Flat specimen high-temperature tension-compression fatigue test clamp and method

A fatigue test and test piece technology, which is used in the application of repetitive force/pulsation force to test the strength of materials, measuring devices, instruments, etc. Extensive/compressive fatigue test requirements, etc., to achieve the effect of low stress level and high material performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

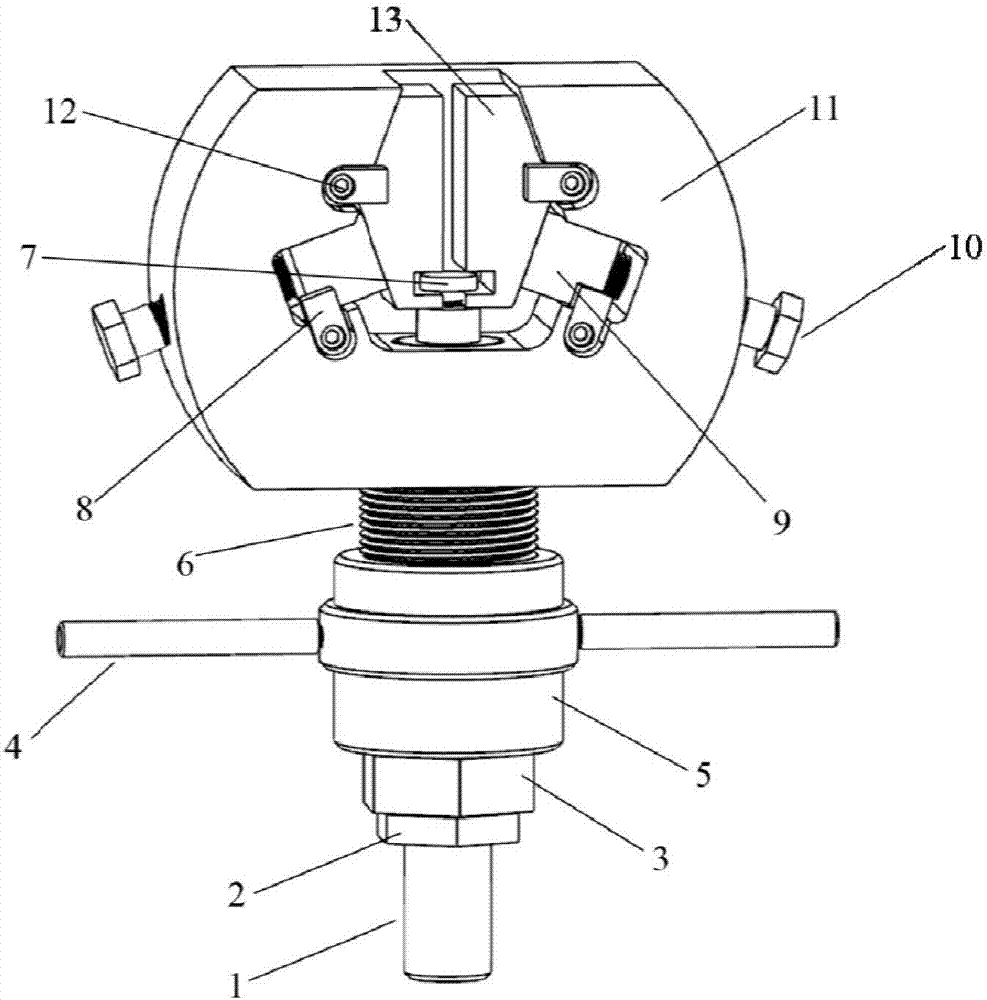

[0047] The invention mainly designs high-temperature fatigue fixtures suitable for flat test pieces and capable of performing tension / compression tests. In fact, during the test, the whole set of fixtures includes two fixtures of the present invention, which are divided into upper fixtures and lower fixtures. The general diagram of complete installation is shown in Figure 15 .

