Split air conditioner for ship

A split-type, air-conditioning technology, which is applied in air-conditioning systems, hull ventilation/heating/cooling, applications, etc. It can solve the problems of low heating capacity, condensation at the air outlet, and icing of outdoor unit condensers. Effects of condensate discharge capacity, stable heating capacity, and strong corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing, the specific embodiment of the present invention is described in further detail:

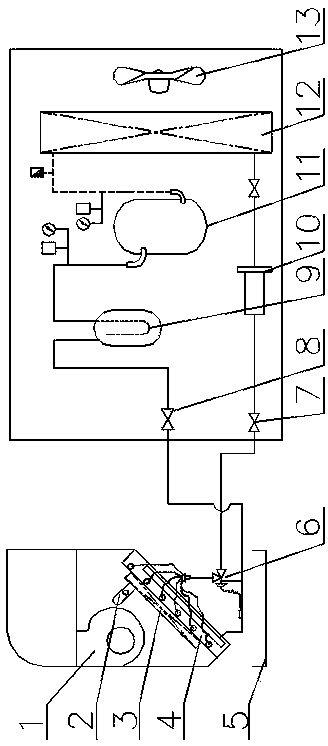

[0015] Such as figure 1 As shown, a split-type air conditioner for ships includes two parts: an indoor unit and an outdoor unit. The indoor unit includes a centrifugal fan 1, a temperature control switch 2, a heater 3, an evaporator 4, a water pan 5 and an expansion valve 6. The evaporator 4 is a copper finned evaporator, a water pan 5 is arranged directly below the evaporator 4, a heater 3 is installed on the top surface of the evaporator, and a temperature control switch 2 is arranged on the heater. A centrifugal fan 1 is provided above the evaporator; the outdoor unit includes a liquid supply stop valve 7, a fluorine stop valve 8, a gas-liquid separator 9, a dry filter 10, a compressor 11, a condenser 12, a spiral fan 13, and copper fins. The chip condenser 12 is arranged in the shell of the outdoor unit near the air outlet. The li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com