Process for substep treatment and quality-based utilization of lead-zinc sulfide ore mine wastewater

A technology for mine wastewater and lead and zinc sulfide, which is applied in mining wastewater treatment, water/sewage treatment, water/sewage multi-stage treatment, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

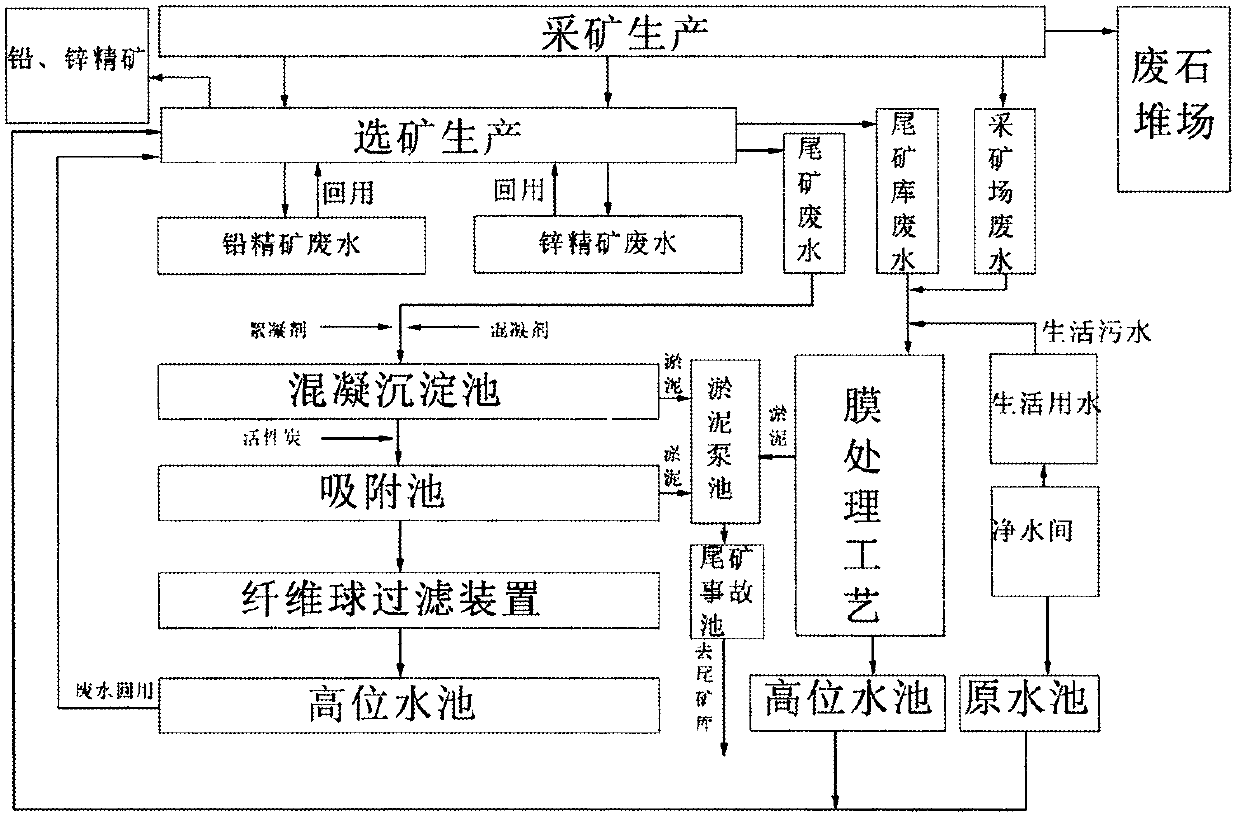

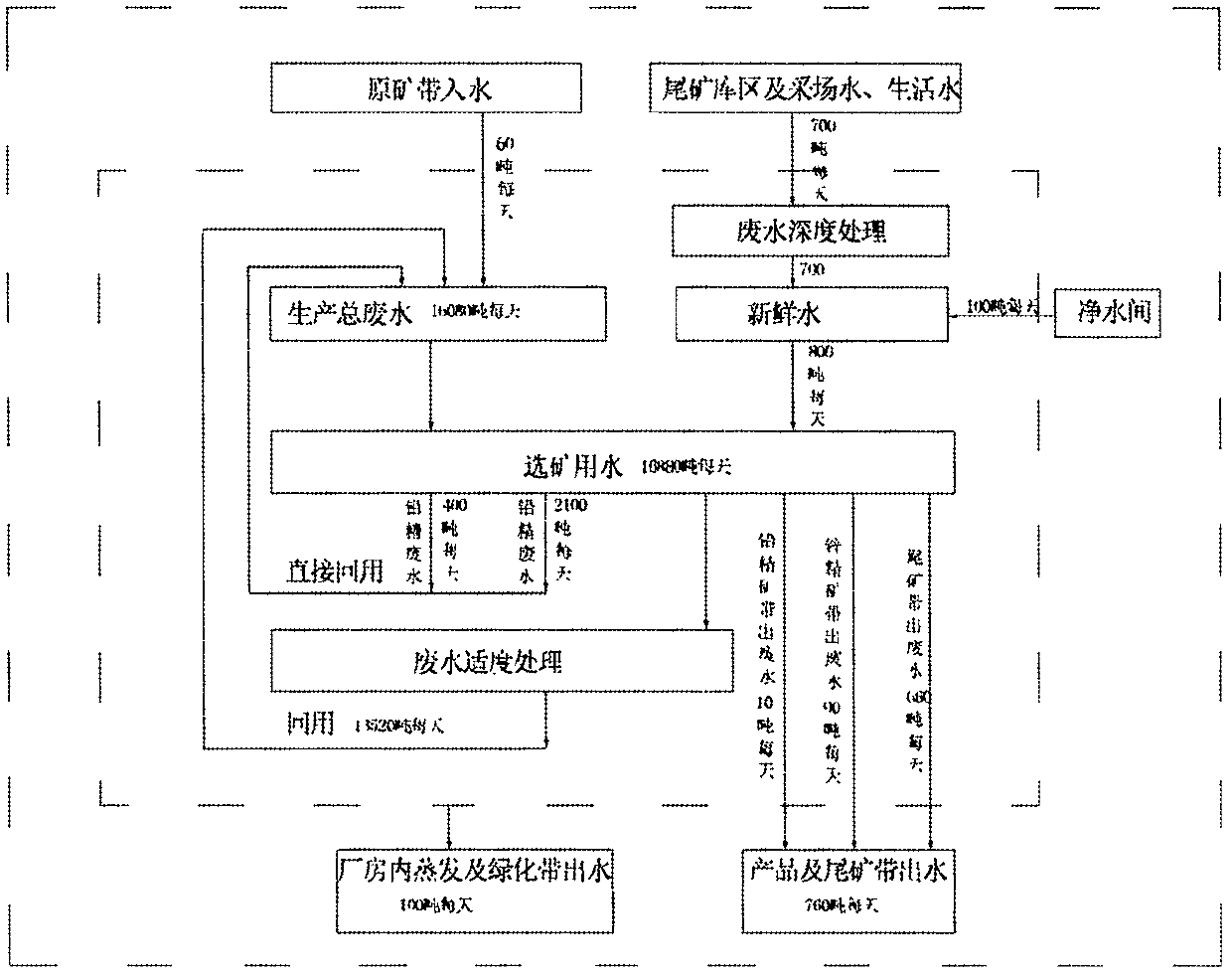

Method used

Image

Examples

Embodiment 1

[0018] Inner Mongolia Zhalantun Guosen Mining Co., Ltd.’s lead-zinc-silver polymetallic mine, the basic process used in on-site beneficiation production is as follows: raw ore grinding to -200 mesh accounts for about 70%, and lead and zinc are used in sequence under high alkalinity conditions. Flotation process, the lead flotation process is one coarse, three sweeping and four fine, the medium ore products are returned in sequence, and the lead flotation coarse concentrate is regrinded when processing sulfide ore (or when high-grade lead concentrate is required); Lead flotation tailings adopt a process of roughing, cleaning, and cleaning to recover zinc. The flotation lead-zinc concentrates are respectively thickened and dehydrated by ceramics, and then enter the concentrate warehouse for sale. The concentrate overflow water contains a large amount of copper, lead, zinc and other heavy metal ions and flotation reagents.

