Patents

Literature

31 results about "Resorcinol monobenzoate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low-temperature-resistant automobile nylon composite and preparation method thereof

InactiveCN104046003AImprove low temperature resistanceHigh impact strengthISOCETYL PALMITATEHydroxystearic Acid

The invention discloses a low-temperature-resistant automobile nylon composite and a preparation method thereof. The low-temperature-resistant automobile nylon composite is prepared from the following raw materials by weight: 45 to 65 parts of nylon 11, 30 to 40 parts of nylon 1010, 15 to 20 parts of polyoxymethylene, 17 to 23 parts of bis[2-(2-butoxyethoxy)ethyl] adipate, 12 to 18 parts of di-iso-butyl ester nylon acid, 10 to 15 parts of potassium hexatitanate whisker, 4 to 7 parts of zirconium silicate, 2.5 to 4.5 parts of isocetyl palmitate, 2 to 3 parts of hydroxystearic acid, 1 to 2 parts of barium laurate, 1 to 2 parts of barium myristate, 10 to 15 parts of resorcinol monobenzoate, 3 to 6 parts of vitamin E, 2 to 4 parts of distearyl alcohol pentaerythritol diphosphite, 1 to 2 parts of hydroxyl-aluminum p-tert-butyl benzoate, 1.5 to 2.5 parts of 3,4-dimethyl dibenzylidene sorbitol, 10 to 15 parts of oil shale residue, 8 to 12 parts of calcined clay, 5 to 10 parts of barite powder and 10 to 15 parts of modified kaolin. The nylon composite provided by the invention has excellent low temperature performance and can even be normally used at a low temperature of -50 DEG C; moreover, the nylon composite has high impact strength toughness, bending strength and rigidity, effectively prolongs the service life of a nylon material and broadens the application scope of the nylon material.

Owner:ANHUI ANLAN MOLD

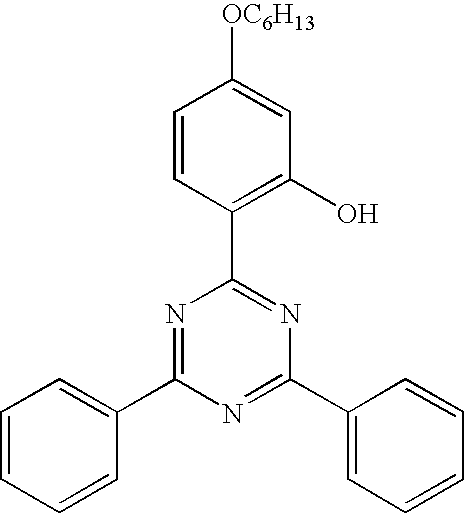

Transparent, low-flammability, UV-resistant film made from a crystallizable thermoplastic, its use and process for its production

InactiveUS7138176B2Good orientationMaintain good propertiesGain controlSynthetic resin layered productsThermoplastic2-hydroxybenzophenone

The present invention relates to a transparent, low-flammability, UV-resistant, oriented film made from a crystallizable thermoplastic and having a thickness of from 5 to 300 μm. The film comprises at least one UV stabilizer and at least one flame retardant, and at least the flame retardant, and preferably also the UV stabilizer, is fed directly as a masterbatch to the crystallizable thermoplastic during production of the film. The film may have one or more layers, and the UV stabilizer may have been selected from the group consisting of the 2-hydroxybenzophenones, the 2-hydroxybenzotriazoles, the organonickel compounds, the salicylic esters, the cinnamic ester derivatives, the resorcinol monobenzoates, the oxanilides, the hydroxybenzoic esters, the sterically hindered amines and triazines, and the flame retardant may be an organic phosphorus compound, in particular an organic phosphorus compound soluble in polyethylene terephthalate.

