SBR-like running method of low load A<2>O technology

An operation method and process technology, which is applied in the field of SBR-like operation of low-load A2O process, can solve the problems of energy waste, decline in facility utilization rate, and greatly improved effluent water quality, and achieve the effect of avoiding design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

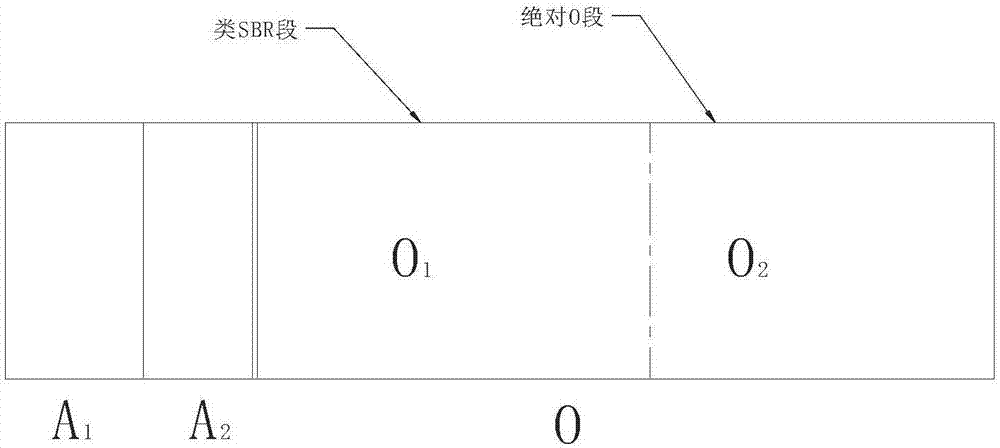

[0033] See figure 1 , which is A in this example 2 O process schematic.

