Ozone adding device

A technology of adding devices and ozone, applied in the field of packaging, can solve the problems of increased processing costs, inaccurate control, and very high requirements for bromate control content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

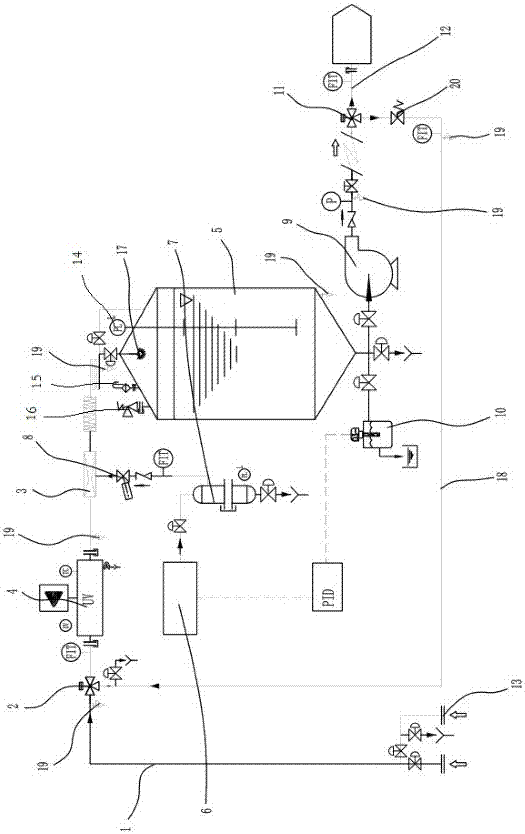

[0009] An ozone adding device, such as figure 2 As shown, it includes a water inlet pipe 1, the water inlet pipe 1 is connected to the first proportional valve 2, the first proportional valve 2 is connected to the air-water mixer 3 through pipelines, and the connection between the first proportional valve 2 and the air-water mixer 3 The pipeline is provided with an ultraviolet lamp 4, and the gas-water mixer 3 communicates with the inner cavity of the oxidation tower 5 through the pipeline, and also includes an ozone generator 6, and the ozone generator 6 communicates with the anti-reflux tank 7 pipelines, The anti-reflux tank 7 is connected with the pipeline of the flow regulating valve 8, the pipeline of the flow regulating valve 8 is connected with the gas-water mixer 3, and the lower part of the oxidation tower 5 is connected with the water pump 9 and the online ozone detection device 10 respectively through the pipeline. The water pump 9 is connected to the pipeline of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com