Steel bar connecting method based on alternating and direct current double wire submerged arc

A connection method, AC and DC technology, applied in welding equipment, arc welding equipment, welding/welding/cutting items, etc., can solve the problem of low welding strength, achieve the effects of improving strength, tight connection, and reducing the probability of occurrence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

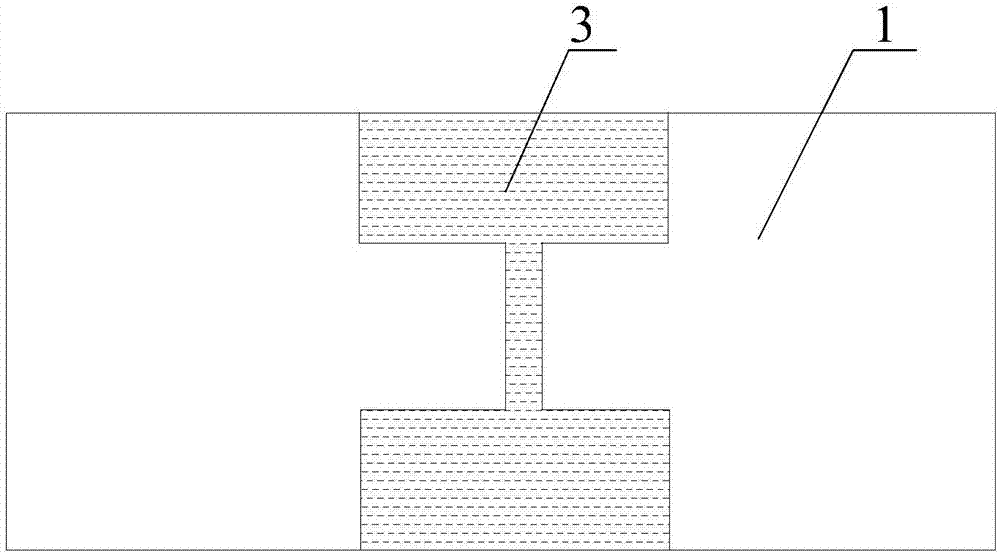

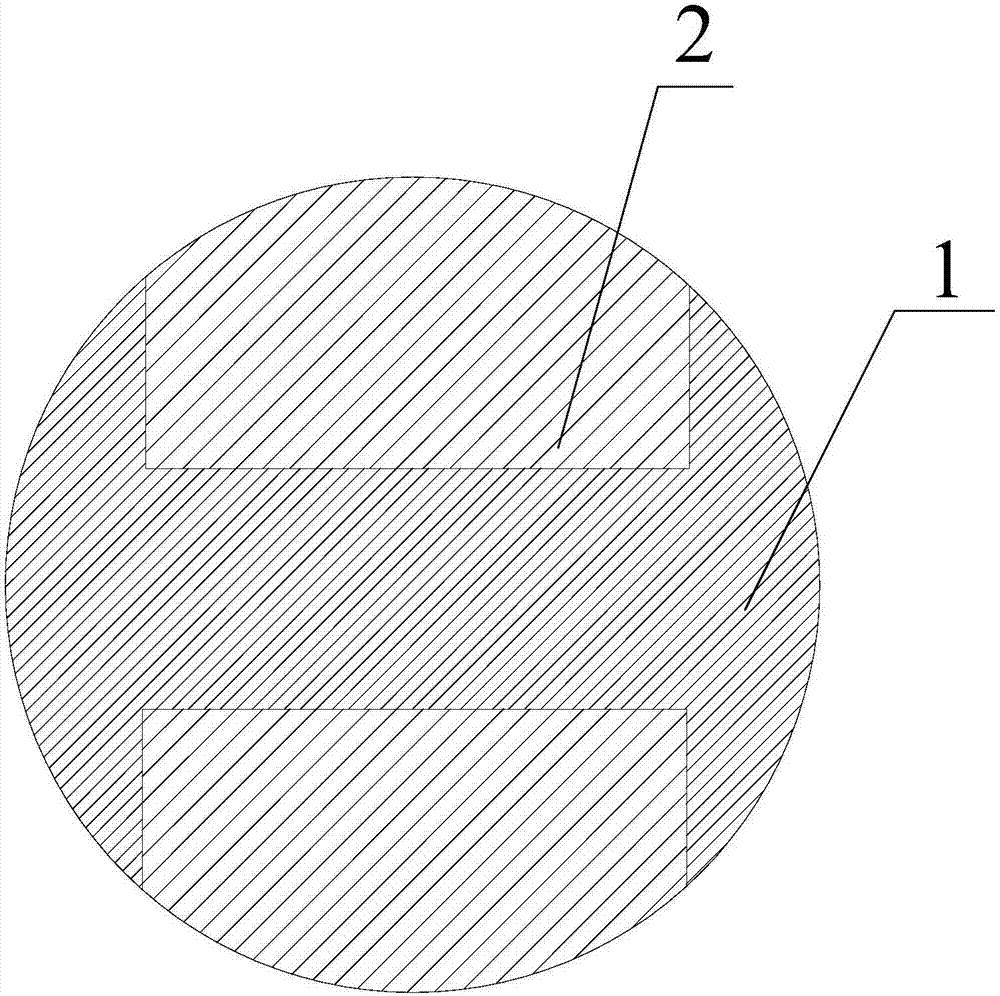

[0022] Such as figure 1 , 2 As shown, the present invention is based on the AC-DC double-wire submerged arc steel bar connection method, comprising the following steps:

[0023] A: prepare two equal-diameter steel bars 1, and open two rectangular grooves 2 on the end face of the steel bar 1, and the rectangular grooves 2 are symmetrical about the central axis of the steel bar 1;

[0024] B: Adjust the two steel bars 1 so that the rectangular grooves 2 of the two steel bars 1 face the same direction, and at the same time make the bottom surface of the rectangular groove 2 on each steel bar 1 vertically upward, and the two steel bars 1 The rectangular groove 2 faces the same direction, and then spot welding and positioning at the center points of the ends of the two steel bars 1, so that the center points of the two steel bars 1 are connected as one, and the distance between the end faces of the two steel bars 1 is 3mm ;

[0025] C: Preheat the two rectangular grooves 2, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com