Tubing plunger

A plunger and oil pipe technology, applied in the field of oil extraction equipment, can solve the problems of increasing sliding friction, sliding friction and wear of the inner wall of the plunger oil pipe, etc., so as to increase the sliding friction, reduce the risk of oil leakage and water leakage, and improve the service life long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

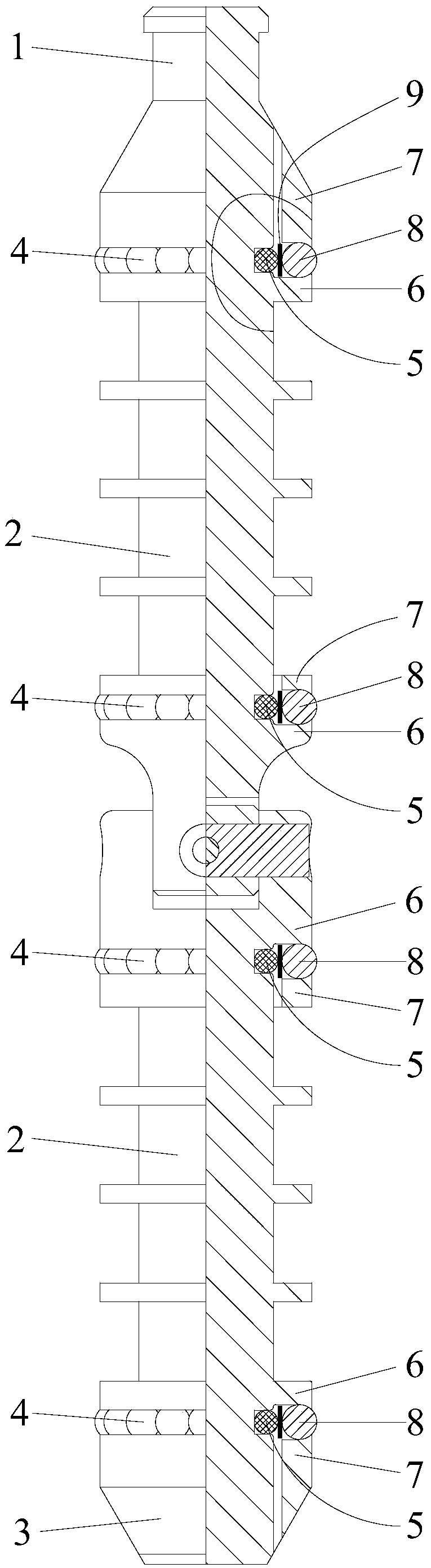

[0027] like Figure 1-2 As shown, a tubing plunger according to the present invention includes a fishing head 1 , a guiding head 3 and at least one plunger section 2 .

[0028] The ends of two adjacent plunger segments 2 are hinged to form a plunger segment string, the fishing head 1 is connected to one end of the plunger segment string, and the guide head 3 is connected to the end of the plunger segment string. At the other end, at least one roller collar 4 is sleeved on the outer wall of each of the plunger sections 2, and the outer diameters of all the roller collars 4 are larger than the maximum diameter of the fishing head 1, the guide head 3 The maximum diameter and the maximum outer diameter of each of the plunger section 2 body.

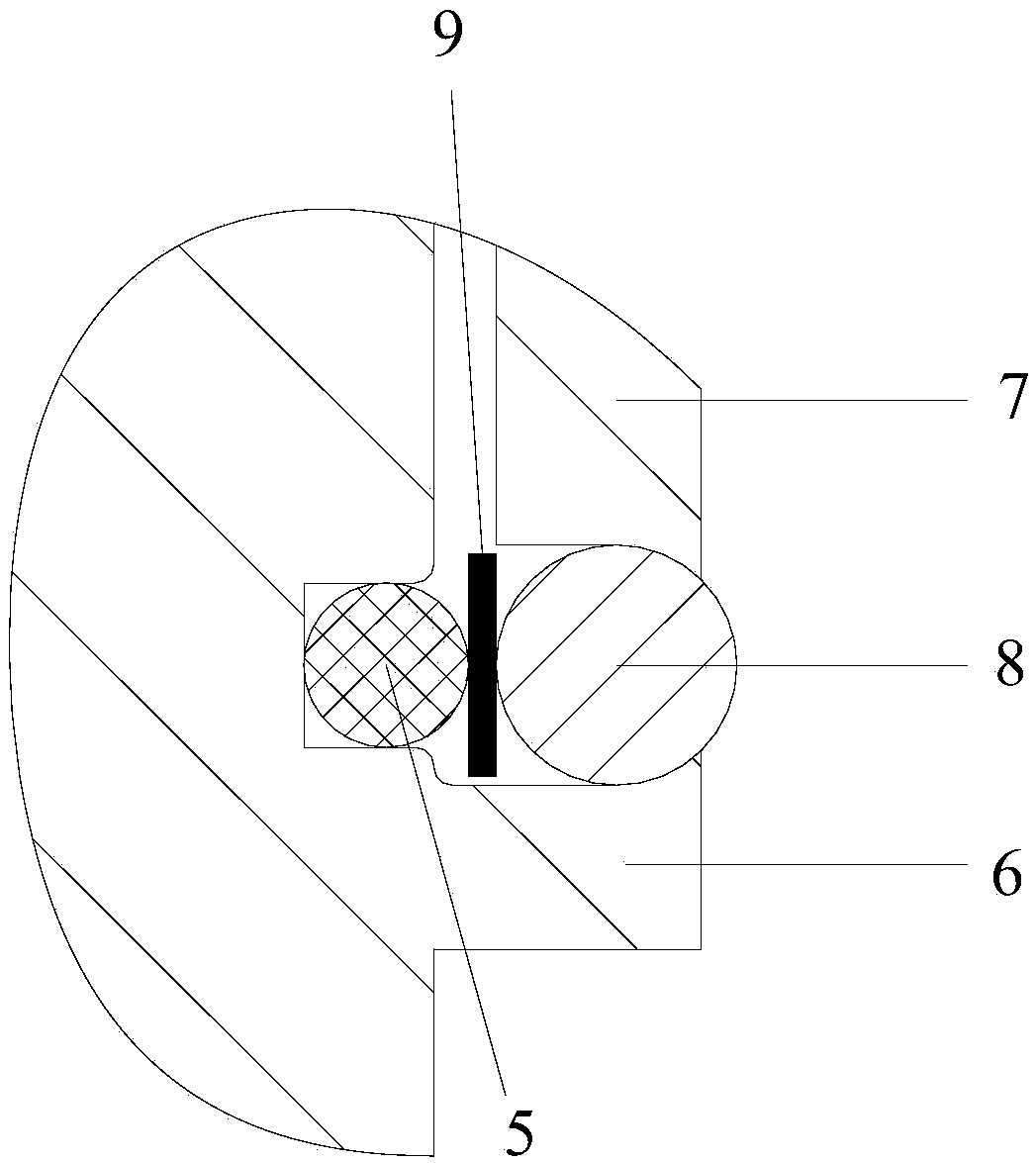

[0029] As a preferred solution of this embodiment, each of the roller collars 4 is provided with an elastic member 5 inside, and all the elastic members 5 are connected to each of the corresponding plunger segments 2. With this structure, ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com