Novel multi-port electric energy conversion and switching system

A technology for electric energy conversion and switching systems, which is applied in the energy industry, a single AC network with different frequencies, and an AC network with the same frequency from different sources, etc. It can solve the problems of reducing motor life, system flexibility constraints, and greater impact. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

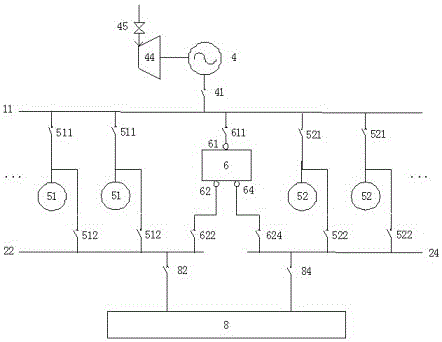

specific Embodiment approach 1

[0132] Such as figure 1 Shown, the concrete embodiment of a kind of novel multi-port electric energy conversion and switching system of the present invention, it comprises No. 11 factory busbar 11, No. 22 factory busbar 22, No. 24 factory busbar 24, variable frequency generator 4, A small steam turbine 44 that drives the variable frequency generator 4 to generate alternating current with a variable frequency, a steam inlet regulating valve 45 that controls the steam inlet volume of the small steam turbine 44, a power frequency plant power system 8, and multiple No. 51 factory auxiliary motors 51 , multiple electric motors 52 of No. 52 plant auxiliary machines, and can adjust the frequency and / or voltage of at least one connection end, and control electric energy to flow between plant buses of different frequencies, or, can control electric energy at different frequencies and A power converter 6 capable of controlling the flow of electric energy between plant buses of the same...

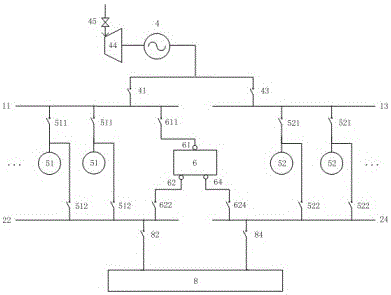

specific Embodiment approach 2

[0188] Such as figure 2 Shown, the specific embodiment of a kind of novel multi-port power conversion and switching system of the present invention, it comprises No. 11 factory busbar 11, No. 13 factory busbar 13, No. 22 factory busbar 22, No. 24 factory busbar 24. Variable frequency generator 4, small steam turbine 44 that drives variable frequency generator 4 to generate alternating current with variable frequency, steam inlet regulating valve 45 that controls the amount of steam inlet of small steam turbine 44, power frequency plant power system 8, multiple units No. 51 The electric motor 51 of the factory auxiliary machine, the motor 52 of multiple No. 52 factory auxiliary machines, and the frequency and / or voltage of at least one connection end can be adjusted, and the electric energy can be controlled to flow between the factory busbars of different frequencies, or both A power converter 6 that can control electric energy at different frequencies and can control electri...

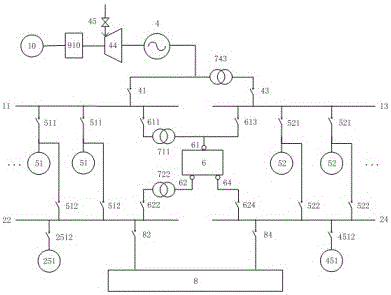

specific Embodiment approach 3

[0244] Such as image 3 Shown, the specific embodiment of a kind of novel multi-port power conversion and switching system of the present invention, it comprises No. 11 factory busbar 11, No. 13 factory busbar 13, No. 22 factory busbar 22, No. 24 factory busbar 24. Variable frequency generator 4, small steam turbine 44 that drives variable frequency generator 4 to generate alternating current with variable frequency, steam inlet regulating valve 45 that controls the amount of steam inlet of small steam turbine 44, power frequency plant power system 8, multiple units No. 51 The electric motor 51 of the factory auxiliary machine, the motor 52 of multiple No. 52 factory auxiliary machines, and the frequency and / or voltage of at least one connection end can be adjusted, and the electric energy can be controlled to flow between the factory busbars of different frequencies, or both A power converter 6 that can control electric energy at different frequencies and can control electric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com