Graphene three-dimensional composite water-based electrothermal ink and preparation method thereof

An electrothermal ink and three-dimensional composite technology, which is applied in ink, household appliances, applications, etc., can solve problems such as re-graphitization and electrothermal conversion efficiency attenuation, and achieve the effects of alleviating resistance attenuation, overcoming power attenuation, and maintaining stable heating performance for a long time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

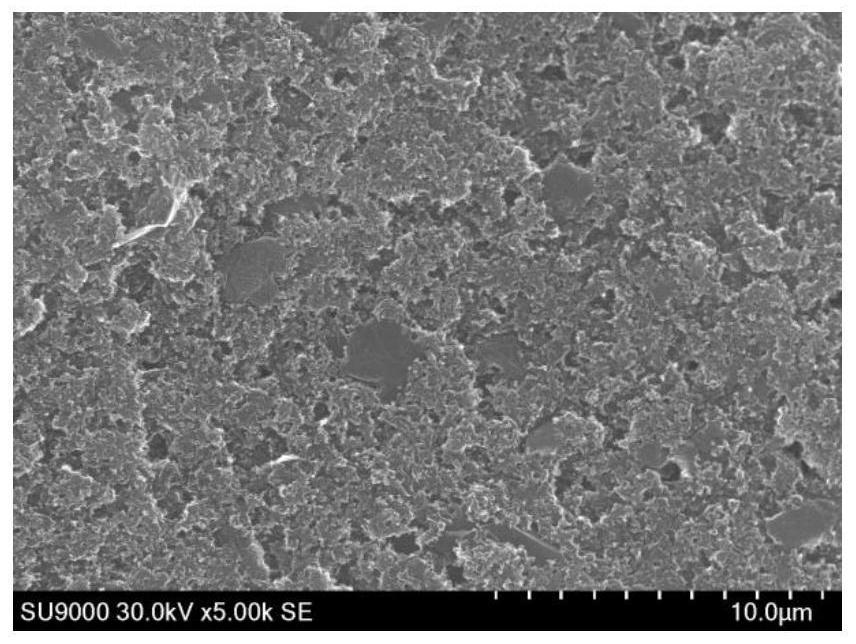

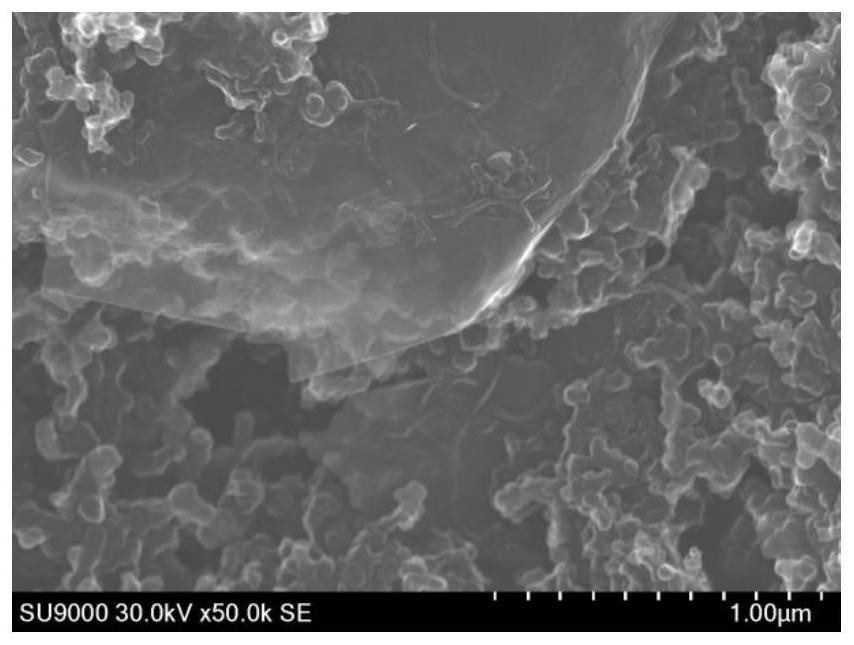

[0038] like Figure 1-2 As shown in the figure, a graphene three-dimensional composite water-based electrothermal ink of the present invention is characterized in that: it includes a graphene dispersion liquid, a carbon nanotube dispersion liquid, a carbon black dispersion liquid, a first water-based resin, a first dispersant and a second dispersant .

[0039] The graphene, carbon nanotubes and carbon black form a three-dimensional stable structure through the combination of graphene and carbon nanotubes, and then the carbon black nanoparticles are arranged in the gap, which fundamentally solves the problem of long-term use of the electric heating film. The re-graphitization problem that occurs solves the big problem that the graphitization leads to the attenuation of the electrothermal conversion efficiency. These three materials form a skeleton network, which changes from simple surface-to-surface contact to point-to-point contact, point-to-line contact, line-to-surface con...

Embodiment 2

[0040] Embodiment 2, a preparation method of a graphene three-dimensional composite water-based electrothermal ink of the present invention is characterized in that the specific steps are:

[0041] (1) Preparation of graphene ink separation:

[0042] (1) Get the graphene powder of 0.1-10 parts by weight, add 90-120 parts by weight of pure water at a speed of 5-10 parts by weight / min under stirring, be warming up to 25 ℃~100 ℃ after adding, keep down-spin Stir and keep the temperature constant for 10 hours;

[0043](2) adding the first dispersant of 0.1-5 parts by weight at a speed of 0.1-1 parts by weight / min, heating up to 25 ℃~100 ℃ after adding, keeping the downward stirring, and the temperature is constant for 46-50 hours;

[0044] (3) Discharge after cooling to normal temperature;

[0045] (2) Preparation of multi-wall carbon nanotube ink separation:

[0046] (1) Get 4-10 parts by weight of multi-walled carbon nanotube powder, add 90-120 parts by weight of pure water a...

Embodiment 3

[0058] Embodiment 3, on the basis of the above embodiment, in the step (4), including steps:

[0059] (11) The graphene ink liquid separation obtained in the step (1) and the multi-walled carbon nanotube ink liquid separation obtained in the step (2) are mixed according to 1:1, and the obtained mixed solution is mixed with 5-10 wt. Add the first water-based resin at a rate of parts per minute, heat up to 70°C to 90°C at a constant speed of 2-6°C / min, keep stirring at 1500-2000rpm / min, and maintain a constant temperature for 0.8-1.5 hours;

[0060] (12) The graphene-carbon nanotube mixed solution obtained in the step (11) and the multi-walled carbon nanotube ink liquid separation obtained in the step (2) are mixed according to 2:1, and the obtained mixed solution is mixed with 5 -Add the first water-based resin at a rate of 10 parts by weight / min, heat up to 70°C to 90°C at a constant speed of 2-6°C / min, keep stirring at 1500-2000rpm / min, and keep the temperature constant for 0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com