Owner:MITSUBISHI POLYESTER FILM

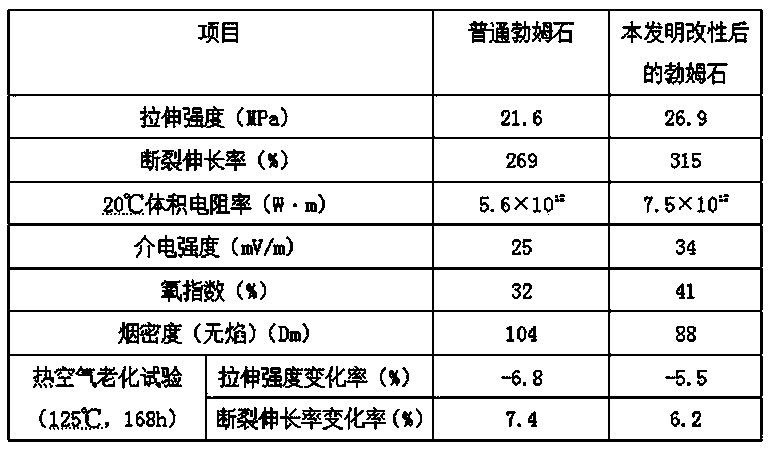

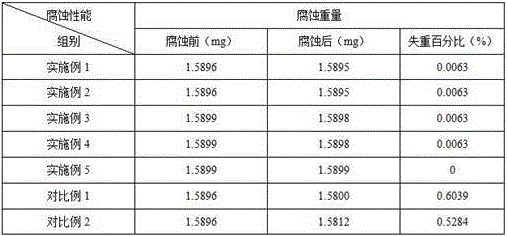

Modified boehmite for heatproof flame retardant cable materials and preparation method thereof

InactiveCN104163939AAcid resistantFlame retardantPigment treatment with macromolecular organic compoundsPigment treatment with organosilicon compoundsPhosphateBenzoic acid hydrazide

The invention discloses modified boehmite for heatproof flame retardant cable materials and a preparation method thereof, and the modified boehmite is made from the following raw materials by weight: 100 parts of boehmite, 15-25 parts of expanded graphite powder, 3-6 parts of triglycidyl isocyanurate, 20-30 parts of nano black stone, 10-15 parts of ceramic beads, 10-15 parts of butyl benzyl phthalate, 2-3 parts of 4-amion-2,2,6,6-tetramentylniperidine, 5-10 parts of phenyl isopropylphenyl phosphate, 1.5-2.5 parts of 2-hydroxy magnesium benzoate, 2-3 parts of p-hydroxy benzoic acid hydrazide, 4-6 parts of behenamide, 0.5-1.5 parts of resorcinol monobenzoate, 1-2 parts of dilauryl thiodipropionate and 3-5 parts of an auxiliary. The modified boehmite has the advantages of high in acid resistant, flame retardant and smoke suppression functions, good in filling effect, free of secondary pollution after combustion, low cost, and the like, not only can improve the flame retardant properties of the cable materials, but also can improve the heat resistance, corrosion resistance, dielectric property and mechanical strength of the cable materials.

Owner:滁州市富力克斯电线电缆有限公司

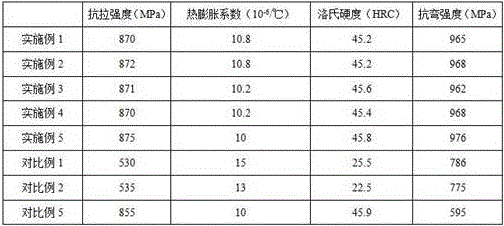

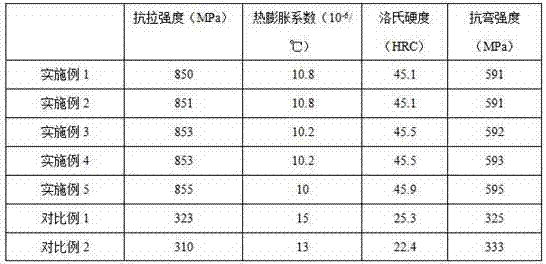

High-strength aluminum alloy door frame

The invention discloses a high-strength aluminum alloy door frame. The aluminum alloy door frame is prepared from, by weight, 81-85 parts of aluminum, 4-7 parts of tungsten, 7-10 parts of niobium, 13-16 parts of titanium, 12-15 parts of nickel, 8-11 parts of molybdenum, 9-12 parts of chromium, 15-18 parts of copper, 6-9 parts of manganese and 5-9 parts of silicon. Octoxy-benzophenone is adopted, resorcinol monobenzoate is adopted as an anti-aging agent, and polyethylene glycol is adopted as a dispersing agent. The aluminum alloy door frame is prepared from aluminum, tungsten, niobium, titanium, nickel, molybdenum, chromium, copper, manganese and silicon and has the beneficial effects of being high in strength, resistant to wear, resistant to aging and long in service life.

