A dry farming agricultural district biological fully-degradable material and a method for preparing the same

A technology for degrading materials and degrading plastics, applied in the field of biodegradable materials and their preparation in dry farming areas, can solve the problems of poor strength, stretchability and light transmittance, not easy to degrade, and not suitable for mechanical film laying, etc., so as to eliminate degradation. Different rates, different elimination rates of degradation, and excellent effects of temperature regulation and moisture retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

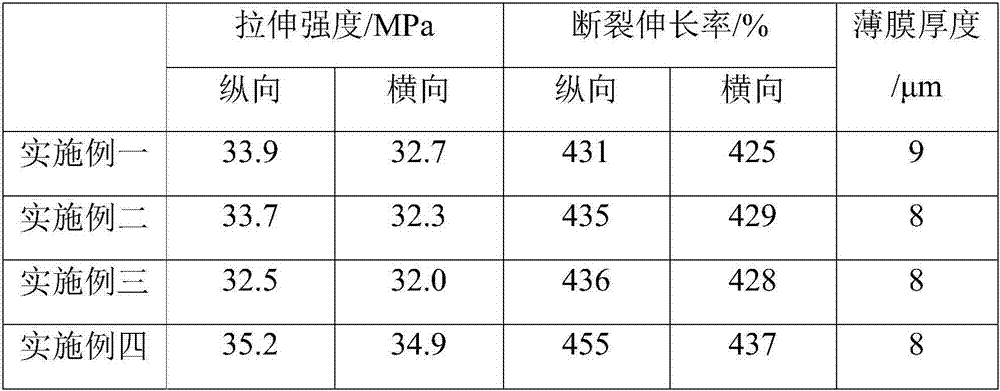

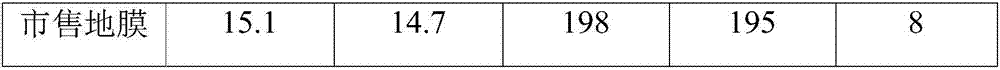

Examples

Embodiment 1

[0036] The invention provides a degradable material, which adopts a double-layer film structure, including a first layer of film and a second layer of film; wherein, the raw material components of the first layer of film are in parts by weight, 0.03 parts by weight of praseodymium stearate , 0.30 parts by weight of hydrotalcite powder, 0.05 parts by weight of n-octyl ferrocene, 0.50 parts by weight of strontium stearate, 0.50 parts by weight of tourmaline powder, 0.30 parts by weight of resorcinol monobenzoate, 4-hydroxymethyl - 0.05 parts by weight of 2,6-di-tert-butylphenol, 30 parts by weight of high-density polyethylene 6070, 20 parts by weight of low-density polyethylene 2012TN26 and 20 parts by weight of linear low-density polyethylene 7042T; the raw material components of the second layer of film In parts by weight, it includes: 30 parts by weight of polylactic acid 4032D, 10 parts by weight of nano silicon dioxide with a particle diameter of 50nm, 1 part by weight of 3-...

Embodiment 2

[0042] The invention provides a kind of degradable material, and this degradable material adopts double-layer film structure, comprises first layer film and second layer film; Wherein, the raw material component of first layer film comprises 0.05 weight of praseodymium stearate 0.10 parts by weight of hydrotalcite powder, 0.10 parts by weight of n-octanoyl ferrocene, 0.10 parts by weight of strontium stearate, 0.90 parts by weight of tourmaline powder, 0.10 parts by weight of resorcinol monobenzoate, 4-methylol 0.20 parts by weight of base-2,6-di-tert-butylphenol, 50 parts by weight of high-density polyethylene CH2802, 10 parts by weight of low-density polyethylene LD6001 and 30 parts by weight of linear low-density polyethylene FV149M; the raw material components of the second layer of film In parts by weight, it includes: 70 parts by weight of polylactic acid 6201D, 1 part by weight of nano silicon dioxide with a particle diameter of 20nm, 5 parts by weight of 3-aminopropyltr...

Embodiment 3

[0048] The invention provides a kind of degradable material, and this degradable material adopts double-layer film structure, comprises first layer film and second layer film; Wherein, the raw material component of first layer film comprises 0.04 weight of praseodymium stearate 0.20 parts by weight of hydrotalcite powder, 0.08 parts by weight of n-octyl ferrocene, 0.30 parts by weight of strontium stearate, 0.60 parts by weight of tourmaline powder, 0.20 parts by weight of resorcinol monobenzoate, 4-methylol 0.15 parts by weight of base-2,6-di-tert-butylphenol, 40 parts by weight of high-density polyethylene 5502, 15 parts by weight of low-density polyethylene 2426H and 25 parts by weight of linear low-density polyethylene 0218D; the raw material group of the second layer of film In terms of parts by weight, it includes: 50 parts by weight of polylactic acid 3251D, 8 parts by weight of nano-silica with a particle size of 200nm, 3 parts by weight of 3-aminopropyltriethoxysilane,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com