Mechanical stirring type co-coagulation flotation coupled two-layer horizontal sedimentation tank water purifying system and method thereof

A technology of mechanical stirring and copolymerization air flotation, which is applied in the direction of precipitation separation, separation methods, chemical instruments and methods, etc., can solve the problems that the treatment effect is not obvious and the effect is small, so as to improve the collision efficiency and adhesion efficiency and facilitate operation , the effect of reducing water loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

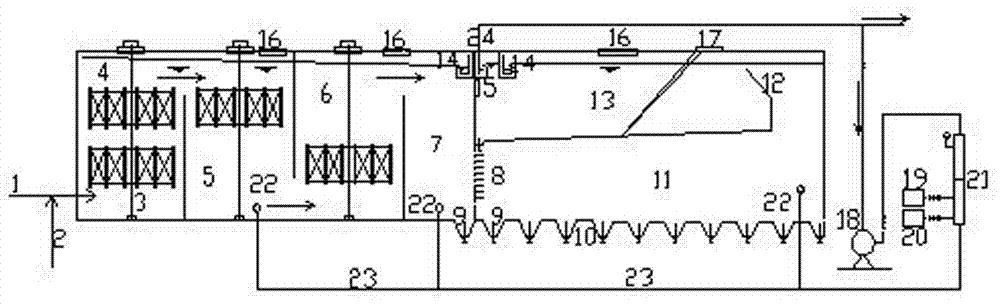

[0043] A mechanical agitation type copolymerization air flotation coupling double-layer advection sedimentation tank water purification system for treating ordinary reservoir water. Connected treatment system, external ozonation dissolved air flotation device and release device, such as figure 1 Shown:

[0044] (1) Three-stage mechanical stirring copolymerization flocculation tank, including three coagulation chambers, which are coagulation 1 chamber 4, coagulation 2 chamber 5 and coagulation 3 chamber 6, coagulation 1 chamber 4 is equipped with two mechanical shafts 3 Coagulation 2 chamber 5 and coagulation 3 chamber 6 are equipped with a mechanical shaft 3, coagulation 1 chamber 4 is connected with water inlet pipe 1; water inlet pipe 1 is connected with dosing pipe 2, and is in the third-stage mechanical stirring copolymerization flocculation tank access at the lower front end. The installation of the mechanical shaft 3 should follow the following requirements: the top of...

Embodiment 2

[0051] A method for processing common reservoir water using the mechanically agitated copolymerized air flotation coupled double-layer advection sedimentation tank water purification system of Embodiment 1, that is, a method for copolymerizing air flotation coupled advection sedimentation water purification, specifically comprising the following steps:

[0052] 1) The raw water enters the three-stage mechanical agitation copolymerization flocculation tank from the lower end of the coagulation 1 chamber 4 pool body through the water inlet pipe 1, and at the same time, the flocculant is added with the raw water through the dosing pipe 2, and the water flows through the three coagulation tanks of the copolymerization mechanical flocculation tank in turn. The coagulation chamber is fully coagulated under the action of the mechanical shaft 3, and through the baffles set between each coagulation chamber, it prevents the short flow of incoming water and ensures sufficient coagulation. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com