Special Soil Stabilizer Recycling Treatment of Unburned Bricks Made from Municipal Sludge

A municipal sludge and stabilizer technology, applied in the direction of solid waste management, sustainable waste treatment, climate sustainability, etc., can solve the problems of environmental pollution, waste of resources, etc., to achieve reduced usage, lower costs, and good pressure resistance The effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Add 100 parts by weight of municipal wet sludge and 18 parts by weight of quicklime into the first mixing bin to obtain a sludge mixture; the water content of municipal wet sludge is 70%, which is the secondary sedimentation of a sewage treatment plant in Shanghai pool sludge.

[0026] Add solid waste 9 times the volume of the sludge mixture into the first mixing bin, and mix to obtain the primary mixture;

[0027] The primary mixture is stacked for 21 days;

[0028] After mixing 100 parts by weight of the primary mixture and 6 parts by weight of cement in the second mixing bin for 10 minutes, add 0.018 parts by weight of a soil stabilizer and mix for 10 minutes to obtain an unburned brick mixture;

[0029] The unburned brick mixture is pressed into shape at normal temperature and naturally cured to obtain the unburned brick product.

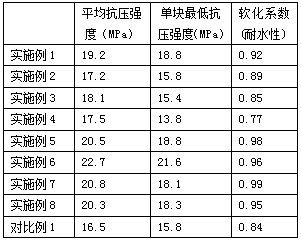

[0030] The finished unfired brick (240×115×90) is tested according to GB8239-97 for the average compressive strength of 5 unfired bric...

Embodiment 2

[0032] Add 100 parts by weight of municipal wet sludge and 18 parts by weight of quicklime into the first mixing bin to obtain a sludge mixture; the water content of municipal wet sludge is 80%, which is the secondary sedimentation of a sewage treatment plant in Xuzhou pool sludge.

[0033] Add solid waste 9 times the volume of the sludge mixture into the first mixing bin, and mix to obtain the primary mixture;

[0034] The primary mixture is stacked for 21 days;

[0035] After mixing 100 parts by weight of the primary mixture and 6 parts by weight of cement in the second mixing bin for 10 minutes, add 0.018 parts by weight of a soil stabilizer and mix for 10 minutes to obtain an unburned brick mixture;

[0036] The unburned brick mixture is pressed into shape at normal temperature and naturally cured to obtain the unburned brick product.

[0037] The finished unfired brick (240×115×90) is tested according to GB8239-97 for the average compressive strength of 5 unfired bricks...

Embodiment 3

[0039] Add 100 parts by weight of municipal wet sludge and 18 parts by weight of quicklime in the first mixing bin to obtain a sludge mixture; the water content of municipal wet sludge is 80%, which is raw sewage from a sewage treatment plant in Hangzhou mud.

[0040] Add solid waste 9 times the volume of the sludge mixture into the first mixing bin, and mix to obtain the primary mixture;

[0041] The primary mixture is stacked for 21 days;

[0042] After mixing 100 parts by weight of the primary mixture and 6 parts by weight of cement in the second mixing bin for 10 minutes, add 0.018 parts by weight of a soil stabilizer and mix for 10 minutes to obtain an unburned brick mixture;

[0043] The unburned brick mixture is pressed into shape at normal temperature and naturally cured to obtain the unburned brick product.

[0044] The finished unfired brick (240×115×90) is tested according to GB8239-97 for the average compressive strength of 5 unfired bricks, the minimum value of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com