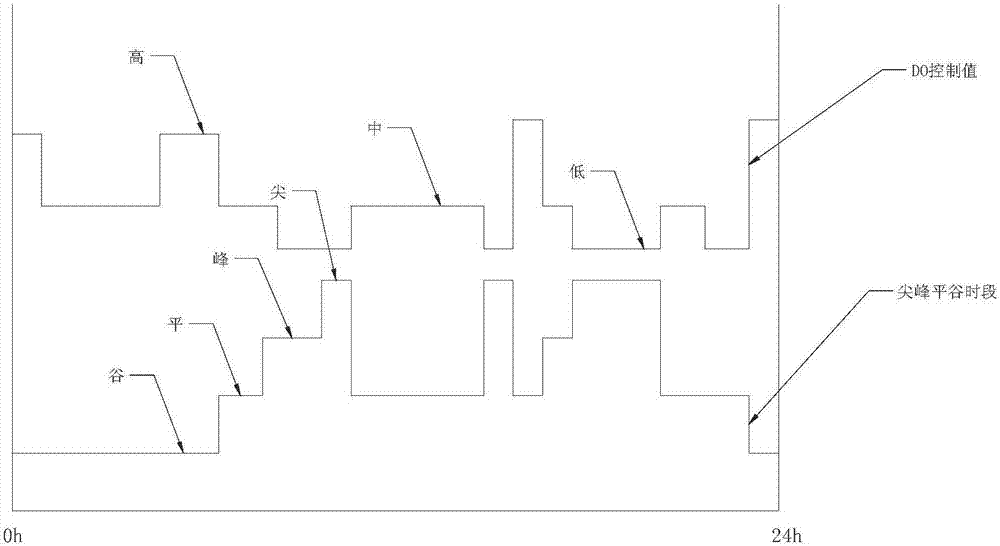

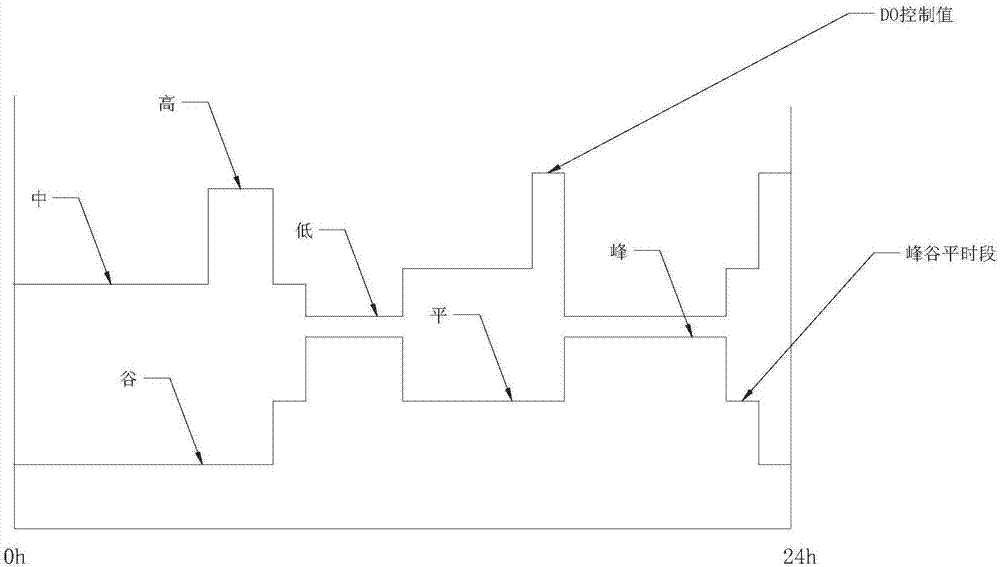

[0034] A 2 O system, the residence time of O pool is 10h, and the designed influent water quality is COD500mg / L, NH 4 + -N is 55mg / L, the actual influent water quality is better than the design value, the influent COD is 200-280mg / L, and the influent NH 4 + -N is 20~30mg / L, that is, the main pollutant index is about 50% of the design value, and it is divided into the front section of the O pool according to the influent flow direction (O 1 ) and after-work section (O 2 ), the function settings are respectively class SBR segment (O 1 ) and the absolute O segment (O 2 ), there is no physical separation between the two sections, and the effective volume of the SBR-like section accounts for 70% of the effective volume of the O pool, and its DO value is set according to Figure 3D The "low-medium" mode is cycled, with the low value set at 0.8mg / L and the medium value set at 2.2mg / L. The effective vo...

Embodiment 2

[0039] See Figure 4 , which is A in this example 2 O process schematic.

[0040] A 2 O system, including anaerobic pools (A 1 pool) 10, anoxic pool (A 2 pool) 20 and aerobic pool (O pool) 30, wherein, according to the water flow direction O pool space is divided into three sections: class SBR section (O pool) 1 ) 31. Absolute aerobic segment (O 2 )32 and hypoxic segment (O 3 )33, wherein the effective volume of the SBR-like section accounts for 35% of the effective volume fraction of the O pool, the effective volume of the absolute O section accounts for 55% of the effective volume fraction of the O pool, and the hypoxic section accounts for 10% of the effective volume fraction of the O pool. The three sections are all separated by the diverting baffle 34 of water flow, and the proportion of direct flow of water flow is about 30%. An aeration pipeline 35 is arranged in the SBR-like section, and the aeration pipeline is provided with a gas flow regulating valve 351 cont...

Embodiment 3

[0044] See Figure 5 , which is A in this example 2 O process schematic.

[0045] A 2 O system, including anaerobic pools (A 1 pool) 10, anoxic pool (A 2 pool) 20 and aerobic pool (O pool) 30, wherein, according to the water flow direction O pool space is divided into two sections: class SBR section (O pool) 1 ) 31. Absolute aerobic segment (O 2 )32, wherein the effective volume of the SBR-like segment accounts for 40% of the effective volume fraction of the O pool, and the absolute O segment effective volume accounts for 60% of the effective volume fraction of the O pool. The two sections are separated by a water flow steering baffle 34, and the direct flow ratio of the water flow is about 35%. An aeration pipeline 35 is arranged in the SBR-like section, and the aeration pipeline is provided with a gas flow regulating valve 351 controlled by an intelligent control system 36 . Moreover, the end of the SBR-like section is provided with a return port 311, and the return p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com