Self-draining string type underreamed anchor supporting structure and construction method

A technology of bolt support and self-drainage, which is applied in basic structure engineering, excavation, construction, etc., can solve problems such as increased construction difficulty and investment, complicated manufacturing process, and slope soil collapse, so as to improve mechanical properties, The manufacturing process is simple and the effect of reducing the water content of the soil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solutions of the present invention will be further described below in conjunction with specific embodiments.

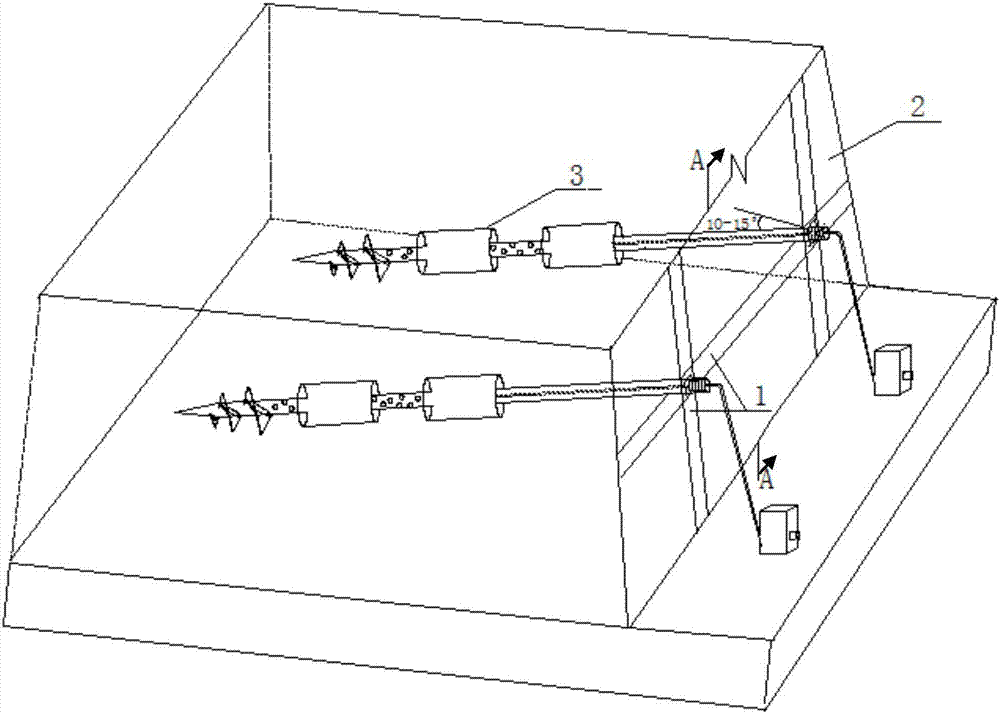

[0032] See attached figure 1 , the self-draining series expansion bolt support structure, including the self-drainage series expansion anchor 3, the self-drainage series expansion anchor 3 is anchored into the deep foundation pit, and the self-drainage series expansion anchor A lattice frame 1 and a retaining plate 2 are arranged at the end of the rod 3 to form a deep foundation pit support structure;

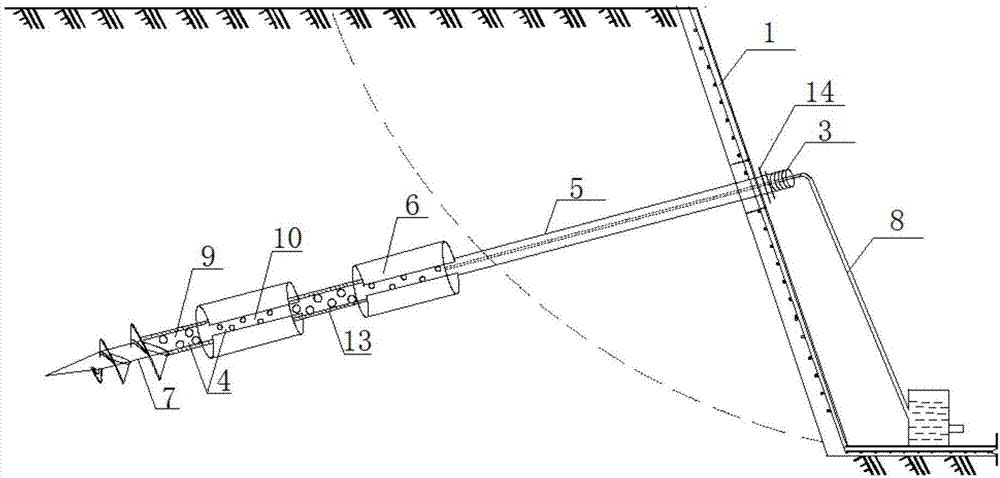

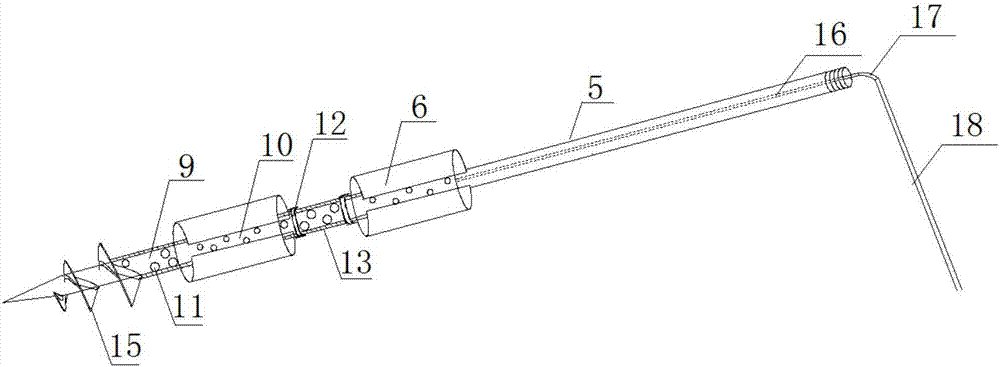

[0033] See attached Figure 2-3 , the self-drainage series expansion anchor rod 3 includes a variable diameter water filter steel pipe 4, a hollow steel pipe 5, a water absorption expansion ring 6, an auger tip 7 and a siphon 8,

[0034]The front end of the self-drainage series expansion anchor rod 3 is an auger tip 7, and the auger tip 7, the variable-diameter water filter steel pipe 4 and the hollow steel pipe 5 are sequentially connected by th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com