A stress-strain assisted pyroelectric composite material and its application

A technology of stress-strain and composite materials, which is applied in the direction of circuits, electrical components, semiconductor devices, etc., can solve the problems of small pyroelectric coefficient, achieve the effect of enhancing the change of electric polarization intensity, improving the pyroelectric coefficient, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

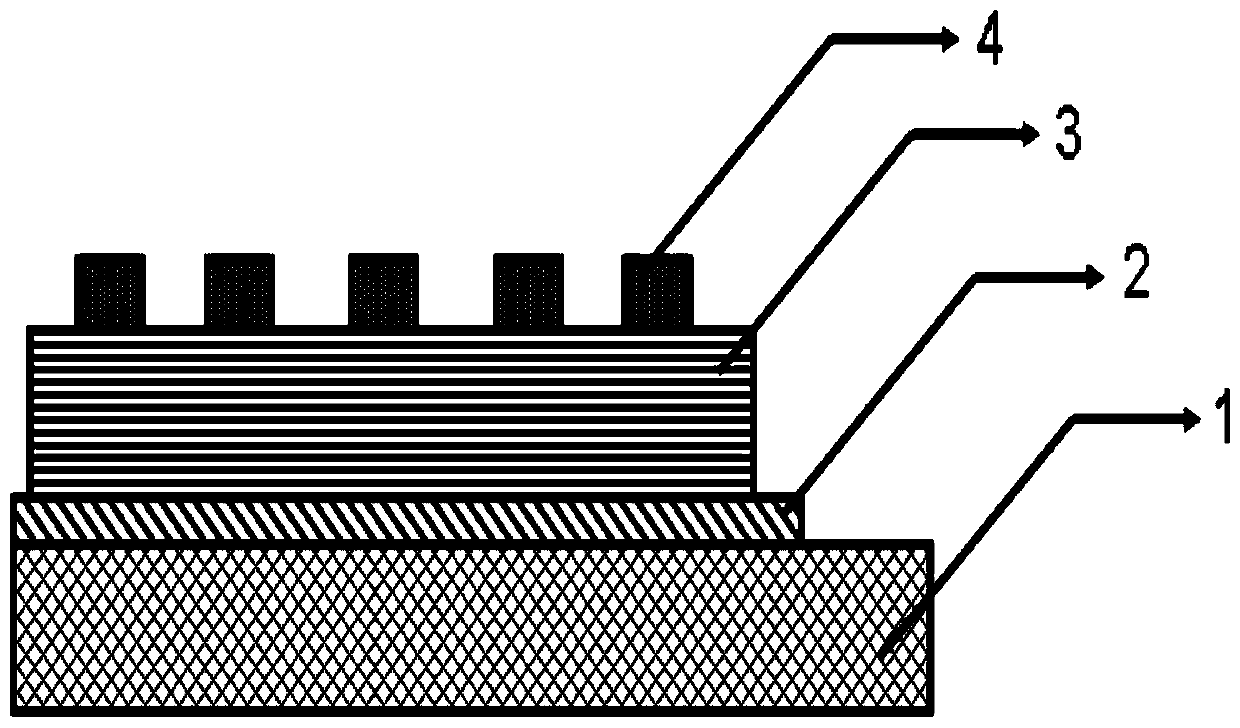

[0034] In this example, if figure 1 As shown, the stress-strain assisted pyroelectric composite material includes a stress-strain application layer 1, a lower conductive layer 2 located on the stress-strain application layer 1, a pyroelectric layer 3 located on the lower conductive layer 2, and a pyroelectric layer located on the Upper conductive layer 4 on layer 3.

[0035] The stress-strain application layer 1 is BaTiO 3 Single crystal, forms substrate support and provides stress-strain application function. The lower conductive layer 2 is SrRuO 3 film. The pyroelectric layer 3 is antiferroelectric Pb(ZrTi)O 3 film. The upper conductive layer 4 is metal Cu.

[0036] BaTiO 3 The single crystal forms the substrate support and provides the stress-strain application function.

[0037] SrO 3The thin film forms the lower conductive layer and has the function of transferring stress and strain, with a thickness of 10-100 nm, which is 16 nm in this embodiment.

[0038] Meta...

Embodiment 2

[0053] In this embodiment, the structure of the stress-strain assisted pyroelectric composite material is basically the same as in Embodiment 1, the difference is that in this embodiment, the pyroelectric layer 3 is antiferroelectric PbHfO 3 film.

[0054] The preparation method of the above-mentioned stress-strain assisted pyroelectric composite material is as follows:

[0055] (1) Antiferroelectric PbHfO 3 Target preparation

[0056] According to the chemical molecular formula, mix appropriate amount of PbO and HfO2 and grind evenly, and pre-fire at 800°C for 2 hours; after pre-burning, grind again, then press into a target, and fire at 1000°C for 2 hours to obtain antiferroelectric PbHfO 3 target.

[0057] (2) Film preparation

[0058] BaTiO 3 The single crystal substrate substrate is placed in a vacuum chamber, heated to 800°C, and then 10Pa oxygen is introduced, and the BaTiO 3 Deposition of SrRuO with a thickness of 16 nm on a single crystal substrate 3 thin film...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pyroelectric coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com