Preparation method of petal shaped ZnCo2O4 nanometer solid material with meso pores

A solid material and petal-shaped technology, which is applied in the field of preparation of mesoporous petal-shaped ZnCo2O4 nano-solid materials, can solve the problems that the influencing factors are difficult to control, cannot be obtained, and the operation process is complicated.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

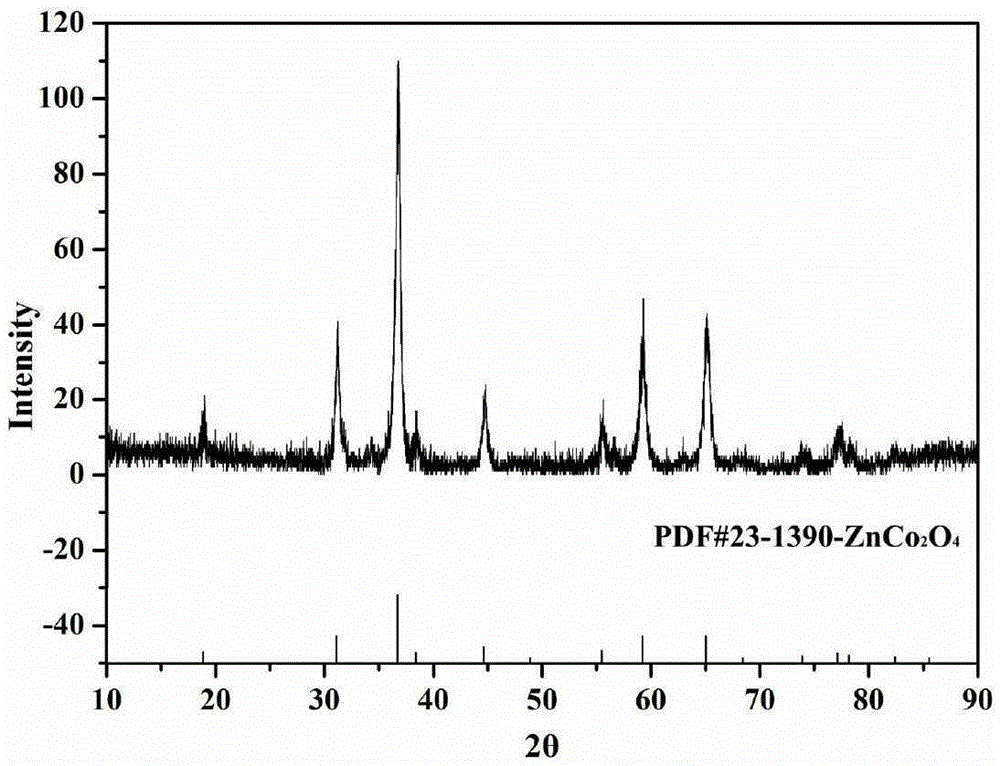

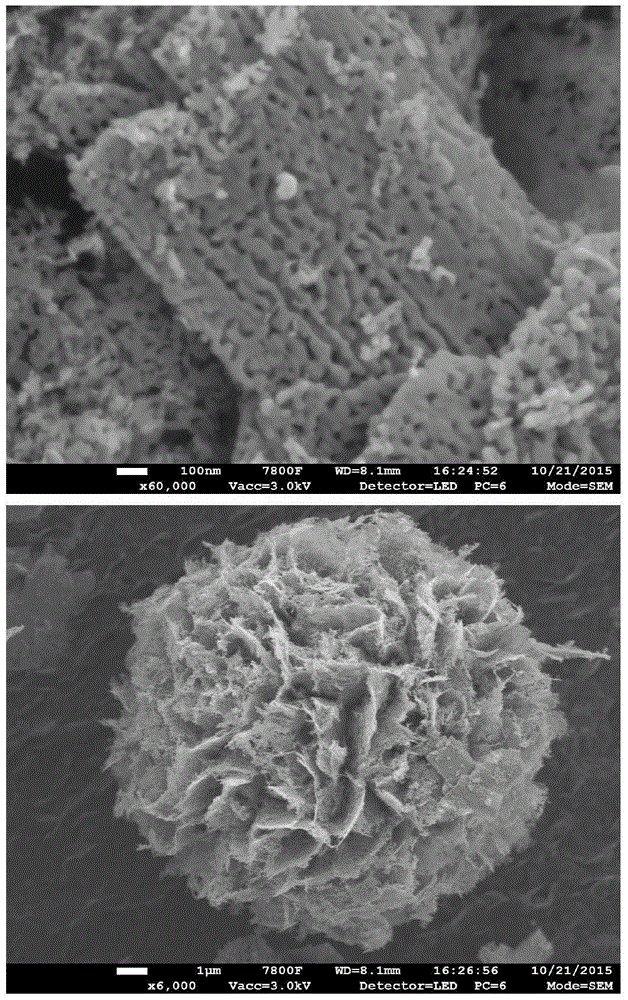

[0017] At room temperature, dissolve 1mmol of zinc chloride, 2mmol of cobalt chloride and 12mmol of urea in 50ml of water and 30ml of ethanol, place on a magnetic stirrer, stir fully to dissolve them all. After stirring for 30 minutes, the solution was transferred to a 100ml stainless steel high-temperature and high-pressure reactor with a polytetrafluoroethylene liner, placed in a muffle furnace for hydrothermal reaction at 160°C for 18 hours, and then cooled to room temperature. The resulting product was washed with absolute ethanol Wash three times to remove possible residual impurities, centrifugally filter, and vacuum-dry at 60°C. The dried product was calcined at 500° C. for 2 h in an air atmosphere. Obtained mesoporous petal-like ZnCo 2 o 4 Nanosolid materials (such as figure 1 , figure 2 shown).

Embodiment 2

[0019] At room temperature, dissolve 1mmol of zinc chloride, 2mmol of cobalt chloride and 12mmol of urea in 50ml of water and 30ml of ethanol, place on a magnetic stirrer, stir fully to dissolve them all. After stirring for 30 minutes, the solution was transferred to a 100ml stainless steel high-temperature and high-pressure reactor with a polytetrafluoroethylene liner, placed in a muffle furnace for hydrothermal reaction at 120°C for 12 hours, then cooled to room temperature, and the resulting product was washed with absolute ethanol Wash three times to remove possible residual impurities, centrifugally filter, and vacuum-dry at 60°C. The dried product was calcined at 400° C. for 2 h in an air atmosphere. Get ZnCo 2 o 4 nano-solid materials.

Embodiment 3

[0021] At room temperature, dissolve 1mmol of zinc sulfate, 2mmol of cobalt sulfate and 15mmol of urea in 50ml of water and 30ml of ethanol, place on a magnetic stirrer, and stir fully to dissolve them all. After stirring for 30 minutes, transfer the solution to a 100ml stainless steel high-temperature and high-pressure reactor with a polytetrafluoroethylene liner, place it in a muffle furnace for hydrothermal reaction at 180°C for 24 hours, and then cool to room temperature. Wash three times to remove possible residual impurities, centrifugally filter, and vacuum-dry at 60°C. The dried product was calcined at 600° C. for 30 min in an air atmosphere. Get ZnCo 2 o 4 nano-solid materials.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap