Purification method for decoloring and deproteinizing Scholar bean polysaccharide

A purification method and deproteinization technology, which is applied in the field of purification of champion bean polysaccharide decolorization and deproteinization, can solve the problems of large amount of reagents, multiple repetitions, high inactivation temperature, etc., and achieve simple and time-saving operation, avoid organic solvents, and process safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

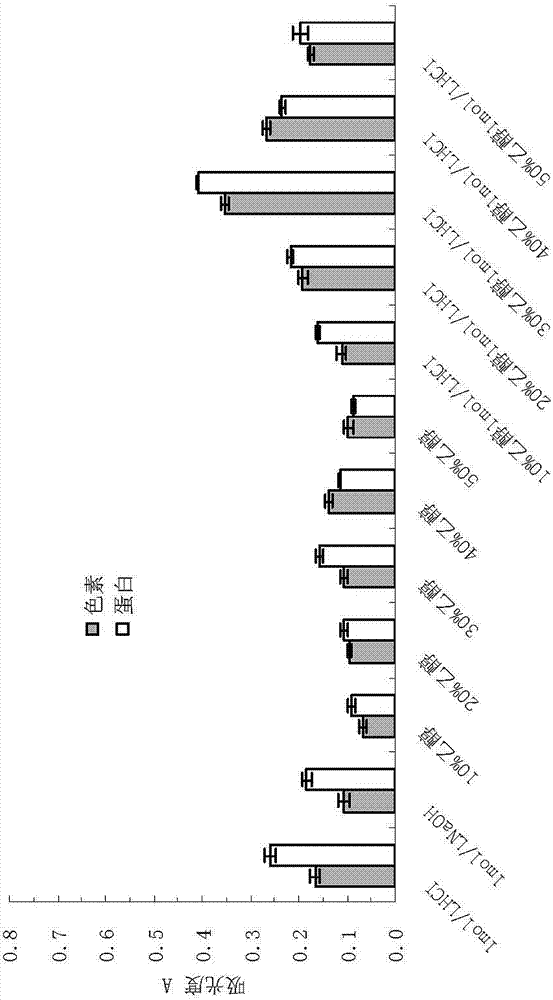

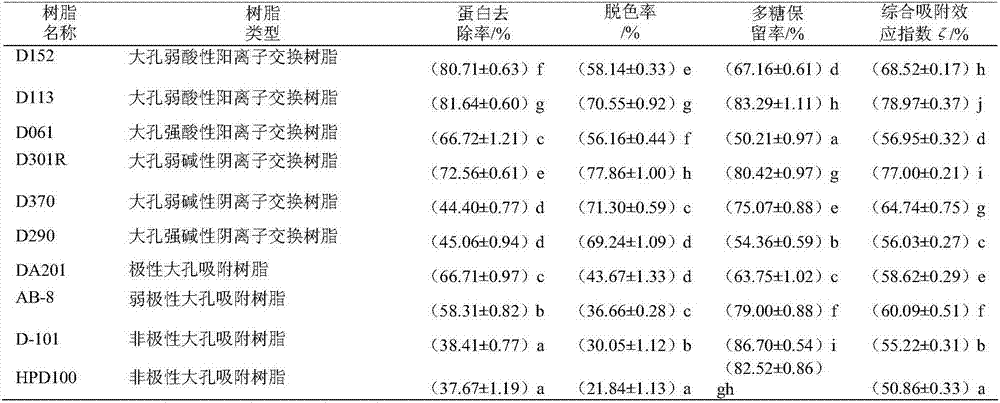

[0021] The present invention takes the decolorization rate, protein removal rate and polysaccharide retention rate as comprehensive evaluation indicators, and introduces a comprehensive effect index to objectively evaluate the adsorption performance of 10 kinds of macroporous resins on the crude polysaccharide protein and pigment of the champion bean, and screen out the resin with the best effect , On this basis, the decolorization and deproteinization process conditions of D113 macroporous resin were analyzed and optimized through single factor test and Design-Expert software, and the regeneration conditions of D113 resin were investigated.

[0022] Concrete steps of the present invention are:

[0023] 1. Extraction of champion bean polysaccharide

[0024] Dry the champion beans at 105°C to constant weight, crush them through a 40-mesh sieve, and reflux them in a Soxhlet extractor for 4 hours to remove esters, take them out, and ventilate and dry. The reflux extraction solve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com