Mini ultrahigh-frequency anti-metal electronic label and manufacturing method thereof

An electronic label and ultra-high frequency technology, which is applied to record carriers used in machines, instruments, computer parts, etc., can solve problems such as inability to meet user needs, difficult processing of ceramic materials, and low production efficiency, and achieve excellent metal resistance properties , convenient communication, convenient installation and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] In order to make the technical means, creative features, objectives and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

[0051] This example provides a UHF, readable and writable miniature UHF anti-metal electronic tag, which is a passive backscatter tag that meets the air interface requirements of ISO / IEC 18000-6C, and its working frequency range covers 860 MHz– 928 MHz.

[0052] In mass production, several labels need to be designed in a large material layout, arranged in a matrix according to the process requirements, and then cut into independent electronic labels after completion.

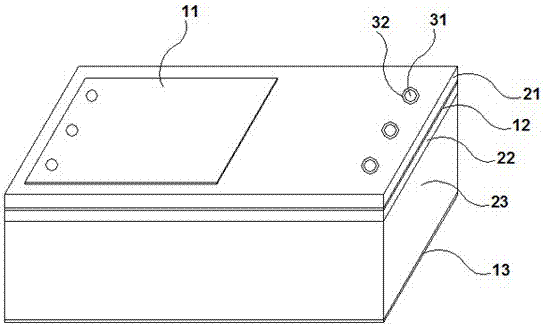

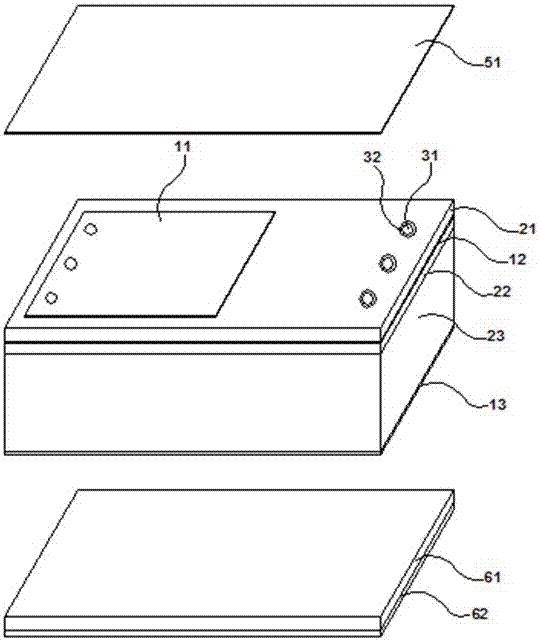

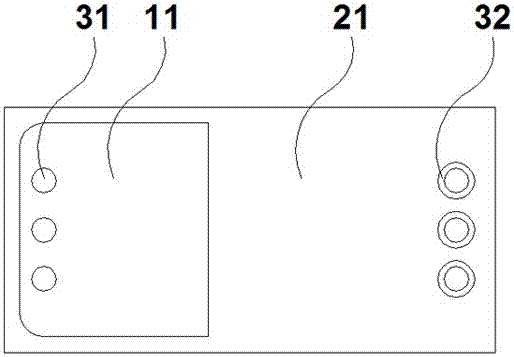

[0053] see figure 1 , which is a schematic structural diagram of the miniature UHF anti-metal electronic tag. As can be seen from the figure, the radio frequency tag is mainly composed of:

[0054] The first antenna layer 11 is composed of conductive antenna patterns arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com