A continuous automatic water discharge and slag discharge device for gas drainage pipeline

A gas extraction and pipeline technology, which is applied in the field of continuous automatic water and slag discharge devices for gas extraction pipelines, can solve the problems of inability to synchronize the extraction process intermittently and discontinuously, the inability of automatic cleaning of equipment and devices, and the blockage of the extraction pipes. , to facilitate the difficulty of cleaning equipment, save labor and material costs, and improve the effect of gas moisture content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with examples, but the embodiments of the present invention are not limited thereto.

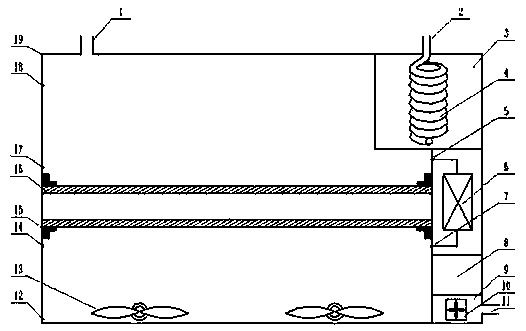

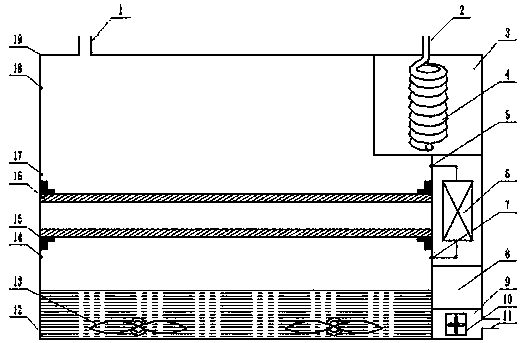

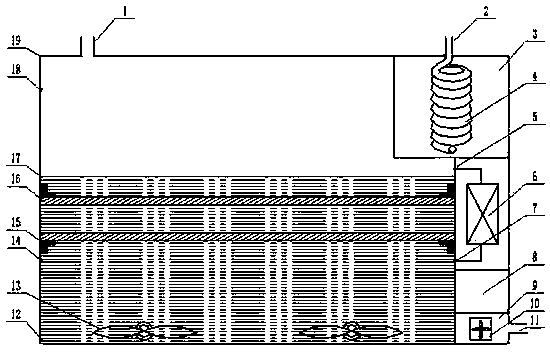

[0021] like Figure 1-6 As shown, a continuous automatic water discharge and slag discharge device for gas drainage pipeline consists of a main box body 19 of the device, a water tank body 21 of the device, a gas drainage inlet 1, a gas negative pressure drainage port 2, a condensation system 3, It is composed of pressure regulating system 6, control system 8, water discharge and slag discharge system 9, water level monitoring system, water slag mixer 13, pressure monitoring system, sealing plate guide groove 15, and sealing plate 16.

[0022] The two sides of the top of the main box body 19 of the device are respectively provided with a gas extraction air inlet 1 and a gas negative pressure extraction port 2, and a water tank body 21 is arranged in the main box body 19 of the device, and the gas extraction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com