A tundish working layer lining structure for absorbing inclusions in molten steel

A technology of tundish and working layer, which is applied in the direction of manufacturing tools, metal processing equipment, casting melt containers, etc., can solve the problems of volume expansion, hydrogenation of molten steel, easy hydration, etc., so as to improve service life and prevent water absorption and dehydration , the effect of high reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

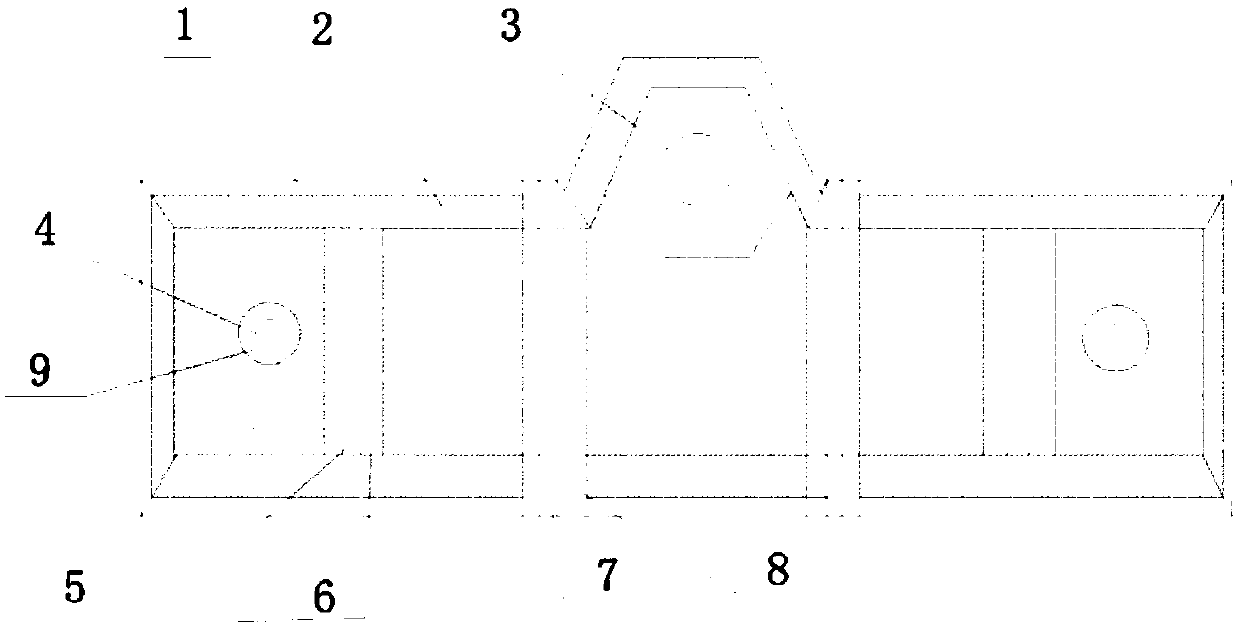

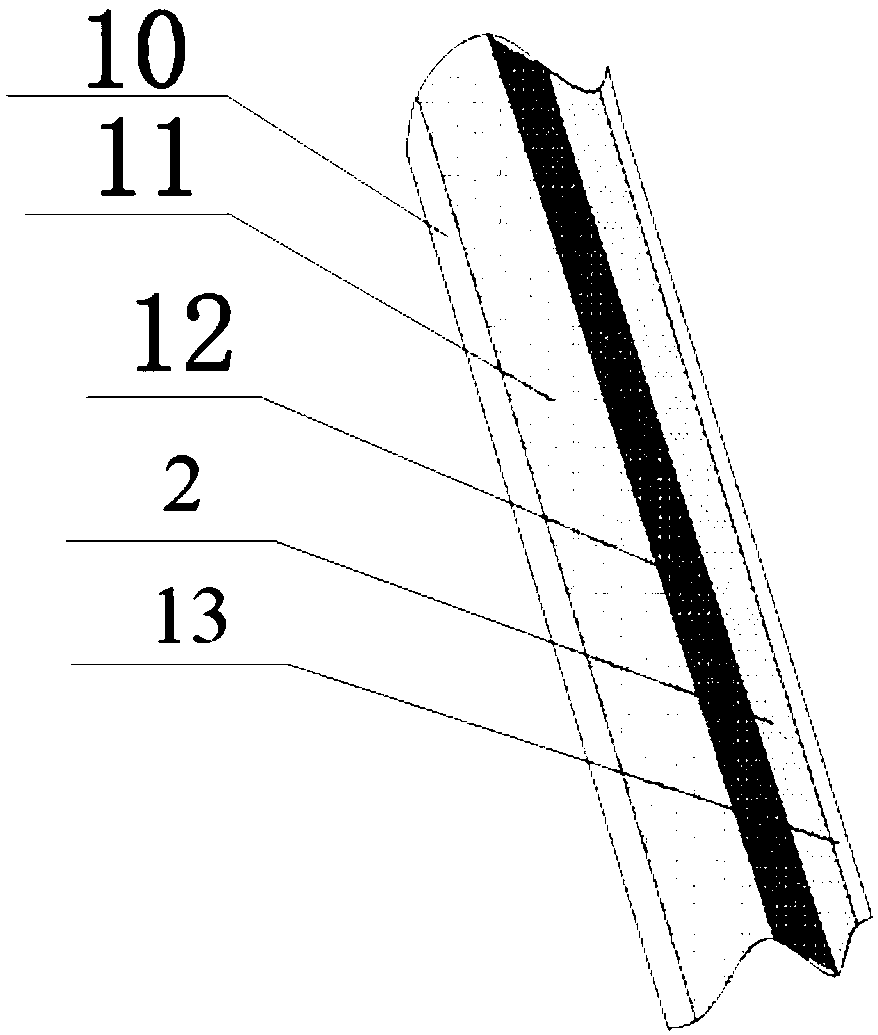

[0036] make one such as figure 1In the tundish shown, a layer of tundish working liner 12 with a thickness of about 22 mm is poured on the permanent layer 11 of the tundish with MgO dry material, molded by tire membrane vibration, and baked at a temperature of 200°C 4 hours, take off the membrane and set aside.

[0037] Within the area of 100mm outside the installation position of the nozzle 4, retaining wall 7 and retaining dam 5 of the tundish, use MgO dry material on the working lining layer of the tundish to form a 20mm thick working lining surface layer (corresponding to For the working lining surface layer 9 of the nozzle, the working lining surface layer 8 of the retaining wall and the working lining surface layer 6 of the retaining dam, to facilitate the later installation of the nozzle, retaining wall and retaining dam, the slag line and the bag edge are rammed with MgO dry material A 20mm thick MgO working lining surface layer 1 is formed to achieve the effect of ...

Embodiment 2

[0044] make one such as figure 1 In the tundish shown, a layer of tundish working liner 12 with a thickness of about 25 mm is poured on the permanent layer 11 of the tundish with MgO-based dry castable material, formed by vibrating tire membranes, and baked at a temperature of 400°C Bake for 2 hours, remove the film and set aside.

[0045] Within the area of 150 mm around the installation position of the tundish nozzle 4, retaining wall 7 and retaining dam 5, use MgO dry material to pound into a 15 mm thick working lining surface layer (corresponding to the nozzle working lining surface layer 9 and retaining wall working lining surface layer respectively). The surface layer 8 and the working lining surface layer 6) of the retaining dam are convenient for the post-installation of the nozzle, the retaining wall and the retaining dam. The slag line and the bag edge are pounded into a 15mm thick MgO working lining surface layer 1 with MgO dry material at the position of the slag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com