A Parametric Design Method for Multiphase Permanent Magnet Motor

A technology of parametric design and permanent magnet motor, applied in the direction of design optimization/simulation, special data processing application, etc., can solve the problem that it is difficult to meet the requirements of precision, efficiency and versatility of permanent magnet motor, and does not meet the rapidity of permanent magnet motor Requirements and other issues to achieve the effect of improving design efficiency, avoiding modeling errors, and improving design level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

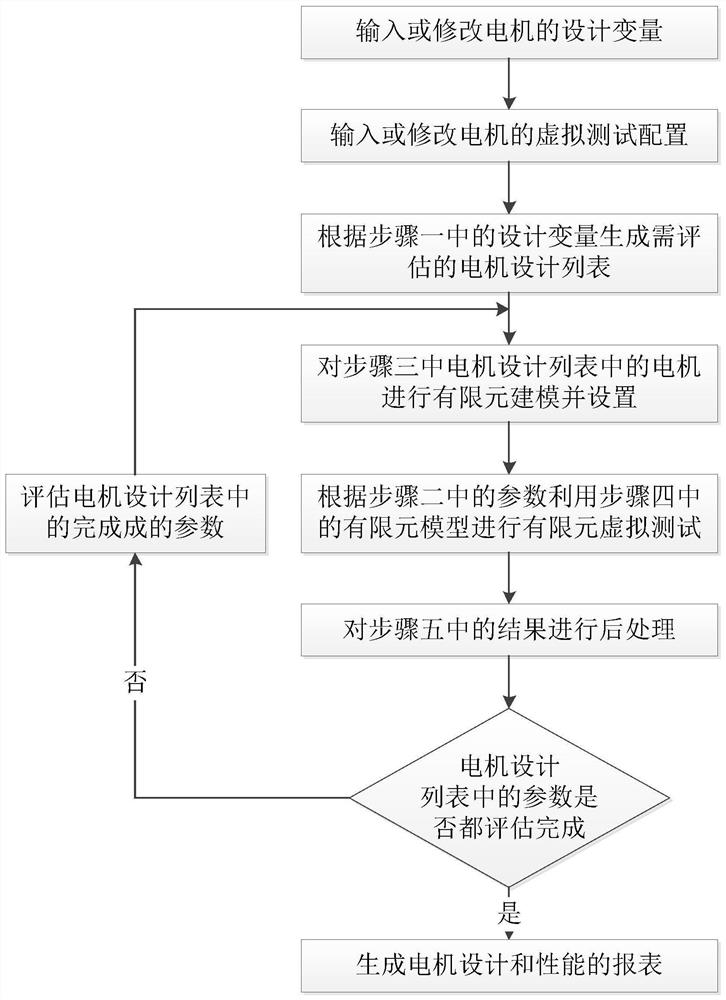

[0049] pass below Figure 1 ~ Figure 2 And the way of enumerating some optional embodiments of the present invention, the technical solution of the present invention (including the preferred technical solution) is described in further detail, and any technical feature and any technical solution in this embodiment do not limit the protection scope of the present invention .

[0050] Such as figure 1 Shown, the parametric design method of the polyphase permanent magnet motor that the present invention designs is characterized in that comprising the following steps:

[0051] 1. Input or modify the design variables of the motor;

[0052] The design variables include setting variables, general design variables, unique design variables of different groove types and unique design variables of different rotor pole types; preferably, the input value of any of the design variables can be a single value, It can also be an array, indicating the traversal value range of the motor design...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com