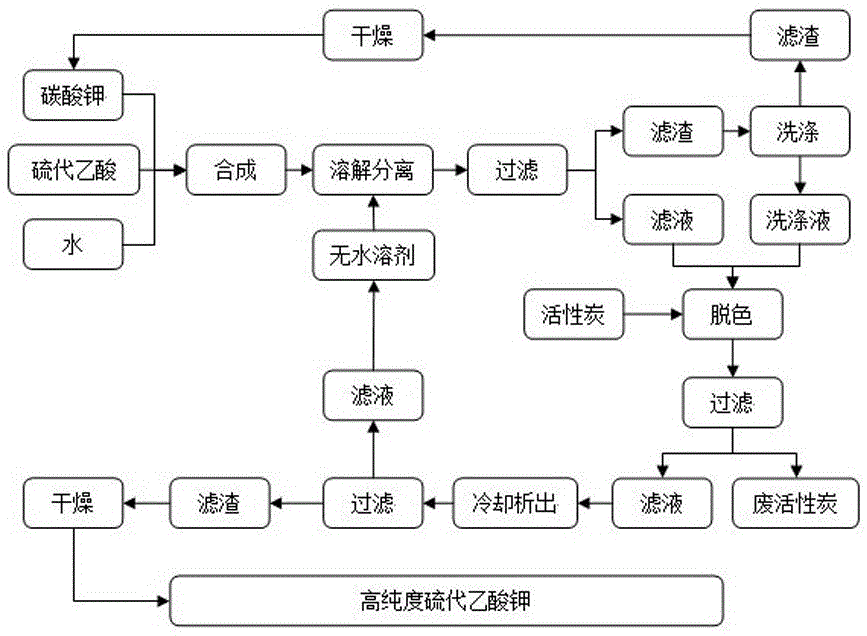

[0041] Please refer to figure 1 , the preparation method of potassium thioacetate in the figure, comprises the steps:

[0042] a, forming potassium thioacetate synthetic material:

[0043] In a 500L conical ribbon vacuum dryer, add 190kg of potassium carbonate or potassium bicarbonate, start the ribbon stirring, add 200kg of thioacetic acid, after stirring evenly, add 10kg of water by spraying, then turn on the vacuum, the vacuum degree -0.01MPa, heat up to 40°C, heat up for 20 minutes, after the temperature reaches 40°C, keep warm for 2 hours, ready for use;

[0044] b. Dissolution and separation:

[0045] In a 1000L reaction pot, add 200L of anhydrous solvent, start stirring, put in the above synthetic material, stir for half an hour, and filter after potassium thioacetate is fully dissolved; the filter residue is washed with anhydrous solvent, due to potassium carbonate and bicarbonate Potassium is almost insoluble in this anhydrous solvent, so the filter residue is pota...

Embodiment 2

[0055] Please refer to figure 1 , the preparation method of potassium thioacetate in the figure, comprises the steps:

[0056] a, forming potassium thioacetate synthetic material:

[0057] In a 500L conical ribbon vacuum dryer, add 240kg of potassium carbonate or potassium bicarbonate, start the ribbon stirring, add 200kg of thioacetic acid, after stirring evenly, add 20kg of water by spraying, then turn on the vacuum, the vacuum degree 0.09MPa, heat up to 80°C, heat up for 30 minutes, after the temperature reaches 80°C, keep warm for 5 hours, ready for use;

[0058] b. Dissolution and separation:

[0059] In a 1000L reaction pot, add 800L of anhydrous solvent, start stirring, put in the above synthetic material, stir for half an hour, and filter after potassium thioacetate is fully dissolved; the filter residue is washed with anhydrous solvent, due to potassium carbonate and bicarbonate Potassium is almost insoluble in this anhydrous solvent, so the filter residue is potassi...

Embodiment 3

[0069] Please refer to figure 1 , the preparation method of potassium thioacetate in the figure, comprises the steps:

[0070] a, forming potassium thioacetate synthetic material:

[0071] In a 500L conical ribbon vacuum dryer, add 220kg of potassium carbonate or potassium bicarbonate, start ribbon stirring, add 200kg of thioacetic acid, after stirring evenly, add 15kg of water by spraying, then turn on the vacuum, the vacuum degree -0.06MPa, heat up to 60°C, heat up for 25 minutes, after the temperature reaches 60°C, keep warm for 3 hours, ready for use;

[0072] b. Dissolution and separation:

[0073] In a 1000L reaction pot, add 600L of anhydrous solvent, start stirring, put in the above synthetic material, stir for half an hour, and filter after potassium thioacetate is fully dissolved; the filter residue is washed with anhydrous solvent, due to potassium carbonate and bicarbonate Potassium is almost insoluble in this anhydrous solvent, so the filter residue is potassiu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com