Process and equipment for treating and reusing waste water from lead-zinc ore beneficiation

A mineral processing wastewater and treatment process technology, applied in mining wastewater treatment, water/sewage multi-stage treatment, oxidized water/sewage treatment, etc., can solve the problem that lead-zinc sulfide mineral processing wastewater is rarely used, and it is impossible to remove organic matter in lead-zinc wastewater, Difficulty in reusing lead-zinc beneficiation wastewater and other issues to achieve the effect of eliminating negative impacts, strengthening biological treatment effects, and solving environmental risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

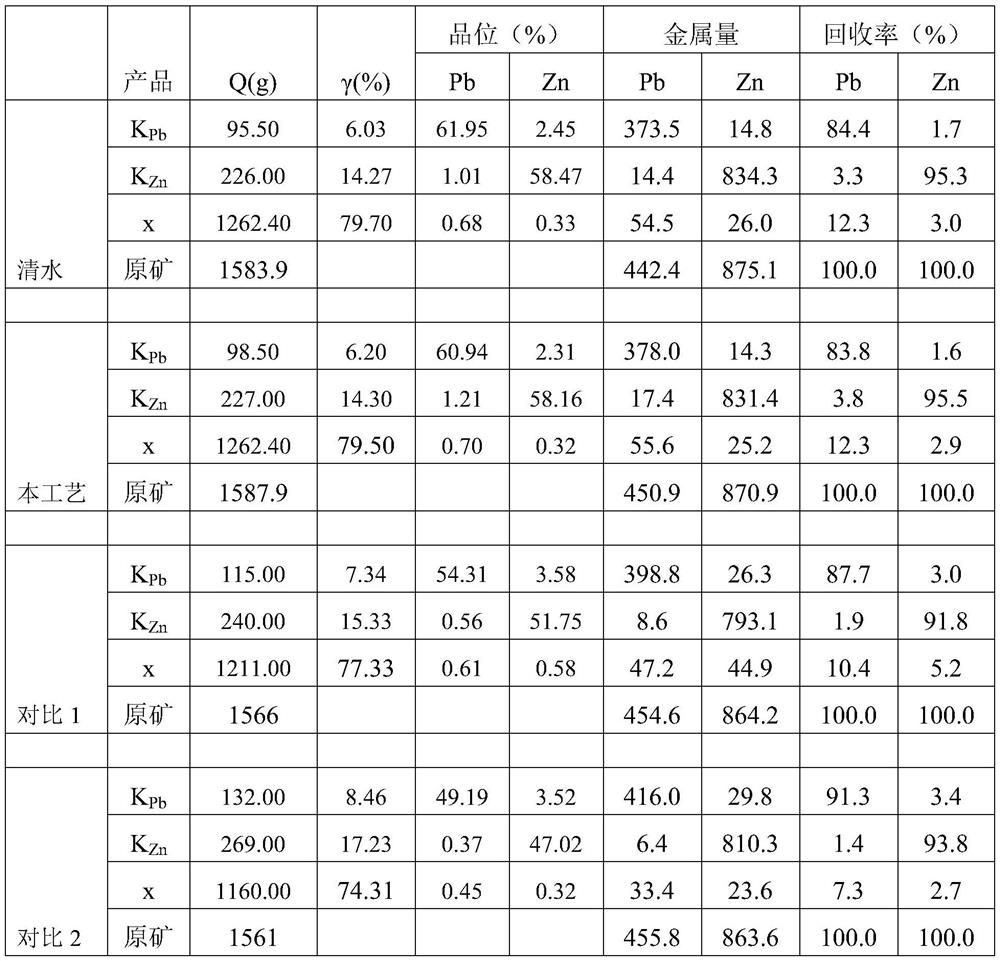

[0050] The mineral processing wastewater of a large-scale lead-zinc mine in northern Guangdong is selected. The sources of wastewater are divided into three sources: lead-zinc mineral processing wastewater (including concentrate overflow), sulfur concentrate overflow water, and sulfur tail water (including trench water). The wastewater ratio is 70% :14:16, see Table 1 for wastewater quality analysis, the test water volume is 60L / d, and the operation mode is continuous operation.

