Sea sand concrete column provided with fiber cloth instead of stirrup

A technology of concrete columns and fiber cloth, which is applied in the direction of columns, pier columns, pillars, etc., can solve problems such as corrosion of steel skeletons, and achieve the effects of convenient construction, good durability, and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

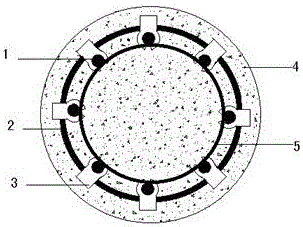

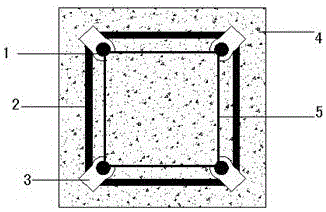

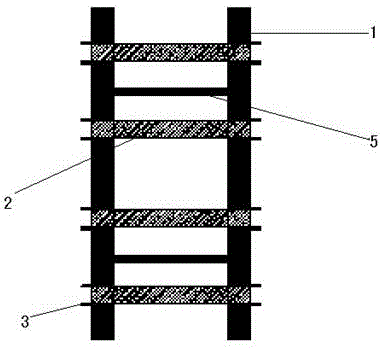

[0040] According to the embodiment of the present invention, a new type of fiber cloth is provided to replace the stirrups to form a sea-sand concrete column in which the inner skeleton of the column is formed, such as figure 1 , 2 As shown, including: 1. Fiber reinforcement, 2. Fiber cloth, 3. Card slot, 4. Sea sand concrete, 5. Stainless steel bracket.

[0041] When making the inner frame of the column, the number, size and spacing of the fiber reinforcement should be selected according to the actual engineering requirements, and the size of the stainless steel bracket should be selected according to the spacing of the longitudinal reinforcement, and it should be welded at equal intervals inside the longitudinal reinforcement skeleton. The stirrup spacing required by the actual project is fastened to the corresponding position of the fiber reinforcement. In order to prevent the fiber cloth from moving up and down along the longitudinal bars, the contact parts of the fiber c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com