Fabricated operation platform for tensioning deep foundation pit anchor cable

An operating platform and deep foundation pit technology, applied in infrastructure engineering, construction, excavation, etc., can solve the problems of time-consuming and labor-intensive, poor safety and stability, and high construction cost, and achieve convenient material selection, convenient installation, and low processing costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

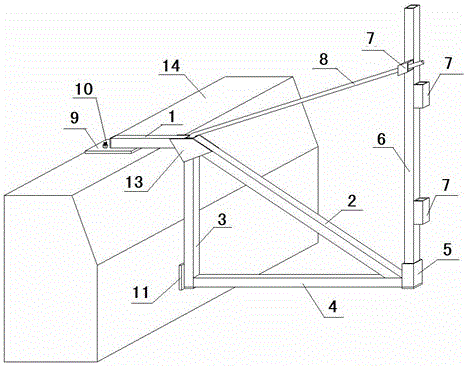

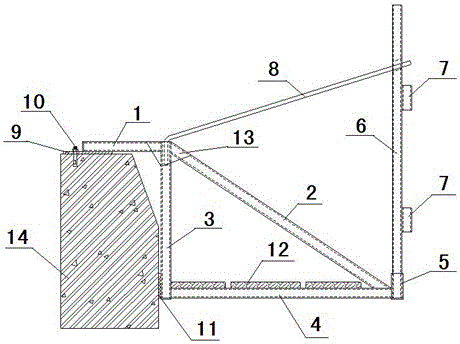

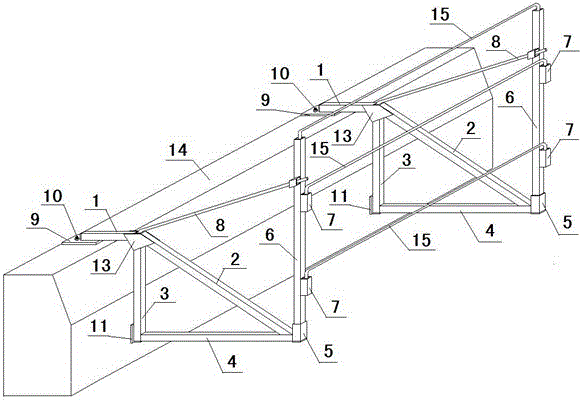

[0029] refer to Figure 1-Figure 4 , this embodiment includes support steel connecting rod 1, diagonal stay rod 2, steel vertical rod 3, platform rod 4, railing column insertion tube 5, railing column 6, railing handrail rod insertion tube 7, longitudinal handrail rod 8 and support steel plate 9. The diagonal tie rod 2, the steel vertical rod 3 and the platform rod 4 are connected to form a triangle, which is the main force-bearing member of the overhanging part of the entire operation platform, and the reinforced steel plate 13 is connected to the support steel connecting rod 1 through the member nodes The support steel connecting rod 1 is connected to the support steel plate 9 through fillet welds, the support steel plate 9 is connected to the deep foundation pit anchor cable crown beam or waist beam 14 through embedded bolts 10, and the railing column is inserted The pipe 5 is fixed on the end of the platform pole 4, and the railing column 6 is axially inserted and fixed in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com