[0051] Table 1 Analysis of wastewater quality (mg / L, except pH)

[0052] pH Ca Fe Cu Zn Pb CODcr NH 3 -N

TP SS 12.3 820 3.85 2.04 0.85 1.73 418 23.4 1.50 371

[0053] The technical process of the embodiment of the present invention 1 can be specifically expressed as follows:

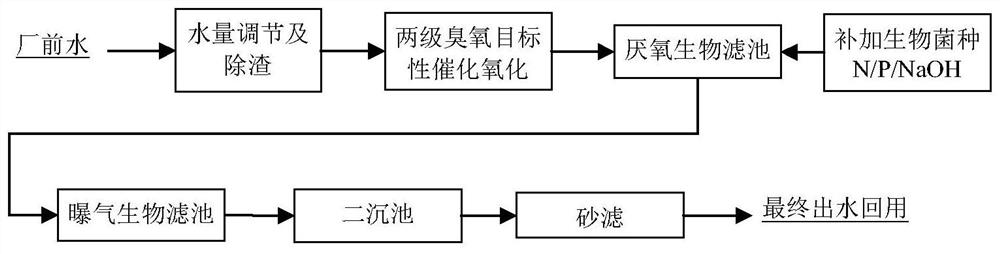

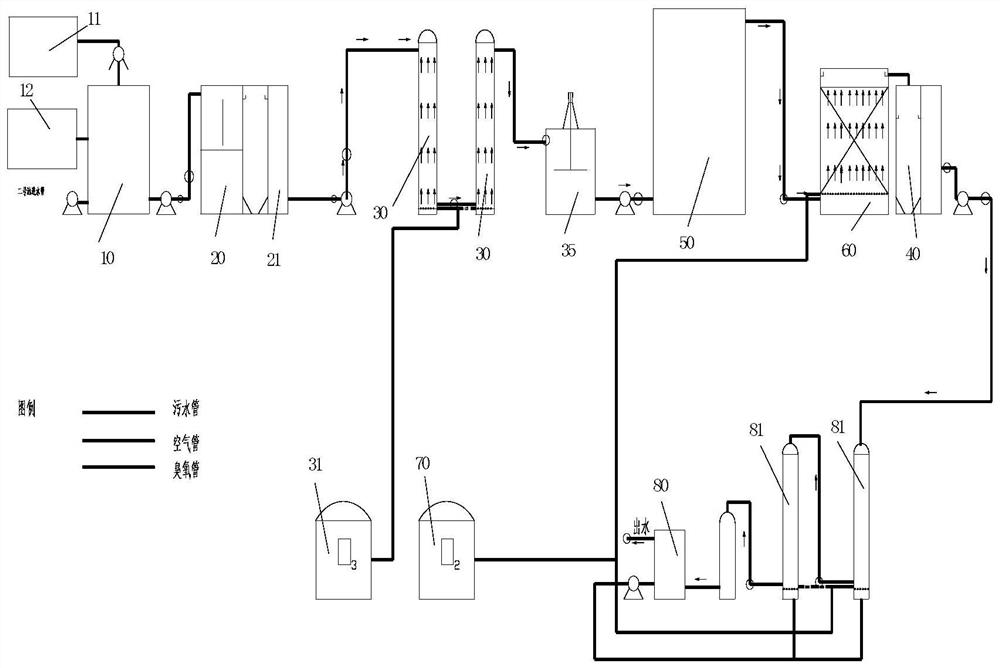

[0054] 1) After the wastewater is collected and treated by primary sedimentation, it undergoes two-stage ozone oxidation to eliminate the reducing substances in the mineral proc...

Embodiment 2

[0070] The beneficiation wastewater of a large-scale lead-zinc mine in Tieling area, Liaoning Province was selected. The source of the wastewater is lead-zinc beneficiation wastewater. The water quality analysis of the wastewater is shown in Table 4. The test water volume is 60L / d, and the operation mode is continuous operation.

[0071] Table 4 Waste water quality analysis (mg / L, except pH)

[0072] pH Ca Fe Cu Zn Pb CODcr NH 3 -N

TP SS 11.4 460 0.55 1.02 1.20 0.85 368 50.1 0.88 519

[0073] See Table 5 for the effluent water quality after the reaction according to this technological process and the comparative 1 and comparative 2 processes.

[0074] Table 5 Analysis of effluent water quality (mg / L, except pH)

[0075] out of water pH Ca Fe Cu Zn Pb CODcr NH3-N TP SS This craft 7.05 317 0.52 0.68 0.44 0.71 28.5 25.3 0.31 31.6 Contrast 1 6.12 385 0.43 0.79 0.65 0.49 44.1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com