A Device for Preventing Reactor Bombing Rod Accidents

A technology for reactors and sticks, which is applied in the fields of reactors, nuclear reaction control, nuclear power generation, etc., can solve the problems of not being able to fully guarantee that the pressure cover is not ruptured and damaged, without the safety facilities for sticks, and increasing the reactivity, so as to achieve automation and safety. High, reduce the range of changes, and improve the effect of reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

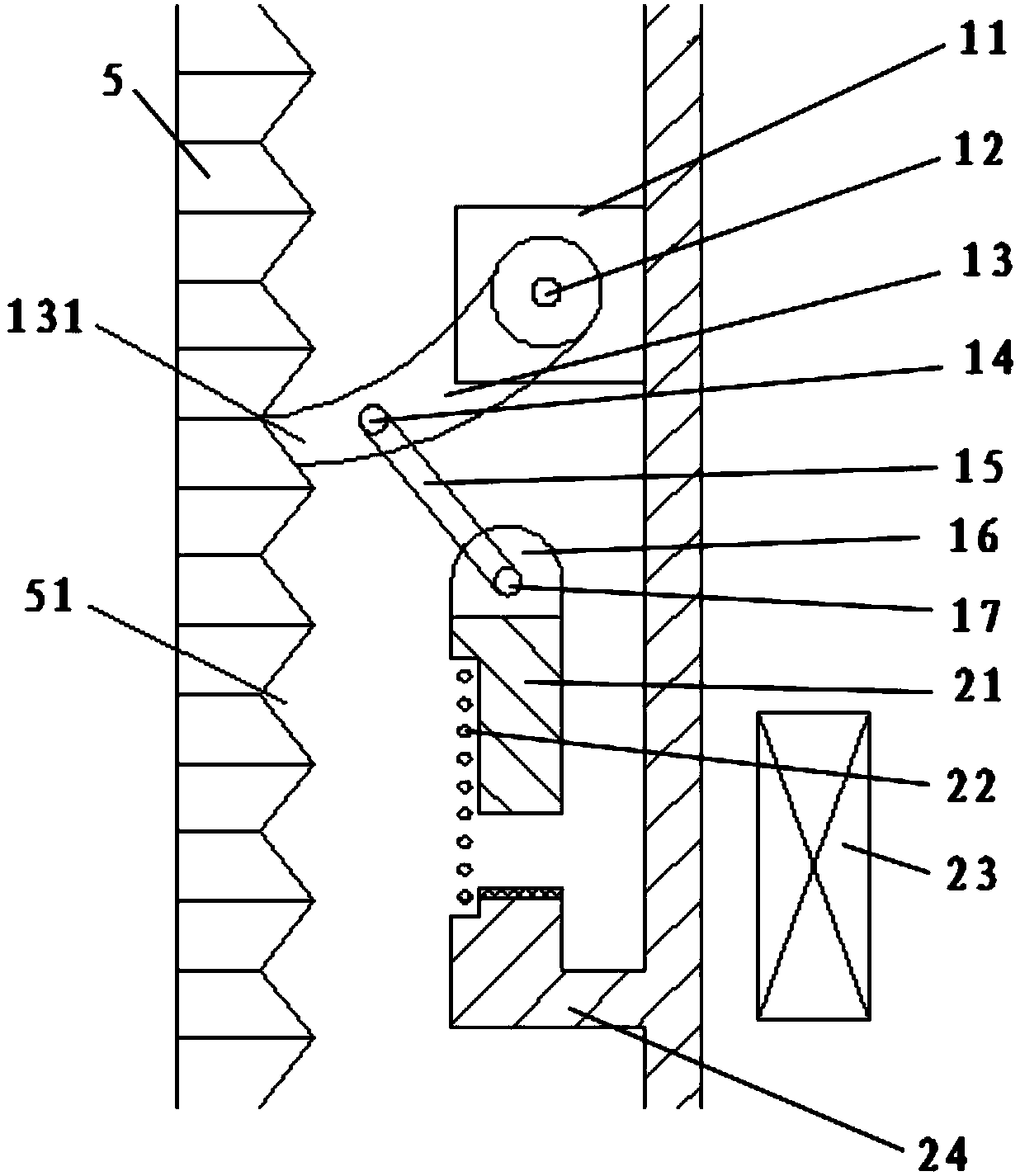

[0057] The present invention will be further described in detail through the drawings and examples below. Through these descriptions, the features and advantages of the present invention will become more apparent.

