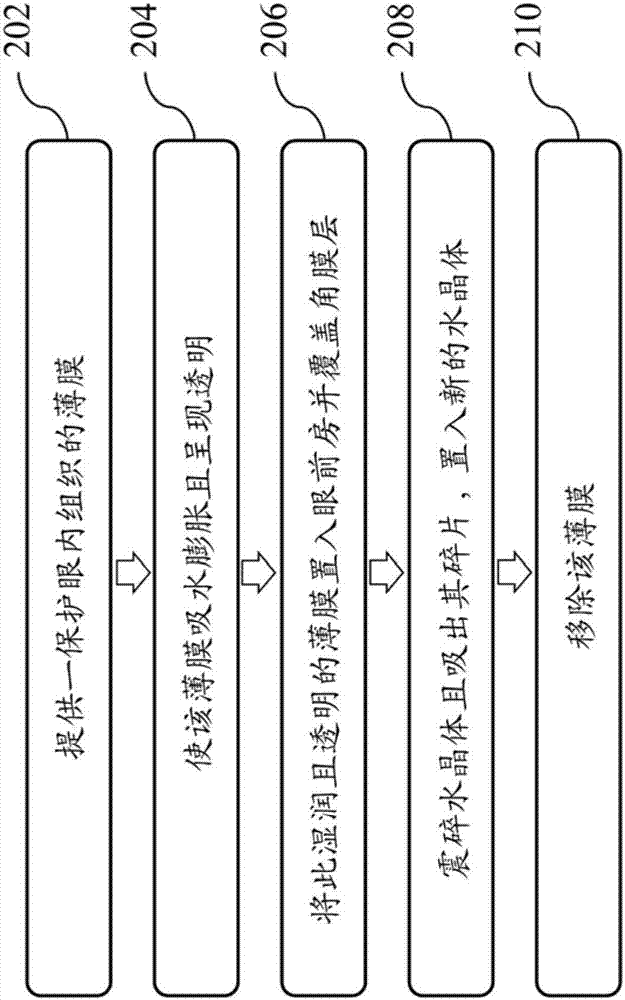

Membrane for protecting intraocular tissues and the protection methods used thereof

A film and transparent film technology, applied in tissue regeneration, application, ophthalmic surgery, etc., can solve the problems of insufficient protection and compartmentalization, difficult to determine the location, unable to form a barrier plane, etc. The effect of fitting, improving elasticity and curvature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

