Cement paste stirring device and method

A mixing device and cement slurry technology, which is applied in the direction of cement mixing device, unloading device, clay preparation device, etc., can solve the problems of waste, inconvenient indoor test, and increase the difficulty of cleaning, so as to prevent agglomeration from settling, easy to operate, Anti-splatter effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the drawings and embodiments.

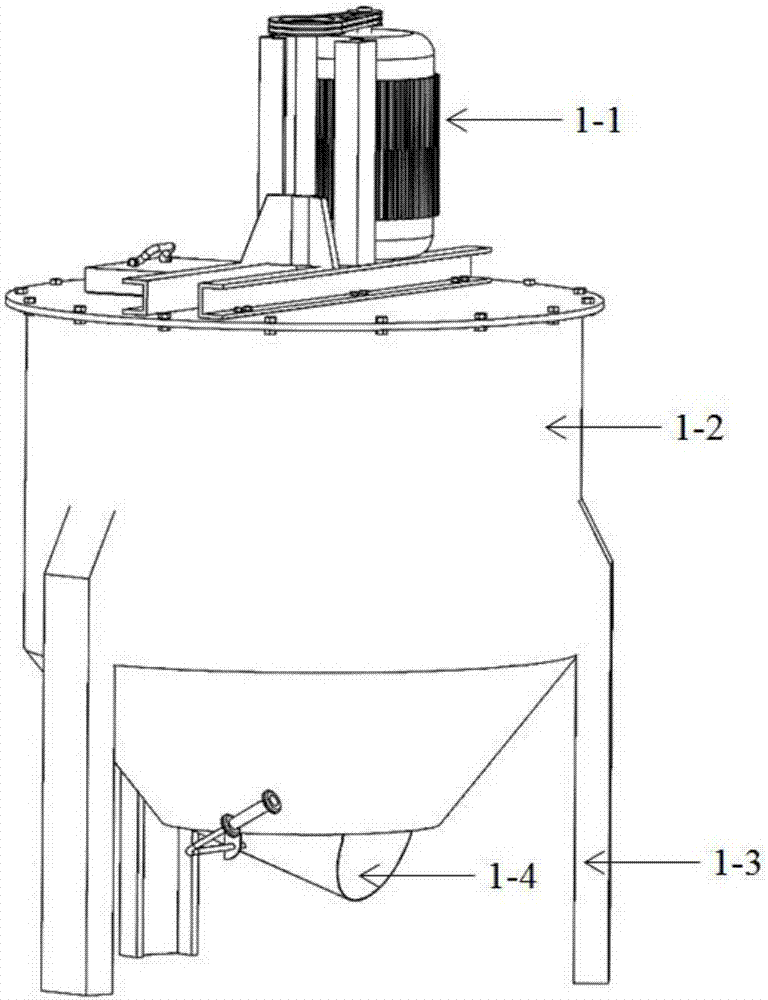

[0028] Such as figure 1 As shown, a cement slurry mixing device includes a power module 1-1, a mixing device, a slurry output device, and a mixer container 1-2.

