Variable structure control method for vehicle-mounted compound power distribution slide film

A technology of variable structure control and compound power supply, applied in the parallel operation of DC power supply and other directions, can solve the problems of fixed control rules, inability to adapt to changes in electric vehicle operating conditions, and inability to adjust online in time, to meet dual needs, High stability and energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

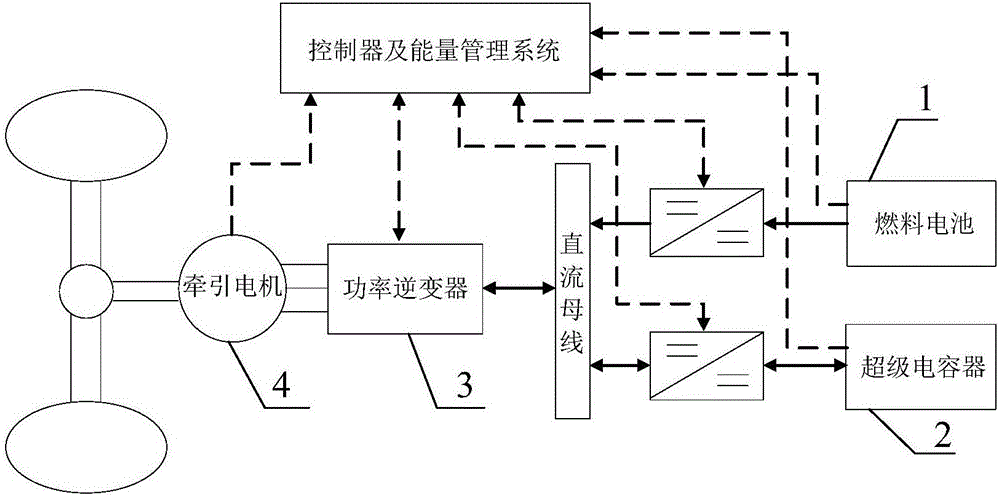

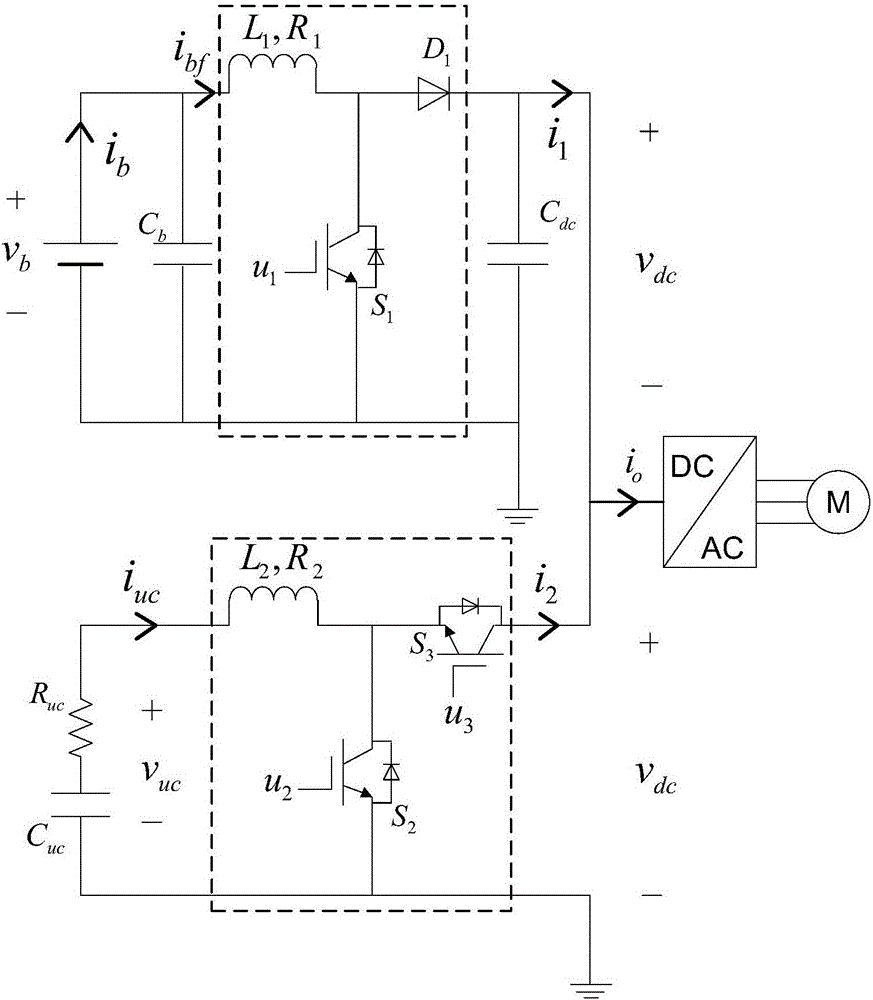

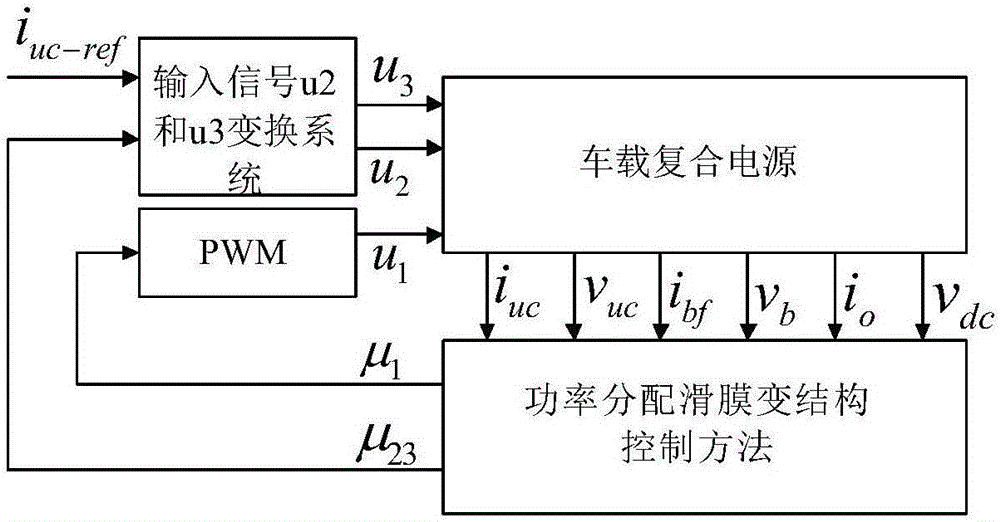

[0029] Such as Figure 1-4 As shown, the invention discloses a synovial film variable structure control method for power distribution of a vehicle-mounted composite power supply. figure 1 The on-board power supply in the system performs power distribution control. Among them, the non-reversible Boost converter adopts the classic DC bus voltage feedback closed-loop control, and the reversible Buck-Boost converter adopts the supercapacitor 2 current tracking control, that is, the actual value of the current i uc Keep track of its reference value i uc-ref , i uc-ref It is a value that changes from time to time according to actual working conditions.

[0030] (1) Energy model

[0031] The fuel cell 1 is equivalent to a DC voltage source v in the modeling process b, the output current is i b ,Such as figure 2 shown. The supercapacitor 2 is equivalent to an ideal capacitor C uc Its equivalent series resistance R during charging and discharging uc In a series structure, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com