Test device and method for simulating fractured rock secondary diagenesis

A test device and rock mass technology, applied in the direction of measuring devices, mechanical devices, instruments, etc., can solve problems such as troublesome sampling process, lack of reliable theoretical basis for support, and influence of mechanical parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below.

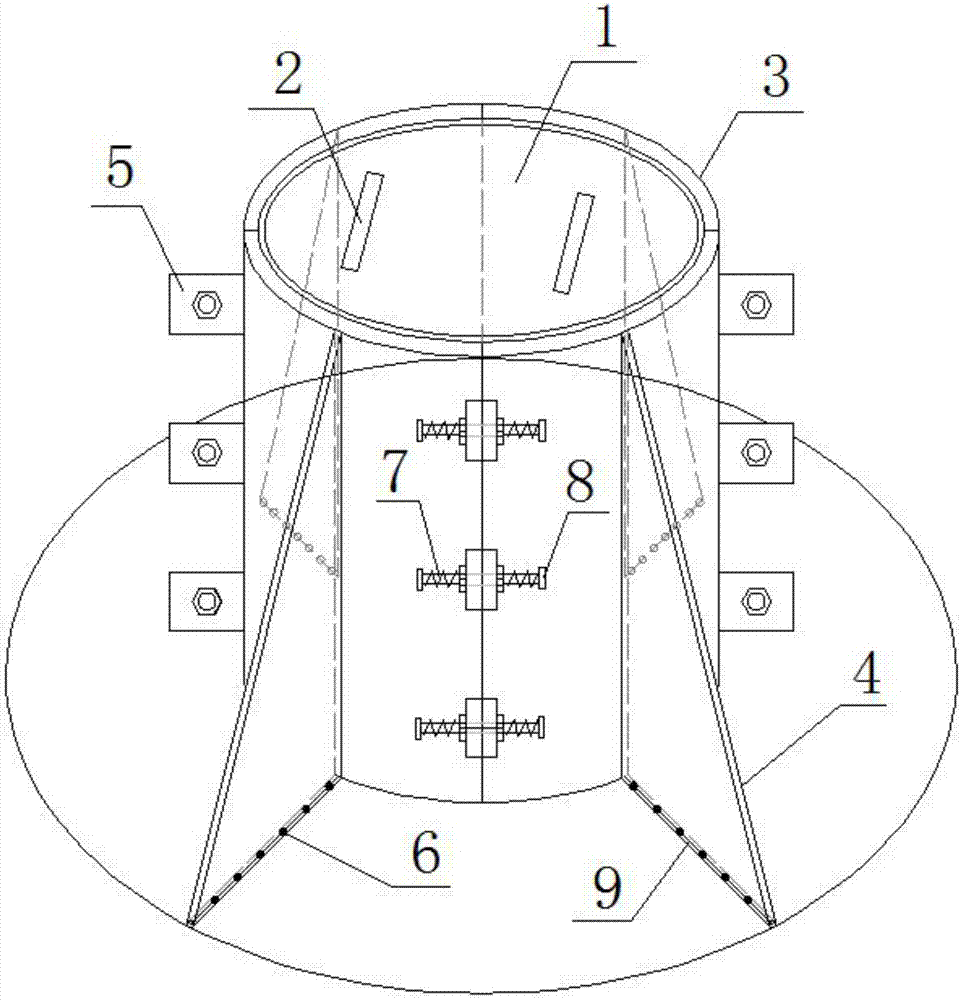

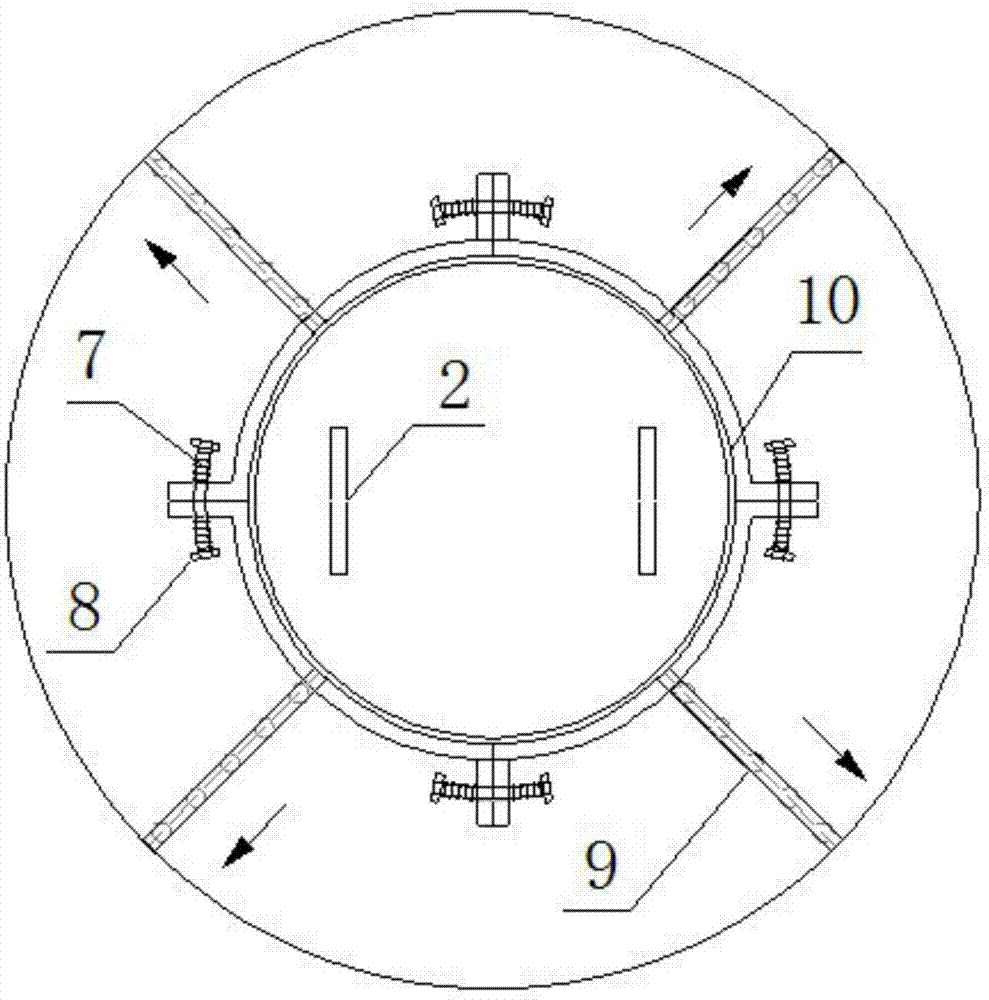

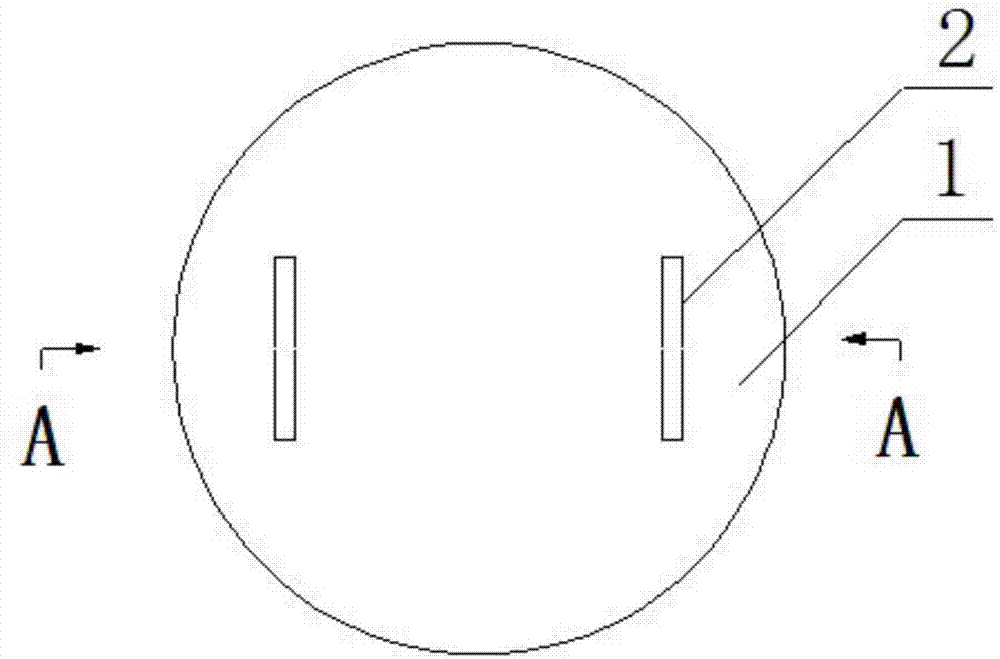

[0031] Such as Figure 1 to Figure 10 As shown, a test device for simulating the secondary diagenesis of a broken rock mass includes an axial pressure plate 1, a confining pressure device, a chassis and a confining pressure applicator. On the pressure plate 10, the confining pressure device is a cylinder formed by splicing a plurality of arc-shaped plates 3 of the same shape. A plurality of confining pressure transmission pins 5 are arranged on both sides of the arc-shaped plate 3, and the confining pressure transmission The center of the pin 5 is provided with a mounting hole, and the confining pressure applicator is composed of a pressure rod and a pressurizer 7, the pressure rod passes through two overlapping mounting holes on the adjacent arc plate 3, and the pressure device 7 is set On the pressing rod; the shaft pressure plate 1 is arranged above the cylinder, and the diameter of the shaft pressure plate 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com