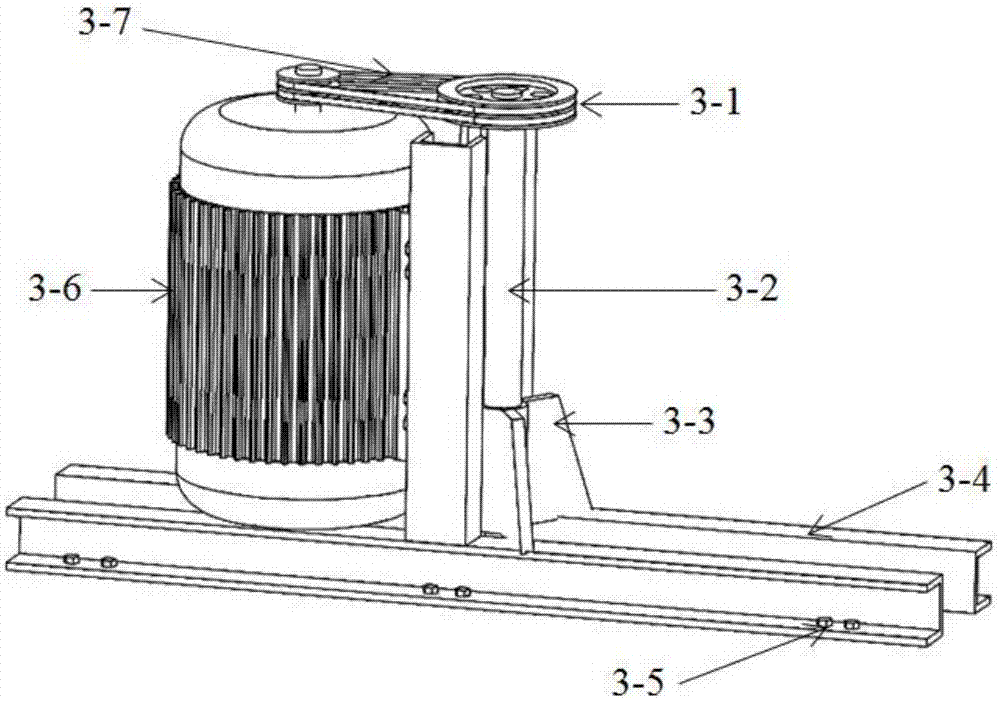

[0029] Such as image 3 As shown, the power module 1-1 includes a motor 3-6, a flywheel 3-1, a belt 3-7, and a fixed support 3-4. The motor of the power module 1-1 is used for stirring through the flywheel 3-1 and the belt 3-7. The device provides power, and all devices of the power module 1-1 are fixed on the upper part of the mixer container 1-2 through bolt bearings and supports.

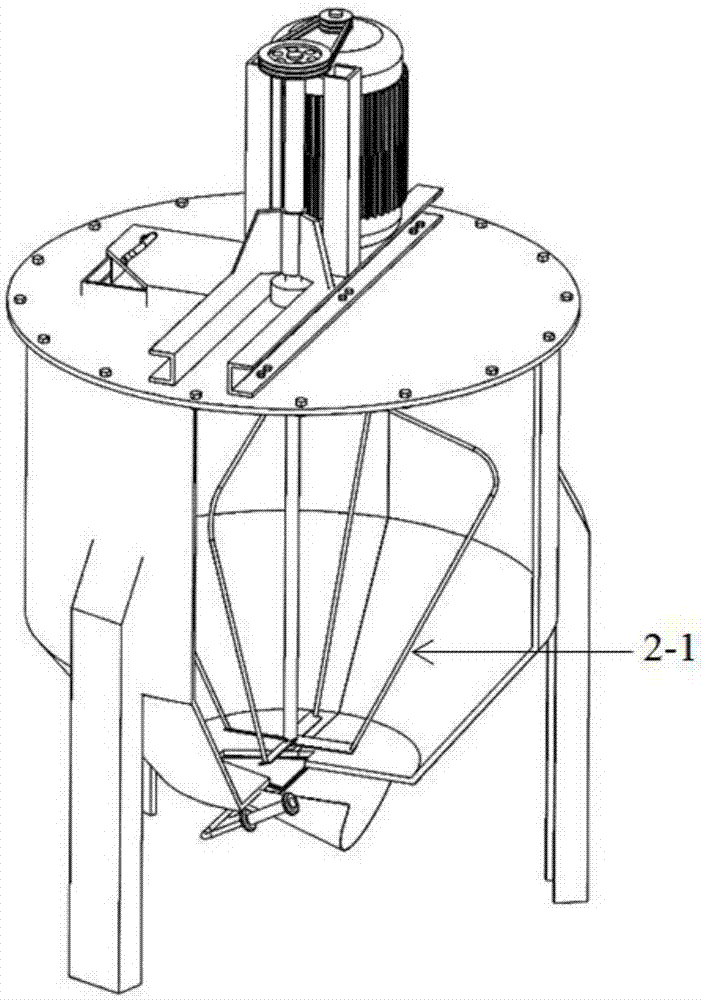

[0030] Such as Figure 4 As shown, the stirring device includes four segments 4-3 with an angle of 45° at the bottom and curved steel bars 4-2 connecting the segments 4-3 to the upper part of the rotating shaft 4-1. The rotating device extends into the mixer container 1-2, and is connected to the power module 1-1 through a bearing....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com