Manufacturing method for reinforced cutting tooth

A pick and cermet technology, applied in the field of mechanical processing, can solve the problems of reducing production efficiency and increasing mining costs, and achieve the effects of improving production efficiency, reducing replacement and maintenance time, and improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

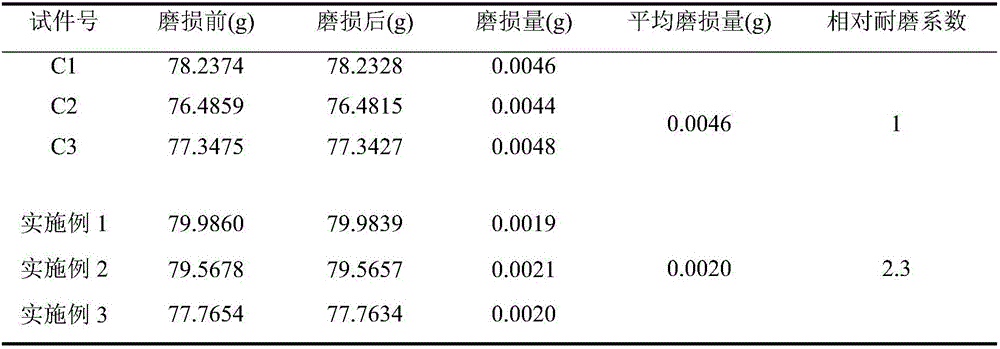

Embodiment 1

[0018] (1) Degrease the surface of the pick and clean it with alcohol;

[0019] (2) prepare cermet alloy powder, the mass percent of each component of cermet alloy powder is: nickel clad diamond 4%, Cr 13%, Si 2%, Mo 3%, balance is Fe, and powder particle size is 100~320 orders ;

[0020] (3) Put the prepared cermet alloy powder into a mechanical three-dimensional powder mixer and mix thoroughly, and the mixing time is 3 hours;

[0021] (4) Fix the pick on the positioner, and carry out laser cladding on the high-power semiconductor laser processing tooling platform. The cladding process adopts gravity preset powder feeding, and the thickness of the cermet alloy powder is 1.5mm; use high-power semiconductor The high-energy beam output by the laser scans and transports the cermet alloy powder in step (3) in place, so that the cermet alloy powder and the surface metal of the pick have a rapid metallurgical reaction to obtain a uniform wear-resistant and anti-corrosion ceramic al...

Embodiment 2

[0026] (1) Degrease the surface of the pick and clean it with alcohol;

[0027] (2) prepare cermet alloy powder, the mass percentage of each component of cermet alloy powder is: nickel-coated diamond 6%, Cr 13%, Si 2.5%, Mo 3%, the balance is Fe, and the powder particle size is 100~320 orders ;

[0028] (3) Put the prepared cermet alloy powder into a mechanical three-dimensional powder mixer and mix thoroughly, and the mixing time is 3 hours;

[0029] (4) Fix the pick on the positioner, and carry out laser cladding on the high-power semiconductor laser processing tooling platform. The cladding process adopts gravity preset powder feeding, and the thickness of the cermet alloy powder is 2mm; use a high-power semiconductor laser The output high-energy beam scans the metal-ceramic alloy powder delivered in step (3), so that the metal-ceramic alloy powder and the pick surface metal undergo a rapid metallurgical reaction to obtain a uniform wear-resistant and corrosion-resistant c...

Embodiment 3

[0033] (1) Degrease the surface of the pick and clean it with alcohol;

[0034] (2) prepare cermet alloy powder, the mass percent of each component of cermet alloy powder is: nickel-coated diamond 5%, Cr 14%, Si 3.5%, Mo 5%, the balance is Fe, and the powder particle size is 100~320 orders ;

[0035] (3) Put the prepared cermet alloy powder into a mechanical three-dimensional powder mixer and mix thoroughly, and the mixing time is 3 hours;

[0036] (4) Fix the pick on the positioner, and carry out laser cladding on the high-power semiconductor laser processing tooling platform. The cladding process adopts gravity preset powder feeding, and the thickness of the cermet alloy powder is 1.6mm; use high-power semiconductor The high-energy beam output by the laser scans and transports the cermet alloy powder in step (3) in place, so that the cermet alloy powder and the surface metal of the pick have a rapid metallurgical reaction to obtain a uniform wear-resistant and anti-corrosio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com