Dealcoholizing type room temperature vulcanized silicone rubber rosin modified organosilane crosslinking agent and preparation method thereof

A technology for organosilane and rosin modification, which is applied in chemical instruments and methods, organic chemistry, compounds of group 4/14 elements of the periodic table, etc., and can solve the problem of poor mechanical properties of condensation-type room temperature vulcanized silicone rubber and silicone rubber molecules. The chain flexibility is large, the intermolecular force is small, etc., to make up for the poor mechanical properties of silicone rubber, the preparation is simple, and the mechanical properties are improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

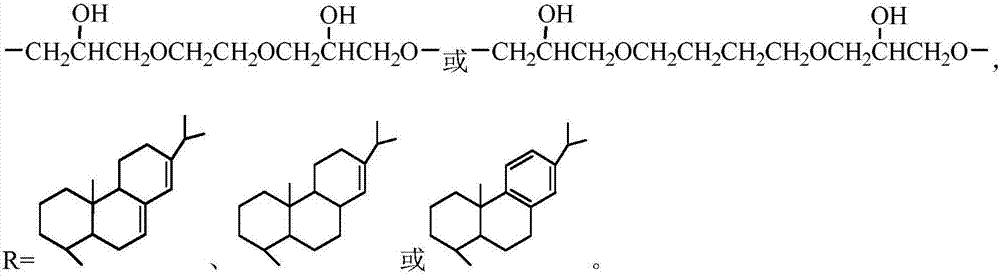

[0024] Weigh 50 parts of refined rosin glycidyl ester and 31 parts of aminopropyltriethoxysilane into a three-necked flask, and react at 60°C for 1.5 h under nitrogen protection and stirring at 300 rpm to synthesize refined rosin glycidyl ester. Aminopropyltriethoxysilane crosslinker.

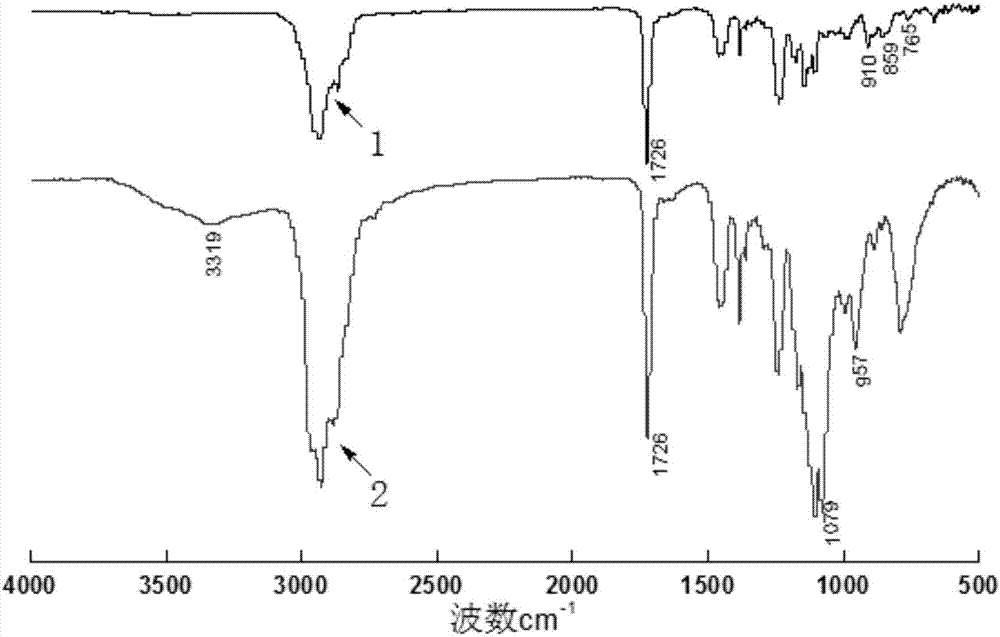

[0025] FT-IR spectrum identification of refined rosin glycidyl ester and refined rosin glycidyl ester modified aminopropyltriethoxysilane crosslinking agent:

