High-flexibility water varnish suitable for UV (Ultraviolet) curable offset printing and preparation method of water varnish

A flexible and water-based technology, applied in the field of high-flexibility water-based varnish and its preparation, it can solve the problems of scrapped printed matter, restricted application of water-based varnish, and UV ink bursting, etc., and achieves good adhesion, excellent interlayer adhesion, and low VOC. The effect of emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with specific embodiment:

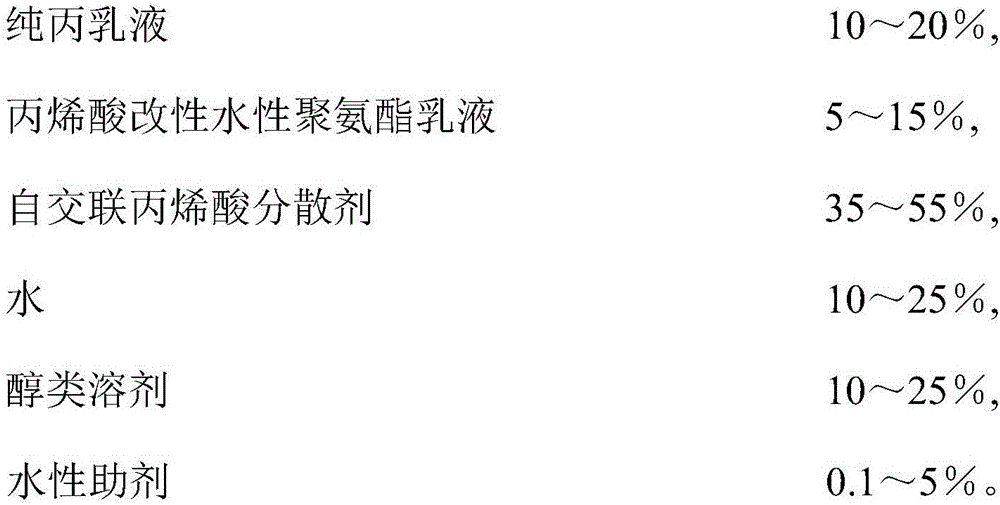

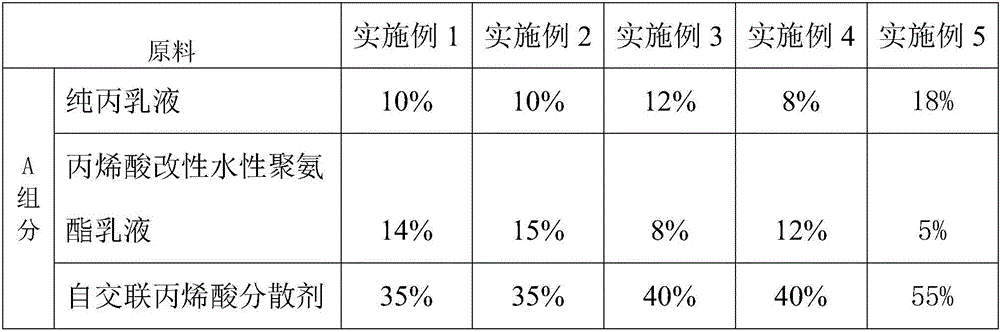

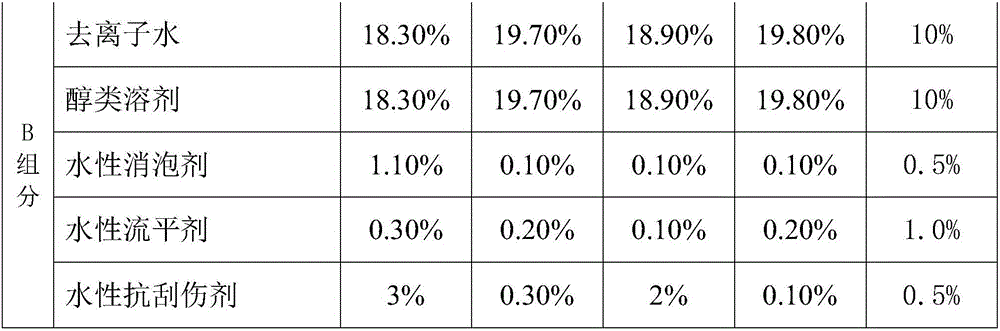

[0034] Each component of embodiment 1~5 is composed as shown in table 1 by weight percentage:

[0035] Table 1:

[0036]

[0037]

[0038] The preparation method of the highly flexible water-based varnish of embodiment 1~5:

[0039] 1) Configure component A: Add pure acrylic emulsion, acrylic modified water-based polyurethane emulsion, and self-crosslinking acrylic dispersant to the dispersion tank according to the formula ratio, and stir at 200 rpm for 15 minutes.

[0040] 2) Configure component B: add deionized water, alcohol solvent, and water-based additives into the mixing tank according to the proportion, and stir at 300 rpm for 15 minutes.

[0041] 3) Mixing: Pump the uniformly stirred component B into the dispersion tank, mix with component A, and stir at 200 rpm for 15 minutes.

[0042] 4) Filtration and purification packaging: remove impurities through fil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| minimum film forming temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com