[0019] If the concentrate overflow water is mixed and ...

Embodiment 2

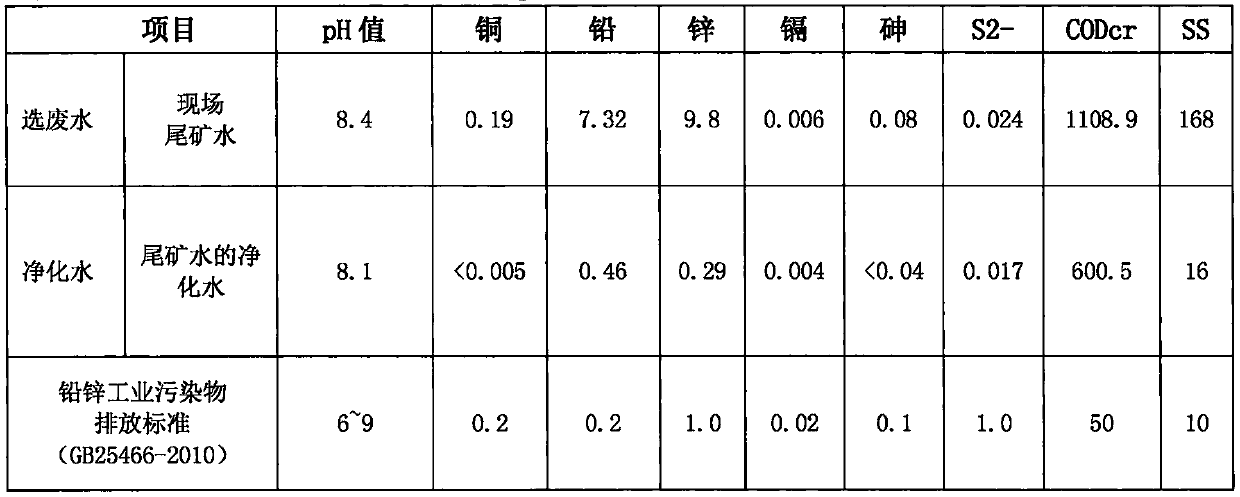

[0024] For the flotation tailings wastewater of lead-zinc-silver polymetallic ore of Inner Mongolia Zhalantun Guosen Mining Co., Ltd., 30g / t of potassium alum and 0.3g / t of anion PAM were added for coagulation reaction and flocculation sedimentation. After 1 After hours of precipitation, heavy metal ions such as copper, lead, zinc, cadmium, and chromium that affect the beneficiation indicators in the tailings wastewater are removed; then 30g / t of coconut shell-type powdered activated carbon is added and removed through a fiber ball filter tower Part of the organic residual chemicals and suspended solids that affect the beneficiation indicators. The comparison results of tailings wastewater quality before and after moderate treatment are shown in Table 1.

[0025] Table 1 Mineral processing wastewater and purified water quality testing results (mg / L)

[0026]

[0027] Most of the moderately treated wastewater is reused in the beneficiation process. It can be seen from Tabl...

Embodiment 3

[0031] Inner Mongolia Zhalantun City Guosen Mining Co., Ltd.'s lead-zinc-silver mining is open-pit mining, and the mining area is located in the Greater Khingan Mountains area. The water gushing out of the pit is weakly acidic and the heavy metal ions such as lead and zinc are higher than the surface drainage standards, so they cannot be discharged directly.

[0032] The pit water is pumped into a special high-level pool, and then part of it enters the greening water point of the factory area through the pipeline as greening water; part of it enters the tailings reservoir area of the tailings dewatering dry stack, which is used for dust suppression and spraying water in the reservoir area.

[0033] Finally, after adding 200g / t of soda ash and 1 hour of precipitation, the redundant moderately treated tailings wastewater and pit water are then subjected to coarse, medium and fine three-layer sand filtration and microfiltration (the filter element is made of PP cotton or activate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com