Sand-free precipitation well and construction method thereof

A construction method and technology of dewatering wells, applied in infrastructure engineering, construction, etc., can solve problems such as slow construction speed, large hole diameter, and large sand consumption, and achieve fast construction speed, reliable quality, and good environmental protection benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

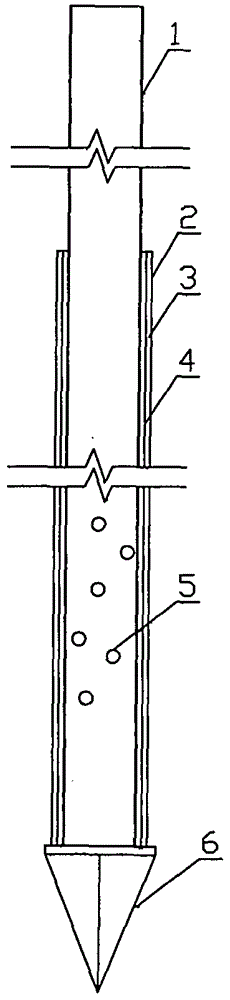

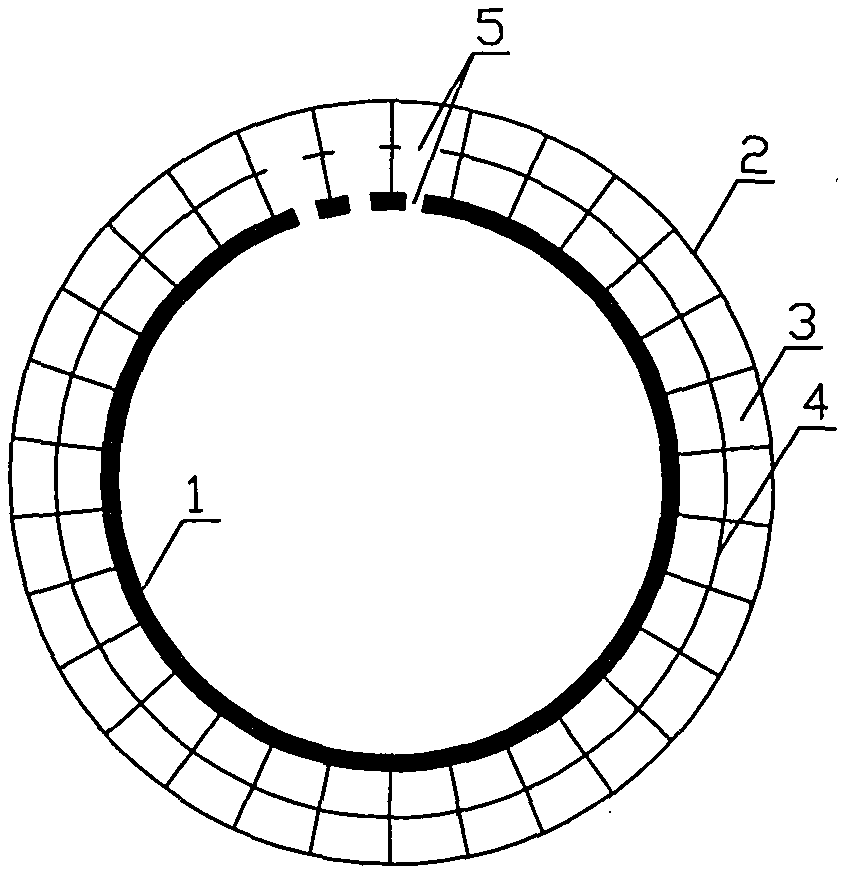

[0019] As an embodiment of the present invention, mainly in combination with figure 1 and figure 2 The structure, working principle and construction method of the sand-free dewatering well of the present invention are introduced. The sand-free dewatering well of the present invention includes four parts, the well pipe (1), the water filter membrane (2), the water collection tank (3), and the water outlet channel (5), wherein the well pipe (1) is a temporary storage space for groundwater or groundwater The tubular structure providing the space is extracted. The well pipe (1) can be made of a steel pipe, and the size and wall thickness of the steel pipe can be customized according to the requirements of the pumping equipment. As deep well dewatering, considering that the water pump will be placed in the well pipe (1), the steel pipe with larger diameter can be used, and the diameter of the steel pipe generally selected can be 100~300mm. If the vacuum well point is used to de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com