Owner:常熟市古里镇鑫良铝合金门窗厂

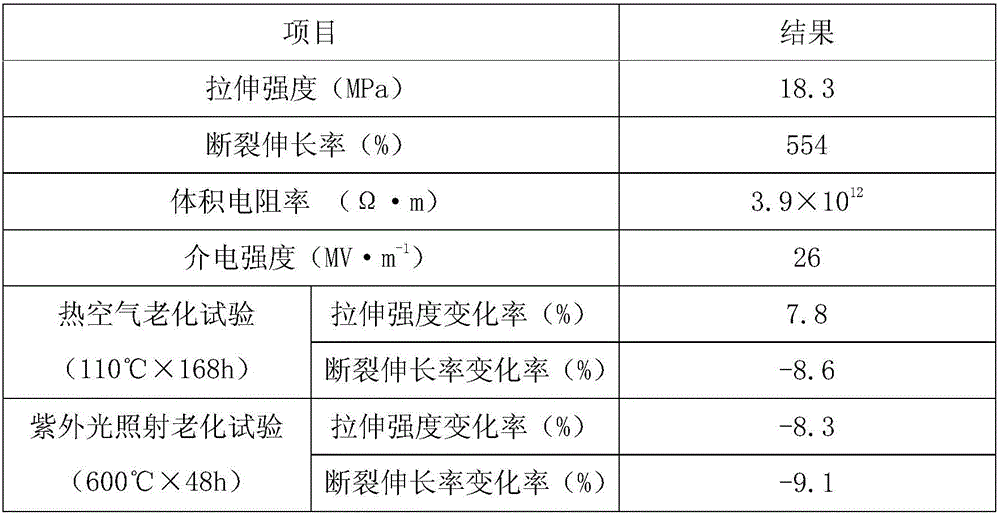

Tooth filling material and preparation method thereof

InactiveCN105902398AImprove mechanical propertiesImprove polishing effectImpression capsDentistry preparationsThermal dilatationPolymer science

The invention relates to a tooth filling material and a preparation method thereof. The tooth filling material includes, by mass, 15-35 parts of glycidyl methacrylate, 10-25 parts of Arabic gum, 5-20 parts of glass powder, 5-15 parts of silicon dioxide, 3-12 parts of nano montmorillonite, 1-6 parts of calcium carbonate, 0.5-3 parts of 1,6-hexanediol diacrylate, 0.8-3.5 parts of dicumyl peroxide, 0.3-1.5 parts of triethylene diamine, 0.2-1 part of EDTA, 0.2-1.2 parts of an organic tin stabilizer, 3-10 parts of zinc phosphate cement, and 0.1-0.5 parts of resorcinol monobenzoate. The tooth filling material has excellent mechanical performance and polishing performance, has the similar gloss and the similar coefficient of thermal expansion of a tooth, can effectively prevent edge micro-leakage and heat conductivity, has a good hole filling effect and is long in service life.

Owner:SUZHOU COSMETIC MATERIALS

Anticorrosive fireproof paint

InactiveCN104559528AImprove adhesionGood flexibilityFireproof paintsAntifouling/underwater paintsPolyvinyl alcoholPreservative

The invention discloses an anticorrosive fireproof paint which is composed of a base material, a preservative, an ultraviolet stabilizer, a curing agent and a flame retardant, wherein the base material is polyvinyl alcohol, the preservative is potassium sorbate, the ultraviolet stabilizer is resorcinol monobenzoate, the curing agent is resol, and the flame retardant is microcapsulated red phosphorus. The product is prepared from the base material, preservative, ultraviolet stabilizer, curing agent and flame retardant; and the prepared product has the advantages of favorable adhesion, excellent corrosion resistance, long service life, quick curing at normal temperature, favorable flexibility and wide adaptability, is convenient for construction, and has obvious effects in the aspect of fire hazard prevention.

Owner:SUZHOU AOLAX BUILDING MATERIALS

Outdoor feedwater anti-ageing PE tubular product and preparation method thereof

InactiveCN104098821AImprove aging resistanceImprove heat resistanceRigid pipesPhosphateDibutyltin dilaurate

