Middle-sized low-speed permanent magnetic direct drive wind turbine generator and parameter self-study control method thereof

A technology of permanent magnet direct drive and wind turbine, which is applied in the direction of wind motor combination, wind engine control, engine control, etc. It can solve the problems of not being able to meet the cost control requirements, increasing the production cost of generators, and requiring high motor protection performance. , to achieve the effect of good heat dissipation, reduction of load-bearing parts, and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

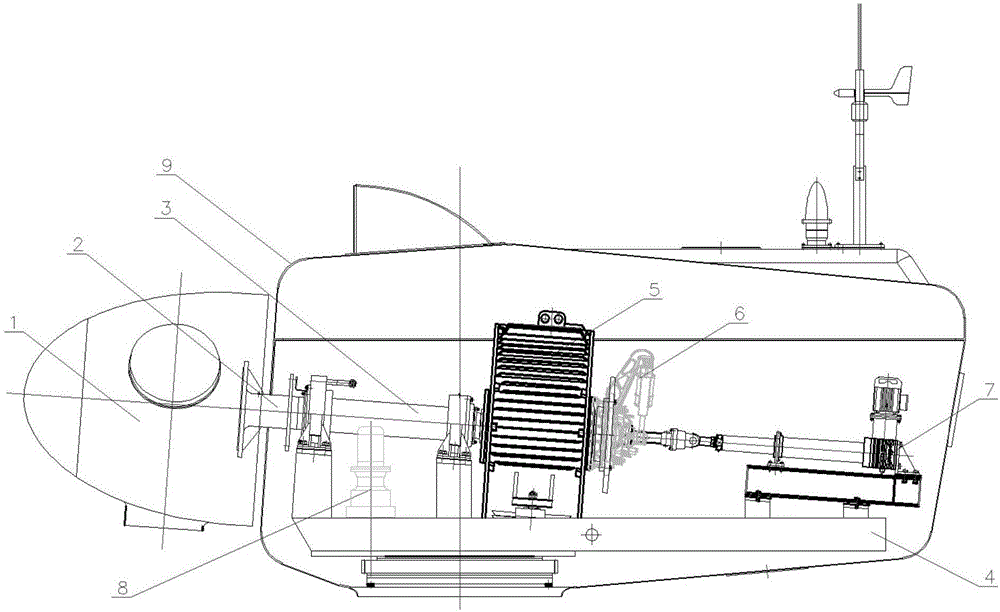

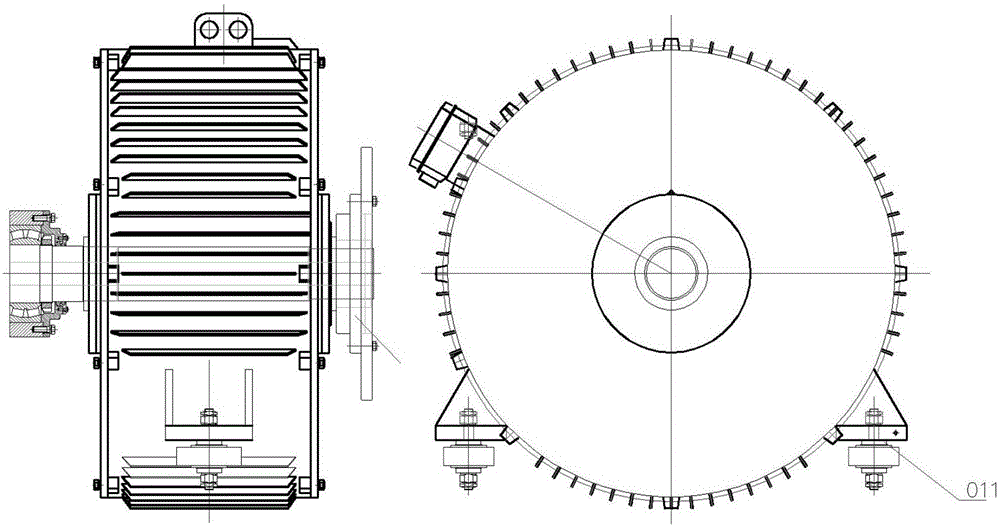

[0028] Such as figure 1 The wind power generating set includes a wind wheel (1), a main shaft (2), a main bearing housing (3), a main frame (4), a low-speed disc permanent magnet motor (5), a low-speed shaft brake (6), and a variable pitch drag Drive system (7), yaw drag system (8), nacelle cover (9).

[0029] The wind wheel (1) is connected to the front end of the main shaft (2) with high-strength bolts; the main shaft (2) is connected to the bearing seat (3) through the bearing in the bearing seat (3); the wind wheel (1) is driven by the wind, and the The torque load of (2) directly acts on the rotor of the generator (5) for power generation, and other various loads are all transmitted to the main frame (4) by the bearing seat (3).

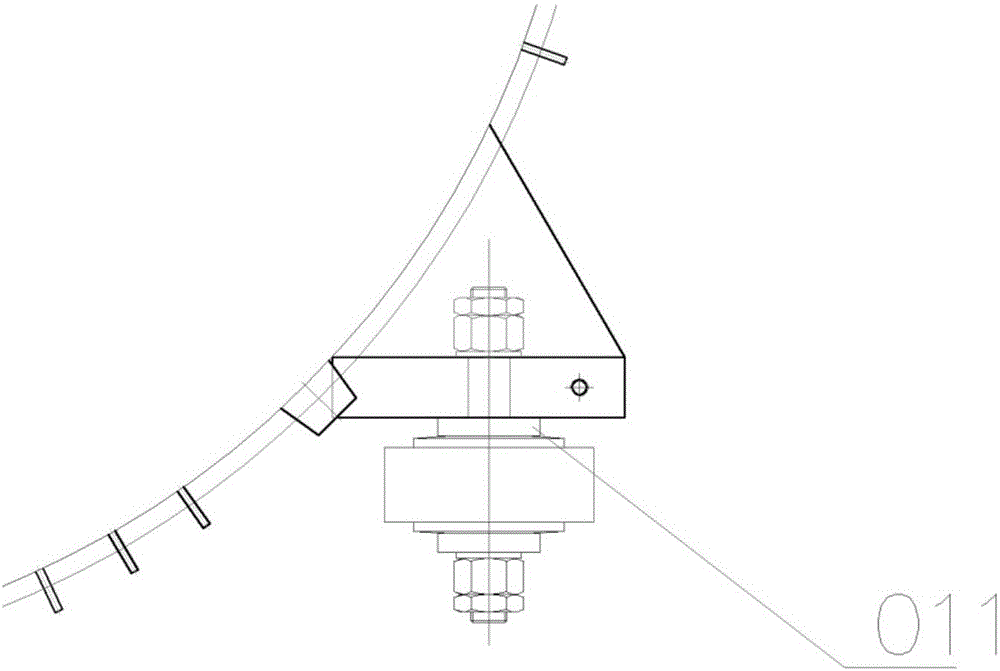

[0030] The shaft of the permanent magnet generator (5) is hollow, and is sleeved on the outside of the main shaft (2), the generator rotor and the main shaft (2) can rotate synchronously, and the gravity of the generator is borne by the main sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com