Method for treating lignite quality-improving waste water through aerobic cometabolism

A technology of co-metabolism and coal chemical wastewater, applied in the direction of aerobic process treatment, mining wastewater treatment, sustainable biological treatment, etc., can solve the problem of limited microbial species, increased difficulty and load of advanced treatment, and efficiency of lignite upgrading wastewater biological treatment process Low-level problems, to achieve the effect of improving treatment efficiency and biological treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

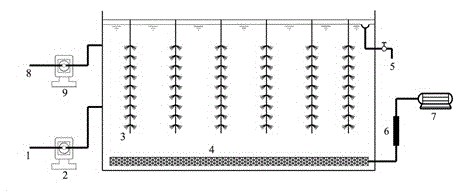

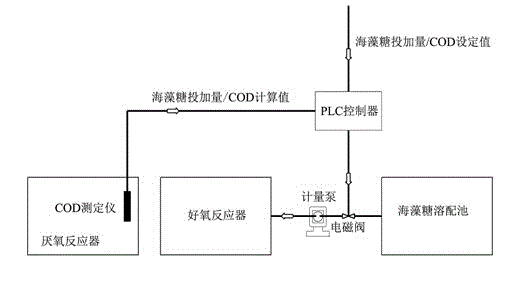

[0010] Specific implementation mode one: this implementation mode is the method for anaerobic co-metabolism treatment of lignite upgrading wastewater, which is specifically completed according to the following steps:

[0011] ①Select lignite upgrading wastewater, which is collected from the lignite upgrading process, and after cooling and sedimentation in the intermediate sedimentation tank, the following process is used: adding demulsifier and flocculant, after demulsification, coagulation, and sedimentation treatment The final supernatant water is lifted to the anaerobic reactor by a peristaltic pump for anaerobic hydrolysis and acidification treatment, and the effluent from the anaerobic reactor is the lignite upgrading wastewater to be treated. The water quality is as follows: COD concentration 950~1200mg / L, BOD 5 The concentration is 350~400mg / L, the total phenol concentration is 70~90mg / L, the ammonia nitrogen concentration is 55~70mg / L, and the total phosphorus concentr...

specific Embodiment approach 2

[0019] Specific embodiment two: the difference between this embodiment and specific embodiment one is that step 3. in, the COD volume load of aerobic reactor is 1.2 kgCOD / (m 3 ·d) or 1.5kgCOD / (m 3 d), the hydraulic retention time is 20h or 24h, and the others are the same as the specific embodiment one.

specific Embodiment approach 3

[0020] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that in step 4., the initial inoculation sludge dosage in the aerobic reactor is 5g / L, other and specific embodiment one or two same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume load | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com