Method for treating biological hanging films with high-alkali type saline-alkali water

A technology for biological treatment and saline-alkali water, applied in the field of water treatment, can solve the problems of long film hanging time and easily damaged biofilm, and achieve the effect of increasing the nitrosation rate and accelerating mass transfer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

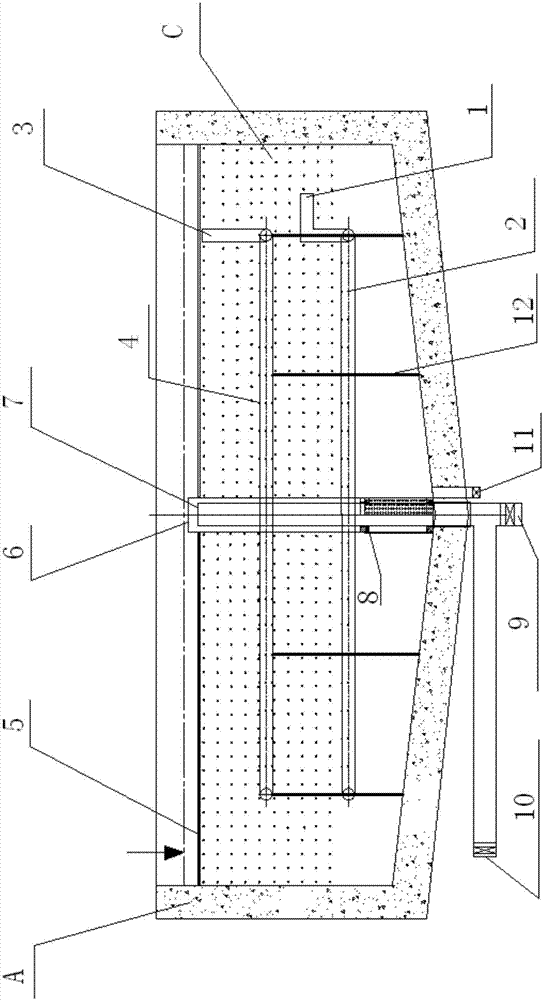

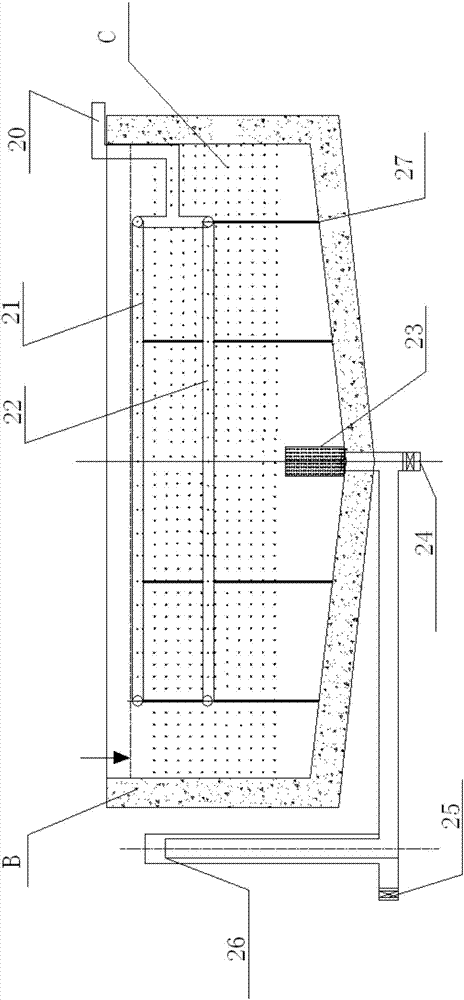

[0017] Specific embodiment one: the method for the high-alkaline saline-alkali water biological treatment of the present embodiment to form a film is realized according to the following steps:

[0018] 1. The biofilm culture system consists of a fixed biological bed culture pool A and a mobile biological bed culture pool B. Microbial strains of nitrifying bacteria and denitrifying bacteria are inoculated on the buoyant filter material carrier C, and then the buoyant bacteria with microbial strains are inoculated. The permanent filter material carrier C is filled in the fixed biological bed culture pool A and the mobile biological bed culture pool B respectively;

[0019] 2. A stainless steel mesh 5 is laid on the pool surface of the fixed biological bed cultivation pool A, and an annular recoil pipe 4 is arranged in the middle of the fixed biological bed cultivation pond A, and the annular recoil pipe 4 is connected with the fixed bed recoil inlet pipe 3 Tong, on the outer wal...

specific Embodiment approach 2

[0025] Embodiment 2: This embodiment is different from Embodiment 1 in that the pool body material of the fixed biological bed cultivation pool A and the mobile biological bed cultivation pool B described in step 1 is reinforced concrete or glass fiber reinforced plastic. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0026] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that the buoyant filter material carrier C is a PP plastic ball. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com