The invention discloses an outdoor feedwater anti-ageing PE tubular product and a preparation method thereof. The outdoor feedwater anti-ageing PE tubular product is prepared from the following raw materials in parts by weight: 55-65 parts of high density polyethylene, 25-35 parts of poly diallyl terephthalate, 15-20 parts of bisphenol A type polyarylate, 4-7 parts of lignite wax, 3-5 parts of ethylene bis stearamide, 6-9 parts of methyl fluoride silicone oil, 2.5-4.5 parts of pentaerythritol monooleate, 10-15 parts of titanium white powder, 10-15 parts of organic montmorillonite, 1-2 parts of dibutyltin dilaurate, 2-4 parts of basic lead carbonate, 1.5-2.5 parts of ethyl-3-amino crotonate, 2-3 parts of diphenylthiourea, 1-2 parts of di(dioctylpyrophosphato) ethylene titanate, 4-8 parts of bis(2-ethylhexyl)phosphate, 18-24 parts of filling master batch, 2-3 parts of bis(2,4-di-tert-butylphenyl)pentaerythritol diphosphite, 1-2 parts of 2,4-di tertbutyl phenol, and 1-2 parts of resorcinol monobenzoate. The PE tubular product, provided by the invention, is good in age resistance and prominent in environmental stress crack resistance and anti-ultraviolet performance, has good heat resistance, flexibility, wear resistance and chemical corrosion resistance, and is long in service life.

Owner:ANHUI DINGYUAN ZHENYUN PLASTIC

High-bending-strength oral cavity repair material and preparation method thereof

InactiveCN106693045AGuaranteed basic mechanical strengthImprove wear resistanceTissue regenerationProsthesisMechanical propertyMaterials science

The invention discloses a high-bending-strength oral cavity repair material and a preparation method thereof, wherein the oral cavity repair material comprises the following components by the mass percentage: 8-12% of zinc oxide, 1-2% of cerium oxide, 0.5-1% of tantalum oxide, 0.2-0.5% of niobium oxide, 2-3% of borax, 1-3% of polyether-ether-ketone, 2-4% of sodium fluoride, 2-4% of sodium monofluorophosphate, 2-3% of sodium stannate, 8-10% of nano montmorillonite, 0.1-0.2% of triethylene diamine, 0.1-0.2% of resorcinol monobenzoate, and the balance zirconium oxide. With zirconium oxide as the main component, with zinc oxide as the supplement, with addition of cerium oxide, tantalum oxide and niobium oxide, the basic mechanical strength of the obtained oral cavity repair material is ensured, borax plays a bactericidal effect, polyether-ether-ketone enhances the wear resistance and corrosion resistance of the oral cavity repair material, sodium fluoride, sodium monofluorophosphate and sodium stannate synergetically enhance the bactericidal effect, nano montmorillonite helps all the components be evenly dispersed so as to improve the mechanical properties of the obtained material, and triethylene diamine and resorcinol monobenzoate help to improve the light stability of the product.

Owner:朱一军

Hydrotalcite-lanthanum stearate composite environmental protection stabilizer for PVC, and preparation method thereof

The present invention provides a hydrotalcite-lanthanum stearate composite environmental protection stabilizer for PVC, wherein the hydrotalcite-lanthanum stearate composite environmental protection stabilizer is prepared from the following raw materials by weight: 20-30 parts of modified magnesium aluminum hydrotalcite, 10-12 parts of monobutyl tin trichloride, 1-3 parts of diisooctyl phenyl phosphite, 15-20 parts of lanthanum stearate, 6-8 parts of calcium adipate, 15-18 parts of zinc adipate, 2-4 parts of epoxidized soybean oil, 5-6 parts of sorbitol, 2-4 parts of resorcinol monobenzoate, 10-12 parts of triethyl citrate, 1-2 parts of carnauba wax, and 8-10 parts of bentonite. According to the present invention, the PVC stabilizer has characteristics of good thermal stability, good processing performance, environmental protection, no toxicity, low cost, good plasticity and balance torque reducing during the PVC processing process, and low cost.

Owner:HWASU

High-viscosity polyurethane sealant

ActiveCN104356993AStrong stickinessQuality improvementNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesSealantTackifier

The invention discloses a high-viscosity polyurethane sealant. The polyurethane sealant is prepared from polyurethane resin, a tackifier, a crosslinking agent, a plasticizer, an anti-scratching agent and an ultraviolet absorbent, wherein the tackifier is pentaerythritol ester of rosin, the crosslinking agent is hydroxy-propyl acrylate, the plasticizer is dioctyl phthalate, the anti-scratching agent is palm wax, and the ultraviolet absorbent is resorcinol monobenzoate. The high-viscosity polyurethane sealant is prepared from polyurethane resin and five additives, namely the tackifier, the crosslinking agent, the plasticizer, the anti-scratching agent and the ultraviolet absorbent, and the prepared product has the advantages of strong viscosity, high quality, convenience in processing, good scratching resistance, aging resistance, discoloring resistance and good using effect.

