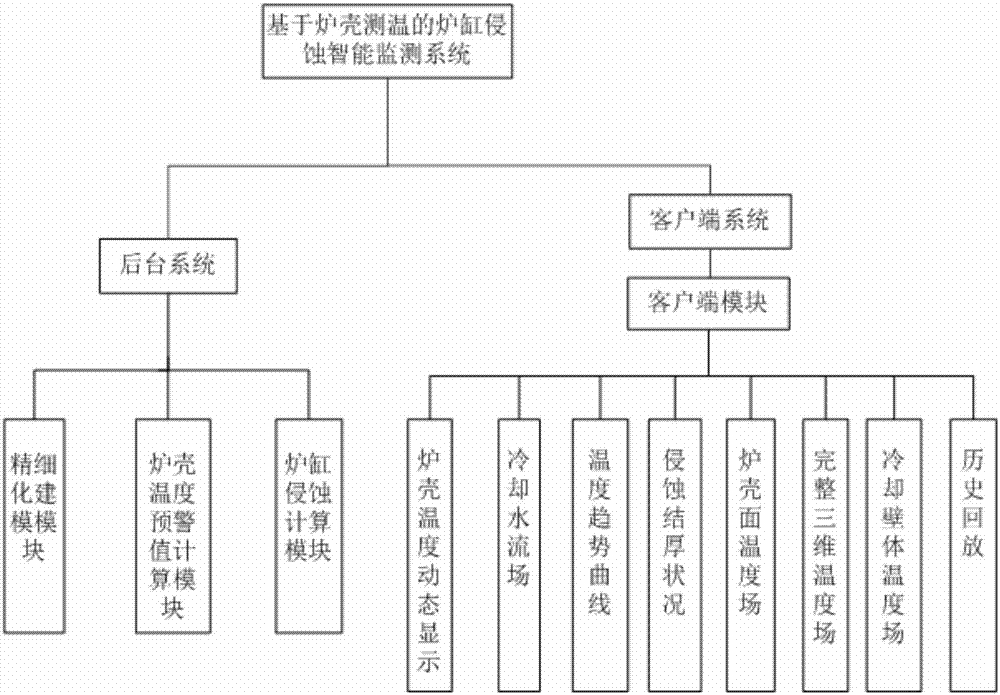

Intelligent monitoring system monitoring hearth erosion condition based on furnace shell temperature measuring

An intelligent monitoring and furnace shell technology, applied in sustainable manufacturing/processing, inspection devices, climate sustainability, etc., can solve the problems of stress waves that cannot pass through, large difference, misjudgment, etc., and achieve long life and operation of blast furnaces Low cost and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] According to the arrangement of cooling walls in the hearth area of the blast furnace, formulate a reasonable layout plan for the temperature measurement points of the furnace shell, collect the temperature data of the furnace shell, establish an ORACLE data table to store the data, filter and store the collected data, and conduct fine-tuning based on the structure of the blast furnace hearth Combined with heat transfer science, the calculation of the early warning value of the furnace shell temperature and the dynamic simulation of the hearth erosion and thickening process are carried out. Finally, the calculation results are displayed in the form of images through the client to monitor the erosion status in the furnace.

[0025] 1. Furnace shell temperature data collection

[0026] According to the distribution and specific conditions of the corresponding blast furnace hearth staves, the best furnace shell temperature measurement layout scheme is formulated. Researc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com