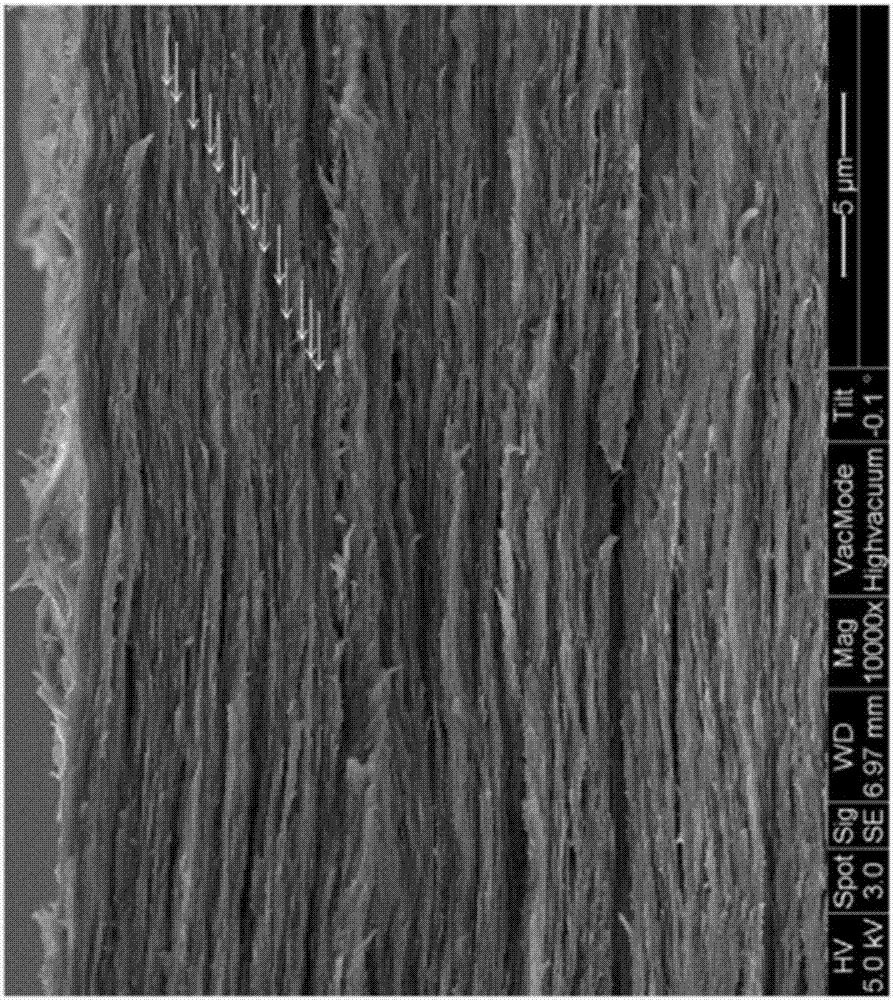

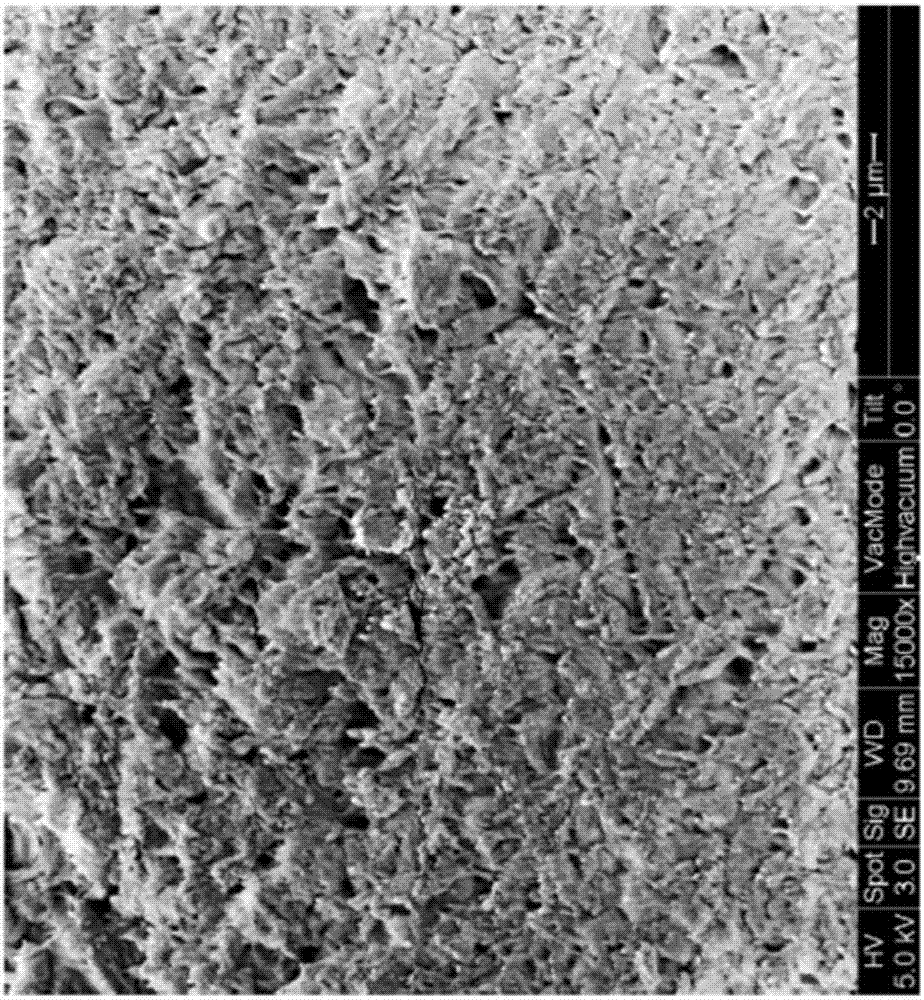

[0048] First, 0.5 g of collagen (fibrous, about 15 mm in length) was added to the reaction bottle, and 100 mL of an aqueous solution with a pH of less than 5 was added to the reaction bottle to disperse the collagen. Next, after stirring until the collagen is completely dispersed in water, the resulting solution is poured into a mold, and placed at room temperature for air-drying. Then, the resulting film can be directly cross-linked and cut into a circle with a diameter of 6-16mm to obtain the film (I); on the other hand, the film can absorb water and cover it on a mold to make it dry and have a arc-shaped curved surface, that is, an arc-shaped curved surface with a radius of curvature of 6-8 mm, and then cross-link the film with the arc-shaped curved surface and cut it into a circle with a diameter of 6-16 mm to obtain a film (I'); The cross-linking reaction was carried out by placing the film in a chamber with saturated vapor of formaldehyde gas for one hour.

Embodiment 2

[0050] First, 0.5 g of collagen (fibrous, about 15 mm in length) was added to the reaction bottle, and 100 mL of an aqueous solution with a pH of less than 5 was added to the reaction bottle to disperse the collagen. Next, after stirring until the collagen is completely dispersed in water, the resulting solution is poured into a mold, and placed at room temperature for air-drying. Then, one can directly cross-link the obtained film and cut it into a circle with a diameter of 6-16mm to obtain the film (II); another can cover the film on a mold after absorbing water, so that it has a arc-shaped surface, that is, an arc-shaped surface with a radius of curvature of 6-8mm, and then cross-link the film with the arc-shaped surface and cut it into a circle with a diameter of 6-16mm to obtain a film (II'); The contact method is to place the film in a cavity and irradiate ultraviolet light for one hour to carry out the crosslinking reaction, wherein the ultraviolet light has a wavelengt...

Embodiment 3

[0052] First, 0.5 g of polyvinyl alcohol (polyvinyl alcohol, PVA; molecular weight about 30,000-50,000) was added to the reaction flask, and 100 mL of pure water was added. After heating and stirring until the polyvinyl alcohol is completely dispersed, an aqueous solution of polyvinyl alcohol is obtained. Next, the aqueous solution of polyvinyl alcohol was titrated with aqueous hydrochloric acid (concentration: 6N), so that the pH of the aqueous solution of polyvinyl alcohol was less than about 3. Next, 0.5 g of collagen (in the form of fibrous fibers with a length of about 15 mm) was added into the reaction bottle, and stirred until the collagen was completely dispersed. Then, the obtained solution was poured into a mold, and placed at room temperature for air-drying. Then, one can directly cross-link the obtained film and cut it into a circle with a diameter of 6-16mm to obtain the film (III); another can cover the film on a mold after absorbing water, so that it has a arc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com