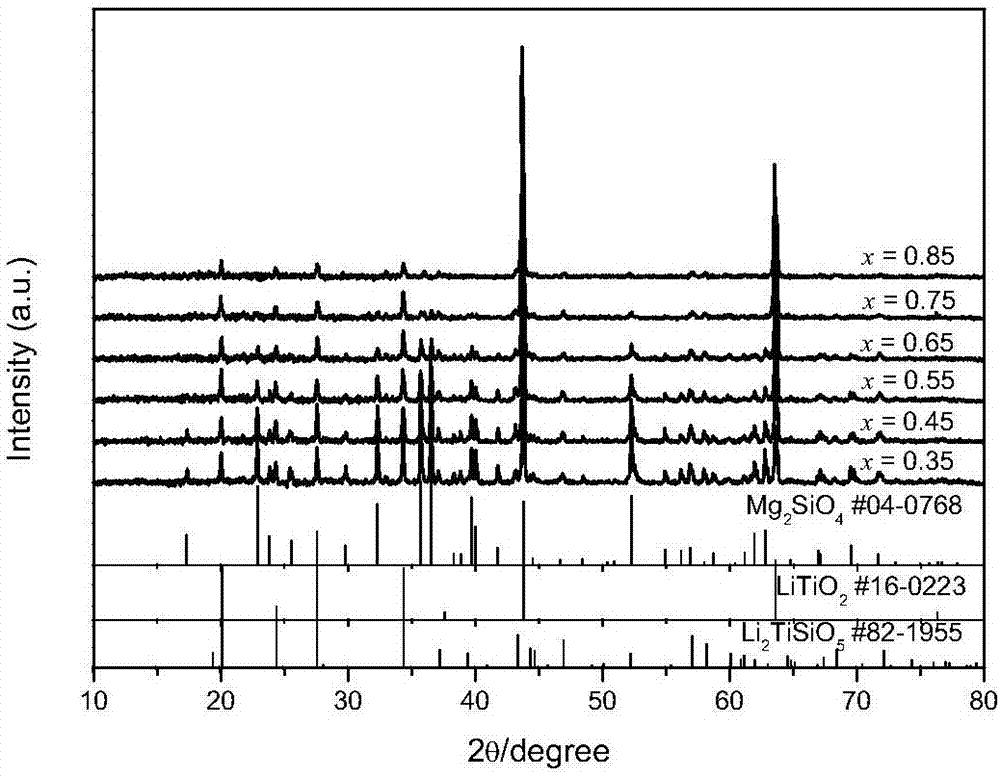

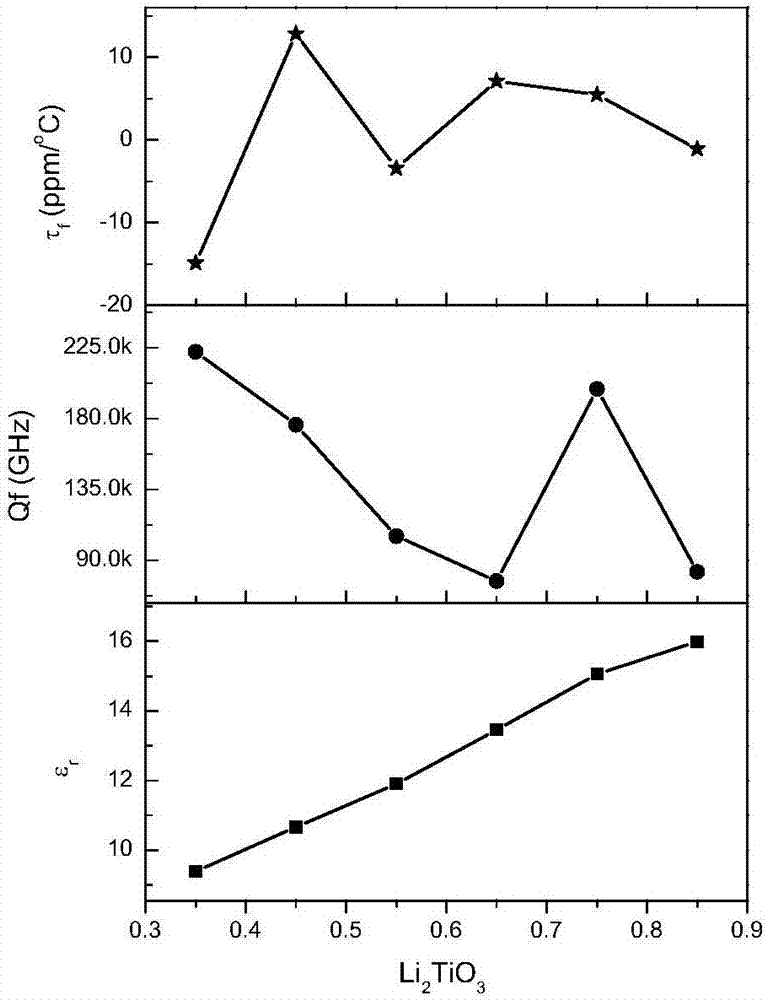

Mg2SiO4-Li2TiO3 compound system LTCC (low-temperature co-fired ceramic) material and preparation method thereof

A system and raw material technology, applied in the field of microwave electronic ceramic materials and its manufacturing, can solve problems such as high sintering temperature, failure to meet application requirements, and large deviation of resonance frequency temperature coefficient from zero, etc., to achieve high application prospects and value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below with reference to the accompanying drawings.

[0024] Step 1: Combine analytically pure MgO and SiO 2 Molar ratio MgO:SiO 2 = 2:1 Weighing and configuring raw materials; ball mill the prepared raw materials once to mix the raw materials evenly, add deionized water according to the mass ratio of powder and deionized water at 1:1, and ball mill for 4 hours at the ball milling speed of 300rpm. After ball milling, dry the powder at 120°C for later use.

[0025] Step 2: Pass the dried powder obtained in Step 1 through a 60-mesh sieve, put it into a crucible for compaction after sieving, and heat it up to 1350°C at a rate of 2°C / min for pre-burning, keep it warm for 4 hours, and cool with the furnace get Mg 2 SiO 4Pre-fired.

[0026] Step 3: Add analytically pure Li 2 CO 3 and TiO 2 Moore Billy 2 CO 3 :TiO 2 = 2:1 Weighing and configuring raw materials; ball mill the prepared raw materials once to mix ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com