A kind of ozone catalytic oxidation catalyst modification method

An ozone catalytic oxidation and catalyst technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve the problems of low catalytic efficiency and reduction, and achieve improved catalytic efficiency. Efficiency, simple operation steps, mild effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

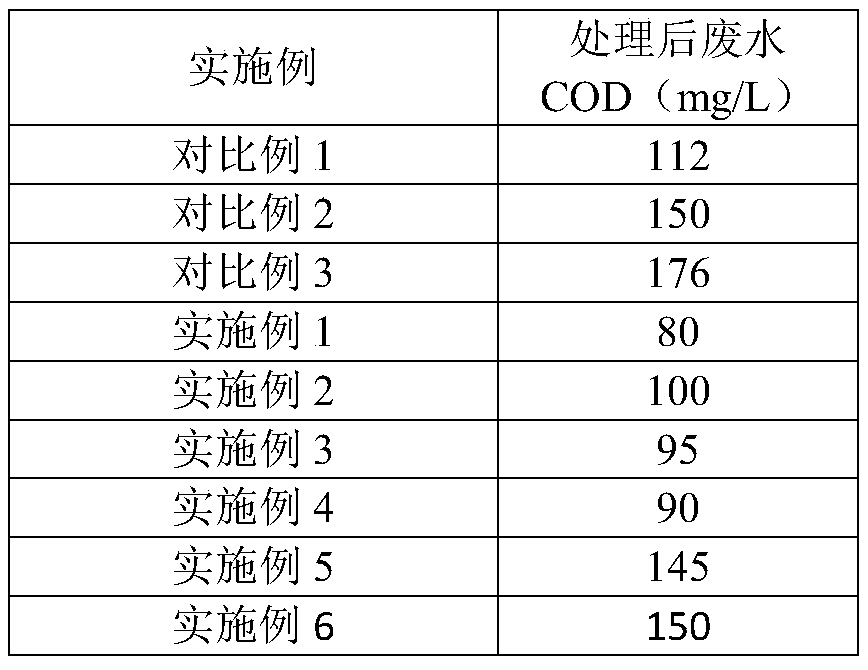

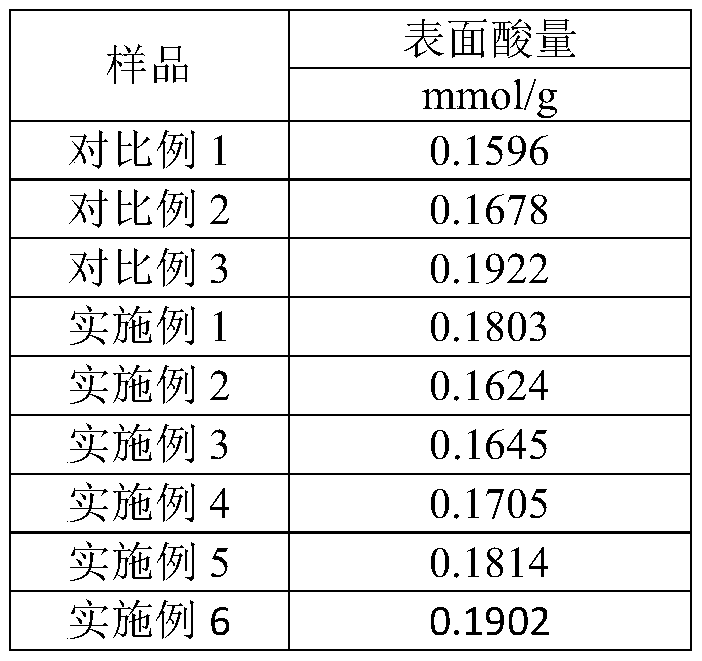

Examples

Embodiment 1

[0028] The catalyst obtained in Comparative Example 1 was modified by ammonium nitrate solution with a mass fraction of 5%, impregnated according to catalyst:solution mass ratio = 1:3, treated at room temperature for 6 hours; washed after filtration, dried at 120°C for 15 hours, and calcined at 500°C for 4 hours , to obtain the modified catalyst.

Embodiment 2

[0030] The catalyst obtained in Comparative Example 1 was modified by ammonia water with a mass fraction of 5%, impregnated according to catalyst:solution mass ratio = 1:3, treated at room temperature for 6 hours; washed after filtration, dried at 120°C for 15 hours, and calcined at 500°C for 4 hours to obtain modified catalyst.

Embodiment 3

[0032] The catalyst obtained in Comparative Example 1 was modified by hydrogen peroxide with a mass fraction of 5%, impregnated according to catalyst:solution mass ratio = 1:3, treated at room temperature for 6 hours; washed after filtration, dried at 120°C for 15 hours, and calcined at 500°C for 4 hours to obtain modified catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com