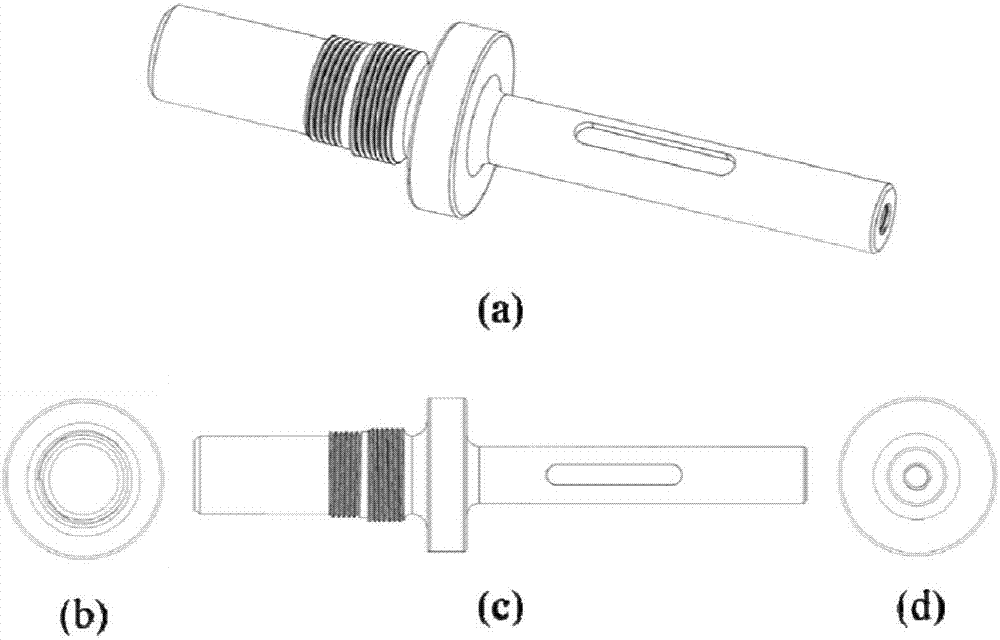

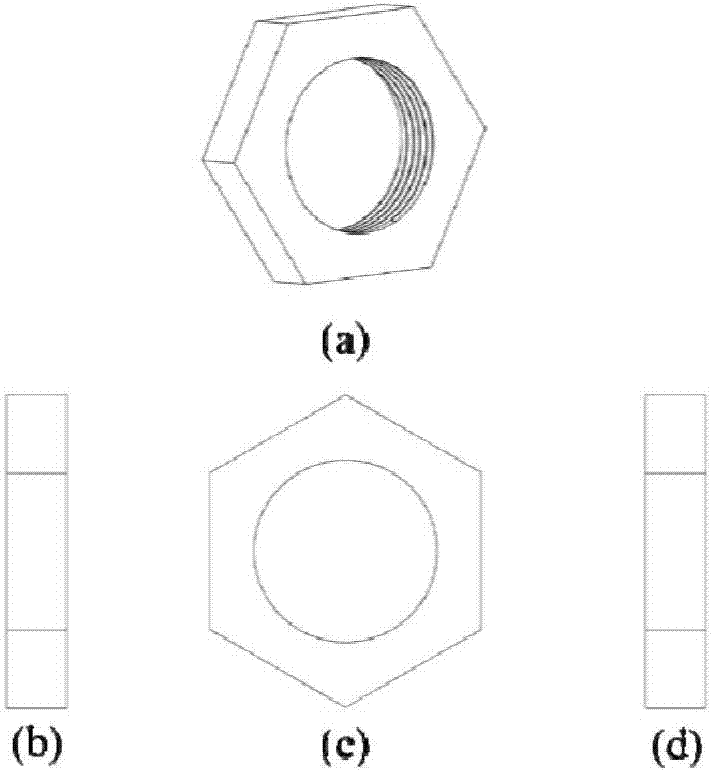

[0048] The fixture includes the following parts: central shaft 1, left-handed nut 2, right-handed nut 3, sleeve rod 4, sleeve 5, connecting rod 6, guide table 7, stop piece 8, square clamp block 9, locking bolt 10, wedge Clamp body 11, countersunk head bolt 12, wedge-shaped clamp block 13.

[0049] Among them, such as figure 1 As shown, the static positional relationship between the various components is: the wedge-shaped clamp body 11 and the connecting rod 6 are threadedly connected, and the upper surface of the thick end of the connecting rod 6 is in contact with the lower surface of the wedge-sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com