[0026] Refined rosin glycidyl ester: 1726cm -1 Carbonyl characteristic absorption peak, 765cm -1 、859cm -1 、910cm -1 It is the characteristic absorption peak of epoxy group; refined rosin glycidyl ester modified aminopropyl triethoxysilane crosslinking agent: 3319cm -1 It is the characteristic absorption peak of nitrogen-hydrogen bond, 1079cm -1 It is the characteristic absorption peak of silicon oxygen carbon bond, 957cm -1 It is the characteristic absorption peak of ethoxy group. From the comparative analysis of the characterist...

Embodiment 2

[0029] Weigh 50 parts of dehydroabietic acid glycidyl ester and 31 parts of aminopropyltriethoxysilane into a three-necked flask, and react at 40°C for 3 hours under nitrogen protection and stirring at 300 rpm to synthesize dehydroabietic acid glycidyl ester Glyceride modified aminopropyltriethoxysilane crosslinker.

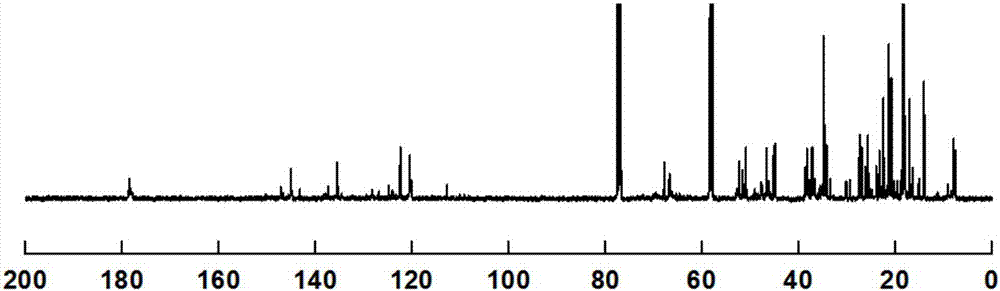

[0030] Dehydroabietic acid glycidyl ester modified aminopropyltriethoxysilane crosslinking agent 13 CNMR spectrum identification: in the range of 120-145ppm, it belongs to the C=C characteristic chemical shift peak in the phenanthrene ring structure of the rosin structure, 178ppm belongs to the C=O characteristic chemical shift peak, 67ppm belongs to the O-C characteristic chemical shift peak, 58 and 18ppm respectively It belongs to the characteristic chemical shift peak of Si-O-C-C, and 48ppm belongs to NH-CH 2 The characteristic chemical shift peak, 10-55ppm belongs to the characteristic chemical shift peak of other carbon atoms in the rosin structure. pass ...

Embodiment 3

[0032] Weigh 50 parts of hydrogenated rosin glycidyl ester and 31 parts of aminopropyltriethoxysilane into a three-necked flask, and react at 35°C for 6 hours under nitrogen protection and stirring at 300 rpm to synthesize hydrogenated rosin glycidyl ester modified Aminopropyltriethoxysilane crosslinker.

[0033] Hydrogenated rosin glycidyl ester modified aminopropyltriethoxysilane crosslinking agent 13 CNMR spectrum identification: 120 and 146ppm belong to the CH=C characteristic chemical shift peak in the phenanthrene ring structure of the rosin structure, 178ppm belongs to the C=O characteristic chemical shift peak, 70ppm belongs to the O-C characteristic chemical shift peak, 58 and 18ppm belong to Si -O-C-C characteristic chemical shift peak, 48ppm belongs to NH-CH 2 The characteristic chemical shift peak, 10-55ppm belongs to the characteristic chemical shift peak of other carbon atoms in the rosin structure. pass 13 CNMR spectrogram analysis, the results show that hydr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com