[0058] The word "exemplary" is used exclusively herein to mean "serving as an example, embodiment, or illustration." Any embodiment described herein as "exemplary" is not necessarily to be construed as superior or better than other embodiments. While various aspects of the embodiments are shown in drawings, the drawings are not necessarily drawn to scale unless specifically indicated.

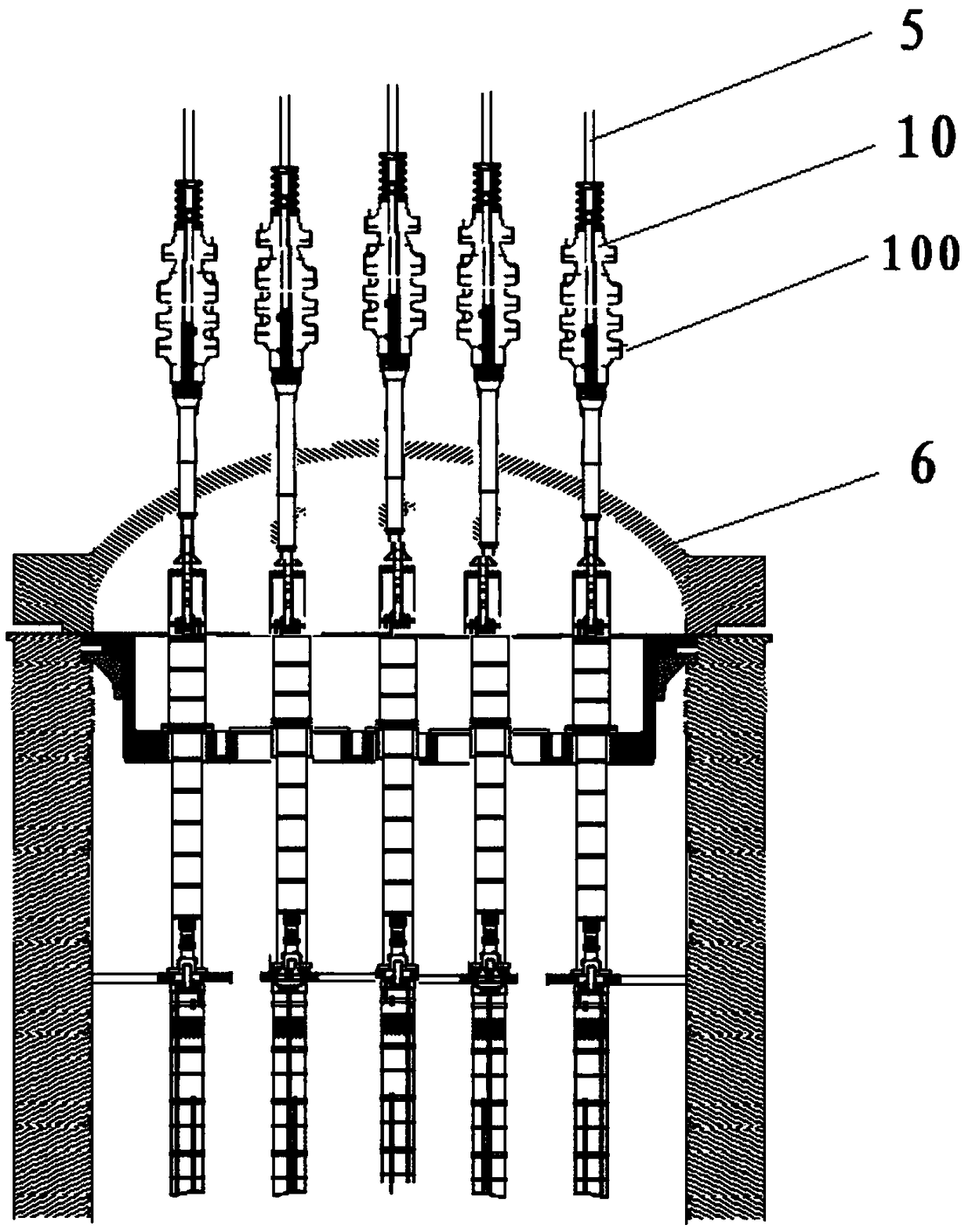

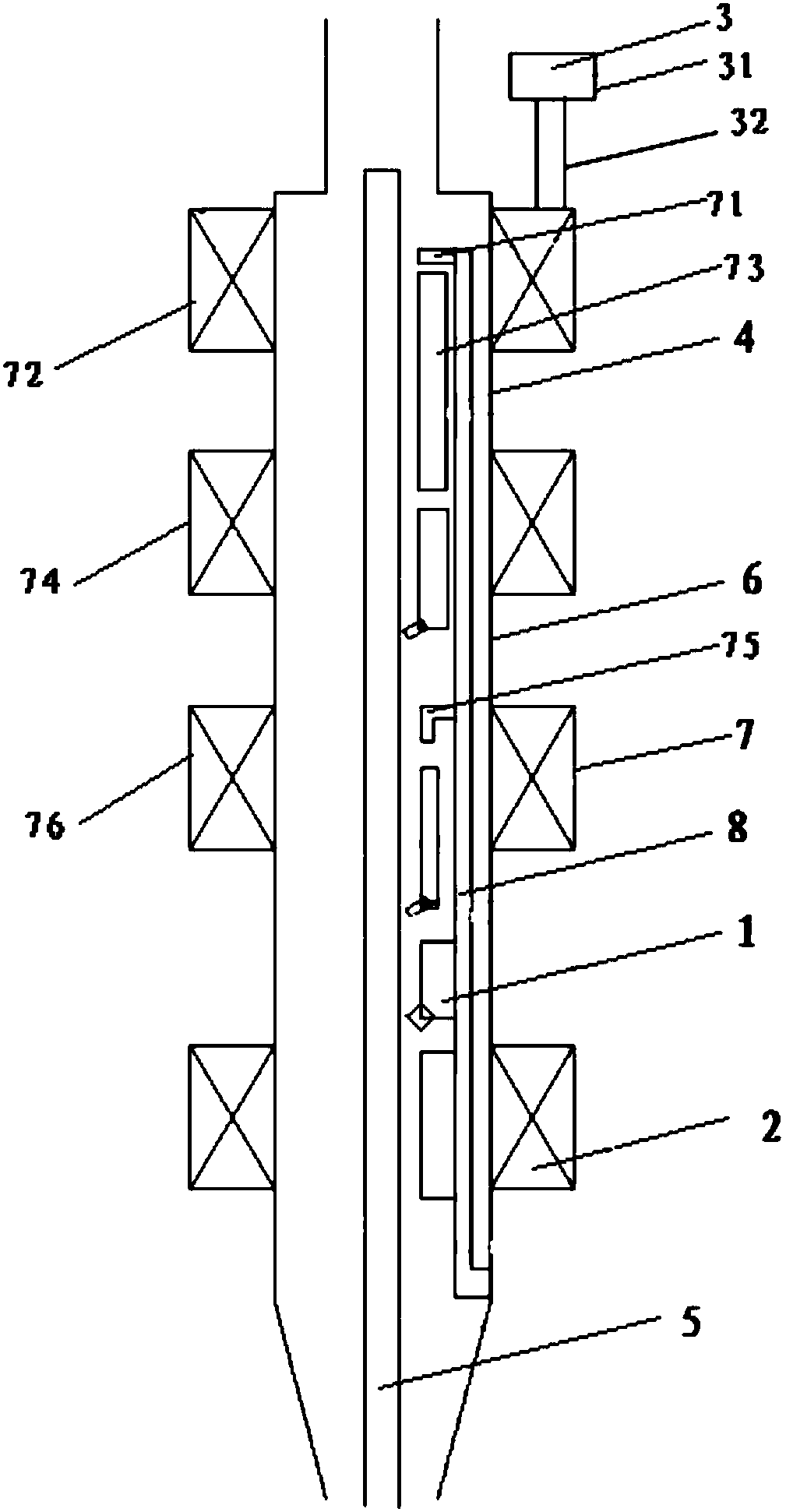

[0059] According to a kind of device that the present invention provides to prevent the reactor from bouncing a rod accident, its relative position with the reactor pressure vessel 6 is as follows: figure 1 As shown, it is located at the external upper end of the reactor pressure vessel 6 and placed at the lower part of the control rod driving mechanism 10 .

[0060] In a preferr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com