CPLD-based brushless motor electronic commutation method

An electronic commutation, brushless motor technology, applied in the field of servo system control, can solve the problems of occupying memory, reducing control reliability, and no motor power-on self-checking function, achieving high reliability, preventing bridge arm pass-through, interface simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

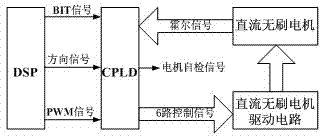

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments. Such as figure 1 As shown, the CPLD obtains the direction signal and PWM signal from the DSP, combines the Hall position signal of the motor, and outputs 6 control signals to the motor drive circuit to drive the motor to rotate.

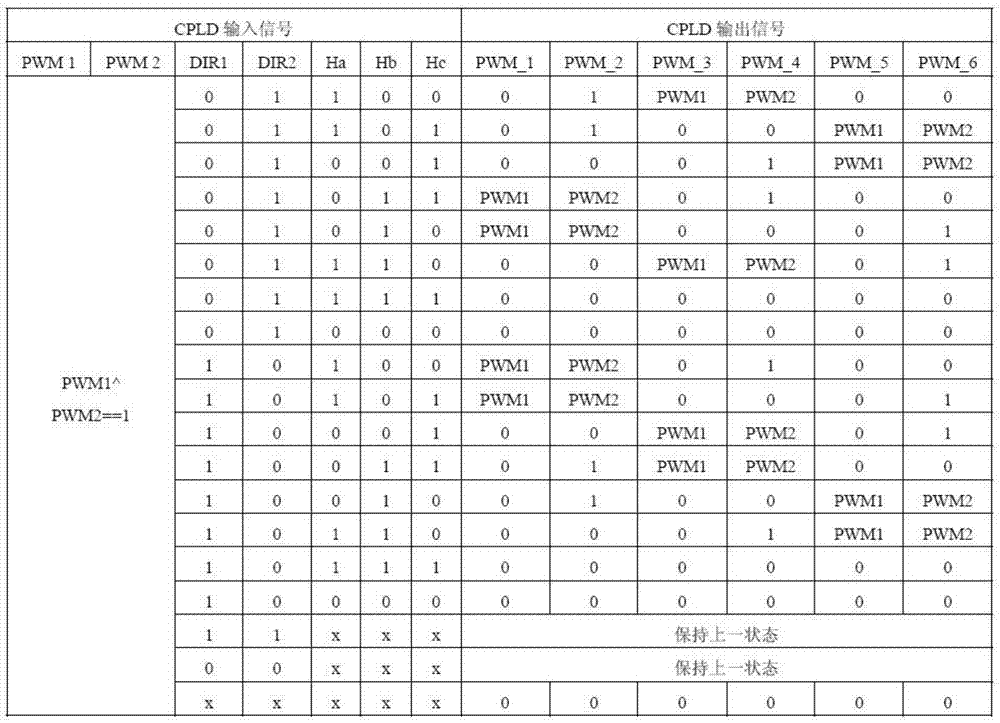

[0015] 1. The input signals of CPLD include: PWM signals PWM1 and PWM2 output by two DSPs; direction signals DIR1 and DIR2 output by two DSPs; three motor Hall position signals Ha, Hb and Hc. The output signals of CPLD include: six-way PWM control signals PWM_1~PWM_6, the logic switching of which is shown in Table 1.

[0016] Table 1 Motor Logic Switching Table

[0017]

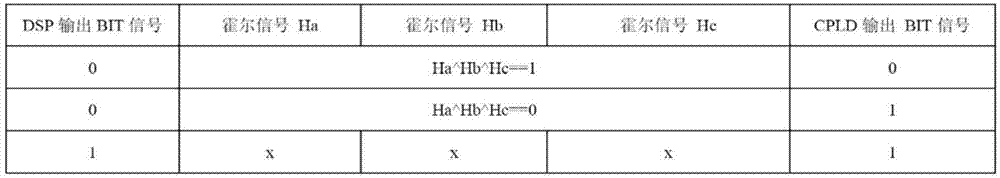

[0018] 2. The CPLD receives the BIT signal output by the DSP and the Hall position signal of the motor, and outputs an effective motor self-test BIT signal in real time. Its logical switching is shown in Table 2.

[0019] Table 2 Motor self-test BIT sign...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com