Large-ground-clearance self-propelled plant protection machine with full hydraulic system

A fully hydraulic, plant protection machine technology, applied in the fields of trapping or killing insects, applications, animal husbandry, etc., can solve the problems of single low-stalk crop application, difficult to meet the application operation, vibration and noise, etc. , to achieve the effect of adjustable ground clearance, reasonable structure and good steering performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

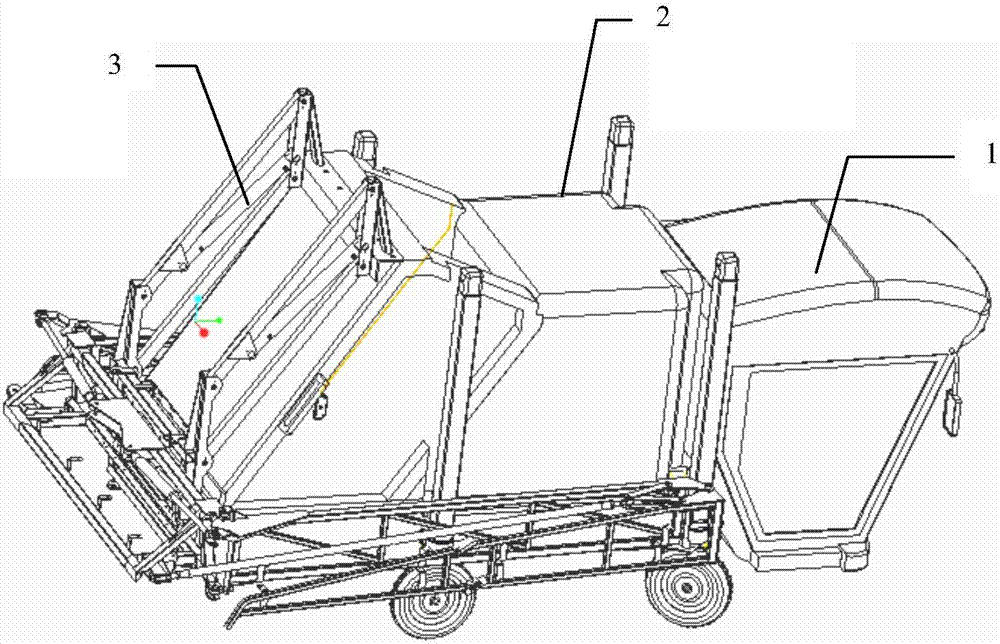

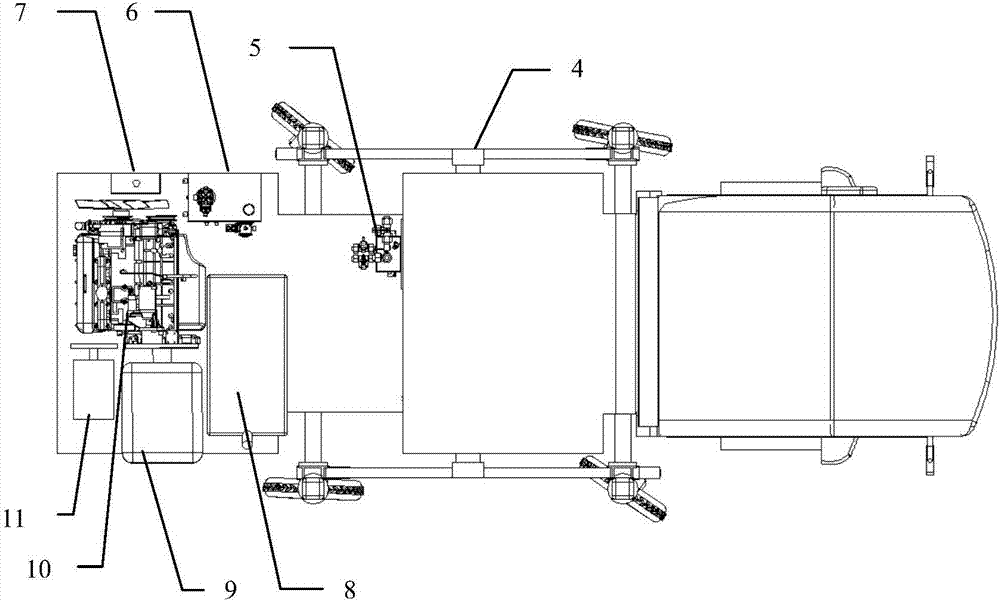

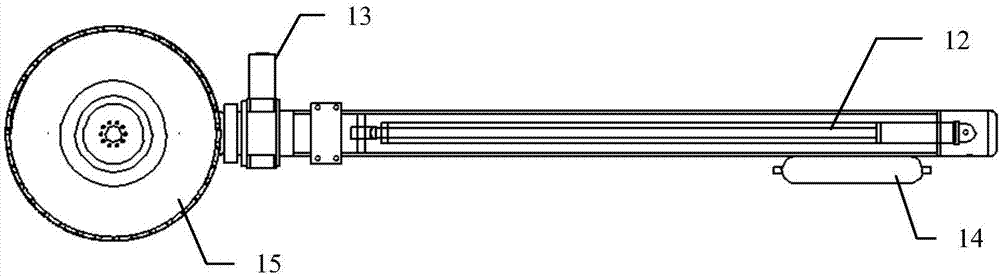

[0018] exist figure 1 and figure 2 In the schematic diagram of the full hydraulic system high ground clearance self-propelled plant protection machine shown, the cab 1 is fixed at one end of the chassis, the medicine box 2 is fixed at the middle of the chassis, and the spray rack assembly 3 is set at the other end of the chassis; the chassis is connected On the wheel frame, the two longitudinal frames in the direction from the cab to the spray rack assembly are square steel, and the two transverse frames connecting the two longitudinal frames are both steel pipes that are divided into two sections, and the steel pipes are covered with sliding sleeves , There is also an intermediate sliding sleeve between the two sliding sleeves. Two width variable driving hydraulic cylinders are arranged in the intermediate sliding sleeve to form a width variable driving mechanism 4. One end of the two width variable driving hydraulic cylinders is connected to the The other ends of the slidi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com