Oil-cooled battery pack

A battery pack, liquid-cooled battery technology, applied in secondary batteries, battery caps/end caps, battery pack components, etc. problem, to achieve the effect of increasing the heat dissipation effect, simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

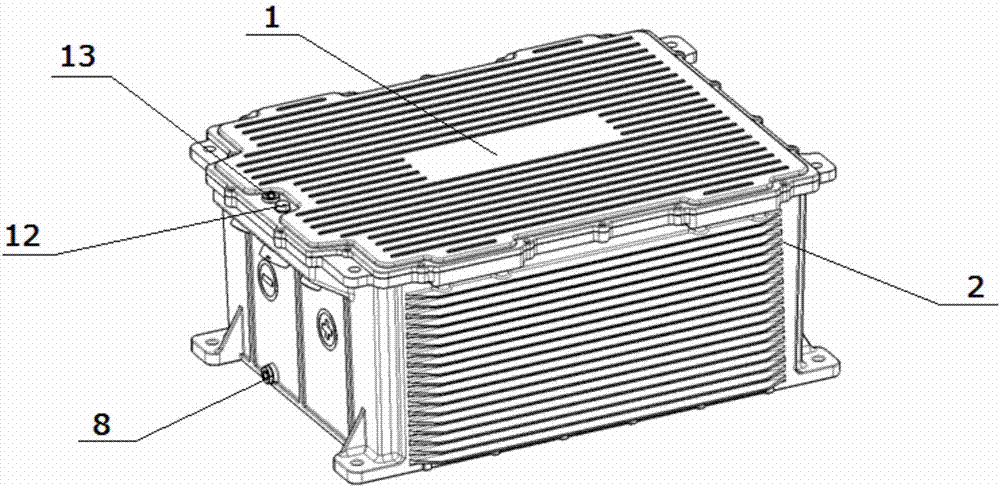

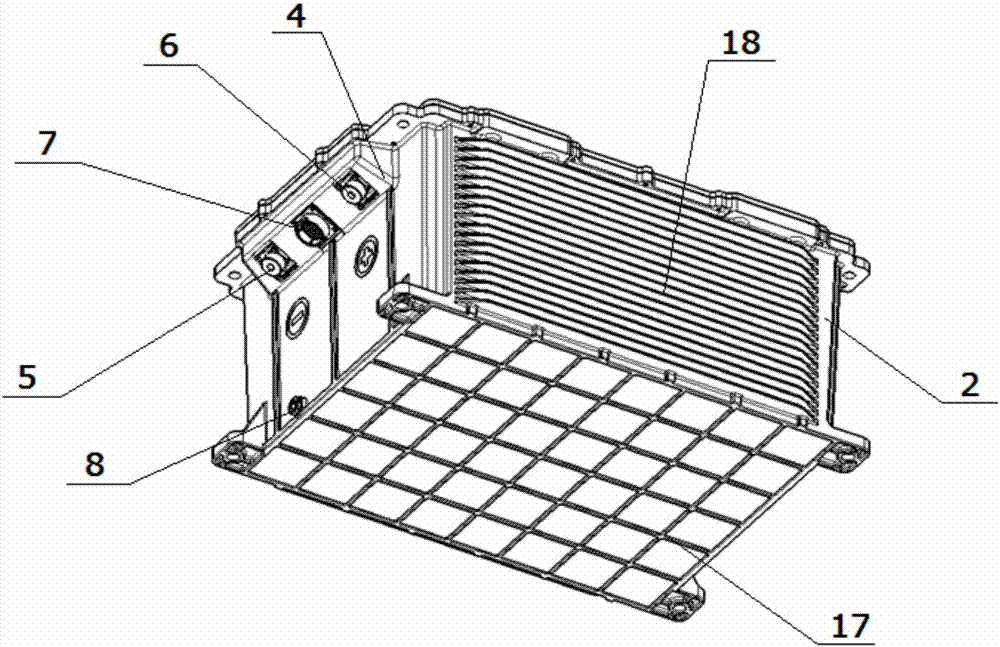

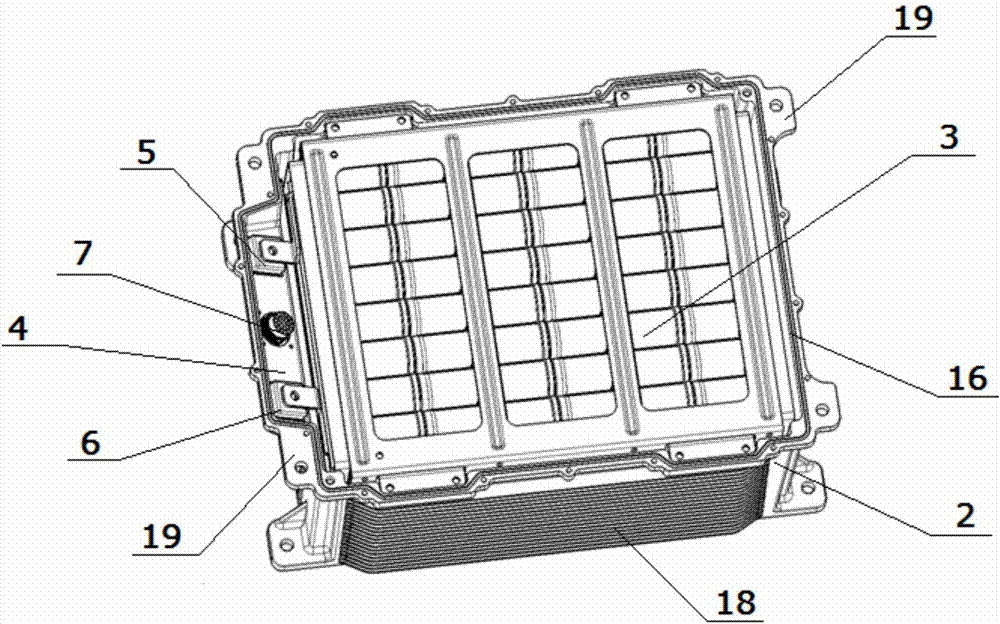

[0025] An oil-cooled battery pack, such as figure 1 , figure 2 As shown, including the upper cover 1, the box body 2 and the battery pack module 3, such as Figure 5 As shown, the upper end of one end of the box body 2 is provided with a functional interface cavity 4 protruding outward, the bottom of the functional interface cavity 4 is inclined upward by 30 degrees, and the bottom of the functional interface cavity 4 is provided with a positive output terminal 5, a negative output terminal 6 and The communication connection terminal 7 is provided with an insulating sleeve (the insulating sleeve is not shown in the figure) between the positive output terminal 5, the negative output terminal 6, the communication connection terminal 7 and the functional interface cavity 4 on the box body 2, and epoxy resin glue is used Glue and connect each terminal and the insulating sleeve, the insulating sleeve and the functional interface cavity together. There are heat sinks 18 on both si...

Embodiment 2

[0027] An oil-cooled battery pack, the structure of which is similar to the oil-cooled battery pack in Embodiment 1, the difference is that: the bottom of the functional interface cavity is inclined upward at an angle of 20 degrees, and the communication connection set on the box body The number of terminals is two.

Embodiment 3

[0029] An oil-cooled battery pack, the structure of which is similar to the oil-cooled battery pack in Embodiment 1, the difference is that: the bottom of the functional interface cavity is inclined upward at an angle of 40 degrees.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com