Composite fully-degradable material and preparation method thereof

A technology for fully degradable and degradable plastics, applied in the field of composite fully degradable materials and their preparation, can solve the problems of soil structure damage, not effectively solved, hindering productivity, etc., to eliminate different degradation rates, improve practicability, and reduce entanglement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

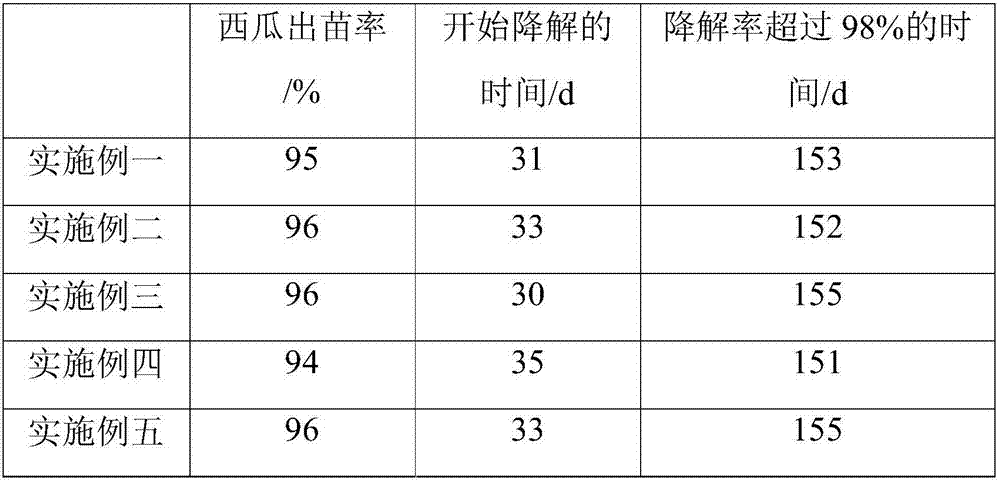

Embodiment 1

[0039] The present invention provides a composite fully degradable material, the composite fully degradable material adopts a double-layer film structure, including a first layer of film and a second layer of film; wherein, the raw material components of the first layer of film, in parts by weight, include 0.01 part by weight of iron stearate, 0.1 part by weight of barium stearate, 0.05 part by weight of 2,6-di-tert-butyl-p-cresol, 9 parts by weight of low density polyethylene LD662 and 90.74 parts by weight of linear low density polyethylene 7042; The raw material components of the second film, in parts by weight, include: 30 parts by weight of PBAT with a number-average molecular weight of 8000, 10 parts by weight of PLA 6201D, 2 parts by weight of triacetin, 0.05 part by weight of iron stearate, iron oxide 0.05 parts by weight, 5 parts by weight of low density polyethylene LD662 and 62.9 parts by weight of linear low density polyethylene 7042.

[0040] According to the abov...

Embodiment 2

[0045] The present invention provides a composite fully degradable material, the composite fully degradable material adopts a double-layer film structure, including a first layer of film and a second layer of film; wherein, the raw material components of the first layer of film, in parts by weight, include 0.05 part by weight of manganese stearate, 0.2 part by weight of magnesium stearate, 0.2 part by weight of 4,4-isopropylidene bis(phenol salicylate), 0.1 part by weight of 2,4,6-tri-tert-butylphenol , 6 parts by weight of low density polyethylene 2012TN26, 20 parts by weight of linear low density polyethylene 9020 and 73.45 parts by weight of linear low density polyethylene 7042T; the raw material components of the second layer film are calculated in parts by weight, including: the number average molecular weight is 30000 parts by weight of PBAT 40 parts by weight, PLA 4032D 10 parts by weight, 2 parts by weight of triacetin, 0.15 parts by weight of manganese stearate, 0.05 p...

Embodiment 3

[0051] The present invention provides a composite fully degradable material, the composite fully degradable material adopts a double-layer film structure, including a first layer of film and a second layer of film; wherein, the raw material components of the first layer of film, in parts by weight, include 0.1 part by weight of titanium dioxide, 0.3 part by weight of calcium stearate, 0.3 part by weight of p-tert-butylphenyl salicylate, 0.15 part by weight of 4-hydroxymethyl-2,6-di-tert-butylphenol, low density polyethylene 2426H 10 parts by weight, 79.15 parts by weight of linear low-density polyethylene 218W, and 10 parts by weight of linear low-density polyethylene 222; the raw material components of the second layer film, in parts by weight, include: 50 parts by weight of PBAT with a number average molecular weight of 20,000, PLA 15 parts by weight of 6201D, 3 parts by weight of triacetin, 0.1 part by weight of titanium dioxide, 0.1 part by weight of n-octyl ferrocene, 5 pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com