Fluid switching electromagnetic valve and endoscope with same

A solenoid valve and endoscope technology, applied in the field of medical devices, can solve the problems of reducing the volume of the operating part, the electrical influence of the circuit board, increasing the weight of the operating part, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

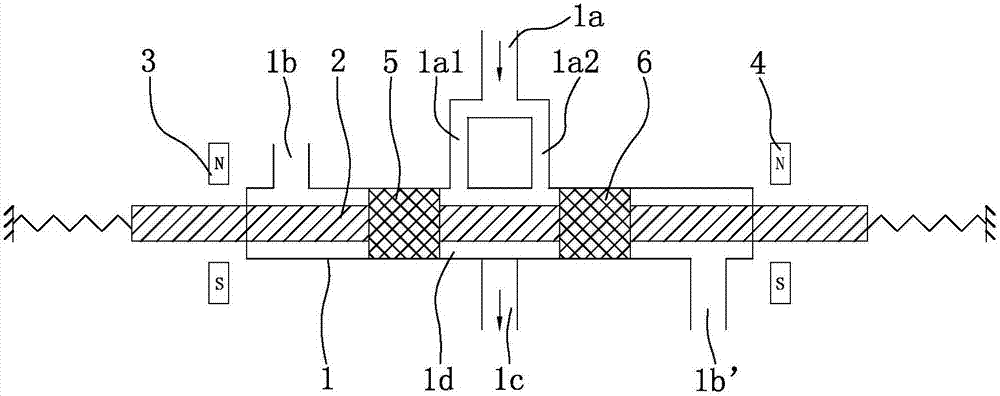

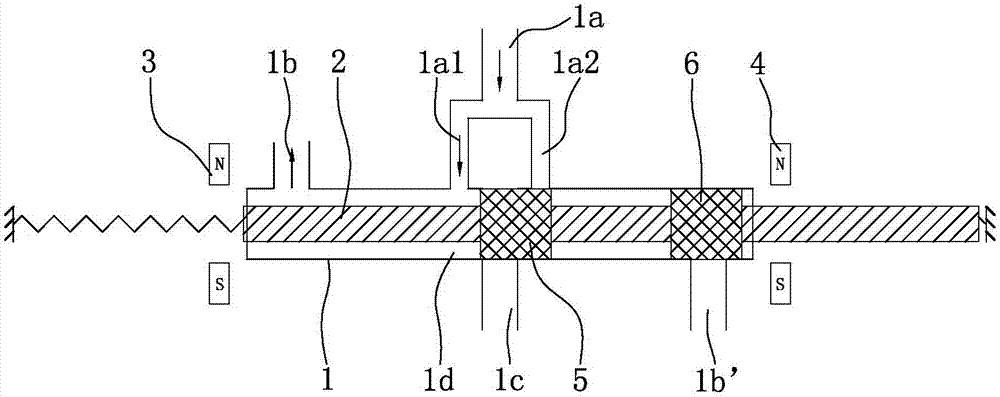

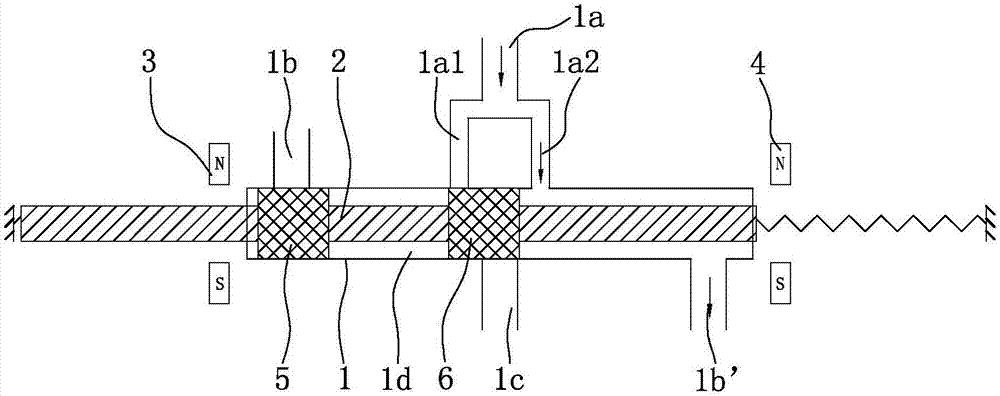

[0032] Such as figure 1 , figure 2 , image 3 As shown, the electromagnetic valve in the present invention is composed of a valve body 1, a valve core 2, a first coil 3, a second coil 4, a first sealing ring 5 and a second sealing ring 6, and the like. Among them, the main air channel 1d of the valve body 1 is a straight pipe structure, and an air inlet 1a and an air port 1c are arranged in the middle of the valve body 1, the air inlet 1a is located on one side of the valve body 1, and the air port 1c is located on the valve body 1 The other side, and the air port 1c is facing the air inlet 1a. Of course, as an equivalent alternative, the air inlet 1a and the air port 1c can also be arranged on the same side of the valve body 1, or the position of each air port on the valve body 1 can be set according to actual needs. The outlet end of the air inlet 1a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com