Stereo multilayer and multipurposebean curd stick making machine

A bean curd machine, three-dimensional technology, applied in the field of three-dimensional multi-layer multi-purpose bean curd machine, can solve the problems that are difficult to meet modern large-scale, multi-variety production, pulp skin quality and formation speed, single production products, etc. The effect of reducing labor costs, reducing energy consumption, and improving equipment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

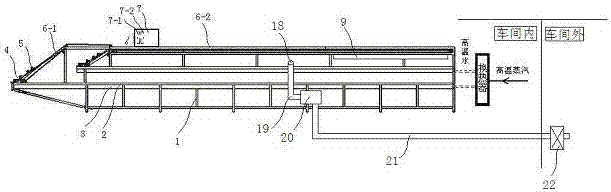

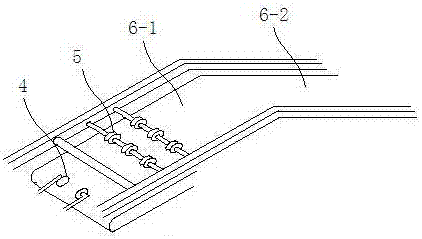

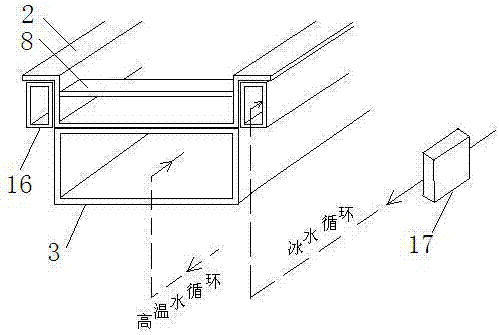

[0036] like figure 1 , 2 , 3, and 4, this embodiment includes a lower layer of soybean milk tank 2 and an upper layer of soybean milk tank 11 fixed on the frame 1, the bottom of each layer of soybean milk tank has a heating system, and the end of each layer of soybean milk tank is connected with a corresponding conveyor The conveyor belt of the pulp skin, the conveyor belt includes a conveyor belt inclined section 6-1 at the front and a conveyor belt horizontal section 6-2 at the rear, the conveyor belt connecting the lower floor soybean milk tank is located outside the conveyor belt connecting the upper floor soybean milk tank The inner conveyor belt is made of nylon breathable material with gaps or seamless airtight material, and the outer conveyor belt is made of nylon breathable material with gaps. The frame is also fixed above the outermost conveyor belt to realize the alignment of each layer. A hot air blower 7 for pre-drying products on the conveyor belt.

[0037] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com