A combined cationic collector for reverse flotation desiliconization of hematite ore

A cationic collector, reverse flotation desiliconization technology, applied in flotation, solid separation, etc., can solve the problems of high energy consumption, large dosage of chemicals, poor fluidity and selectivity, etc., and achieve simple preparation process and low equipment investment Less, easy to use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

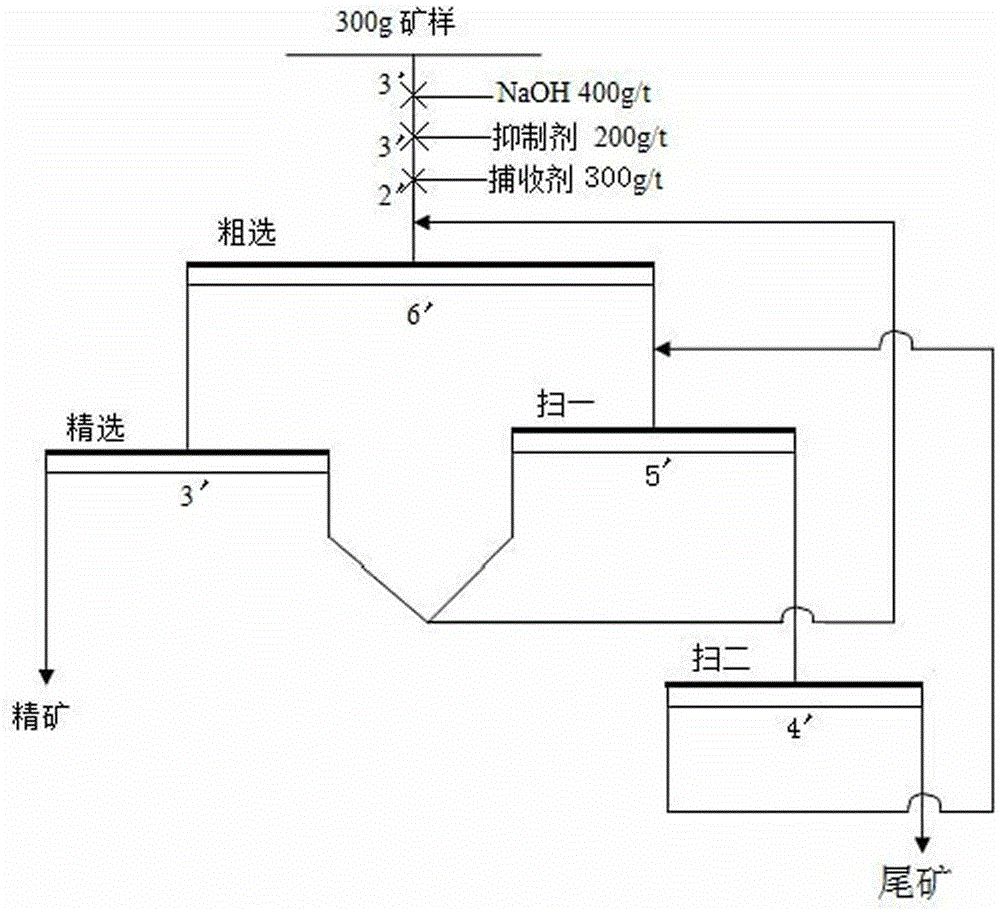

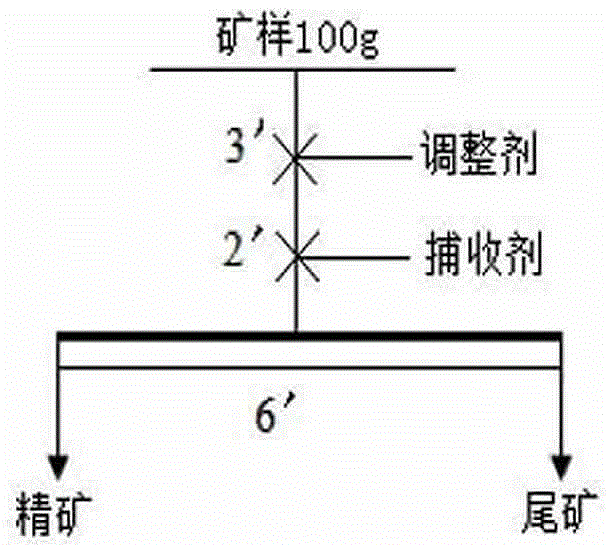

[0018] Example 1: Mix hematite pure minerals (TFe68.88%) and quartz pure minerals at a mass ratio of 60:40, and perform flotation according to the following reagent system and process conditions: Cationic collectors for reverse flotation of hematite ore Medium N-dodecyl ethylenediamine: acetic acid: polyethylene glycol = 100:50:100, the dosage of cationic collector for reverse flotation of hematite ore is 200g / t, and the dosage of regulator cornstarch is 150g / t.

[0019] Get mixed ore 100g and add in the flotation machine, the pulp concentration is 40%, according to figure 1 Flotation is carried out in the process shown, and the iron concentrate with an iron grade of 57.23% and an iron recovery rate of 90.64% can be obtained, and the iron grade of the tailings is 10.70%.

example 2

[0020] Example 2: Mix hematite pure minerals (TFe68.88%) and quartz pure minerals at a mass ratio of 60:40, and perform flotation according to the following reagent system and process conditions: Cationic collectors for reverse flotation of hematite ore In N-dodecyl ethylenediamine: acetic acid: n-butanol=100:70:100, the amount of cationic collector for reverse flotation of hematite ore is 200g / t, and the amount of regulator cornstarch is 100g / t t.

[0021] Get mixed ore 100g and add in the flotation machine, the pulp concentration is 40%, according to figure 1 Flotation is carried out in the process shown, and the iron concentrate with an iron grade of 57.44% and an iron recovery rate of 90.02% can be obtained, and the iron grade of the tailings is 11.71%.

example 3

[0022] Example 3: Mix hematite pure minerals (TFe68.88%) and quartz pure minerals in a mass ratio of 60:40, and perform flotation according to the following reagent system and process conditions: N-dodecyl ethyl alcohol in combined cationic collectors Diamine: acetic acid: n-hexanol = 100:60:100, the dosage of cationic combined collector is 200g / t, and the dosage of regulator cornstarch is 100g / t.

[0023] Get mixed ore 100g and add in the flotation machine, the pulp concentration is 40%, according to figure 1 Flotation is carried out in the process shown, and the iron concentrate with an iron grade of 56.23% and an iron recovery rate of 91.58% can be obtained, and the iron grade of the tailings is 10.66%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com