Owner:广州市百庄复合材料有限公司

Phenolic resin and urea resin composite modified plastic

The invention discloses phenolic resin and urea resin composite modified plastic, comprising phenolic resin, urea resin and additives, wherein the additives comprise a toughening agent, a plasticizer, a weathering resisting agent, a compatilizer and a coupling agent, the toughening agent is polyvinyl alcohol, the plasticizer is diamyl phthalate, the weathering resisting agent is resorcinol monobenzoate, the compatibilizer is phthalic anhydride, and the coupling agent is vinyl triethoxysilane. The prepared phenolic resin and urea resin composite modified plastic has the effects of weathering resistance, good toughness, excellent dimensional stability and the like.

Owner:苏州市双赢包装材料有限公司

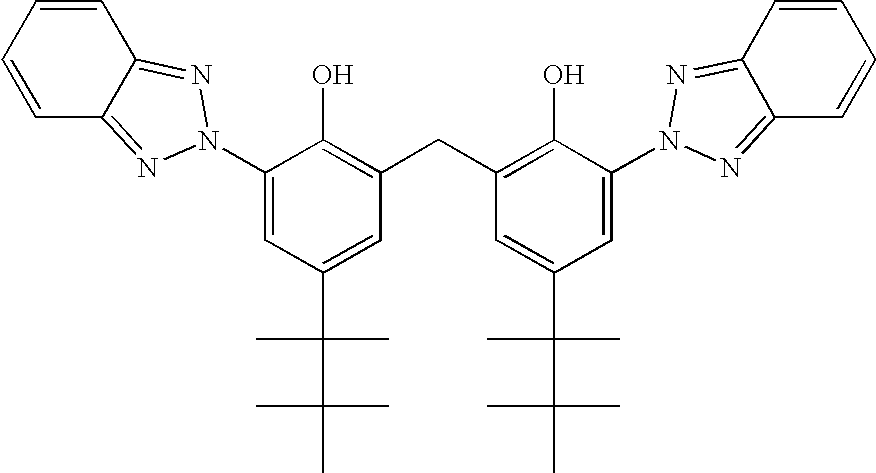

Locomotive cracking resistant cable material and preparation method thereof

InactiveCN104804294AImprove crack resistanceAvoid crackingPlastic/resin/waxes insulatorsLinear low-density polyethyleneCrack resistance

The invention discloses a locomotive cracking resistant cable material and a preparation method thereof. The locomotive cracking resistant cable material is prepared from the following raw materials in parts by weight: 78-94 parts of LLDPE, 20-30 parts of PPTA, 22-28 parts of basalt fibre, 15-20 parts of ATBC, 18-24 parts of a composite flame retardant, 4-6 parts of trimethylolpropane glyceryl cocoate, 3-5 parts of dodecanoic acid, 3-4 parts of dibutyltin dilaurate, 2-3 parts of PDOP, 2-3 parts of aluminium hydroxy distearate, 13-17 parts of potassium titanate whisker, 10-15 parts of cork powder, 2-3 parts of resorcinol monobenzoate and 1-2 parts of nickel dibutyldithiocarbamate. The cable material is excellent in crack resistance, cannot easily crack under the long-term actions of low temperature and impact force, and the like, and is high in mechanical strength, better in electrical insulating property and flame retardant property, organically integrates the electrical insulating property, flame retardant property, mechanical performance and cracking resistance, and is easy to manufacture, wide in material selecting range, lower in cost and good in use performance.

Owner:ANHUI KANGLIYA CO LTD

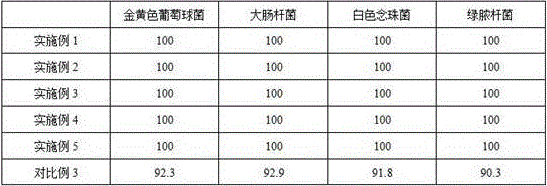

Easily-degradable anti-microbial nylon composite material and preparation method thereof

The invention discloses an easily-degradable anti-microbial nylon composite material and a preparation method thereof. The preparation method comprises the steps of with nylon resin, aluminum titanate fiber, ethyl acetate amide and hydroxystearic acid as the main components, adding N-ethylene amide distearate, resorcinol monobenzoate, octadecanoyl tributyl citrate, germanium powder, spinel powder, cetearyl alcohol, butylhydroxyanisole, zinc ricinoleate, dibutyltin diacetate, barium laurate soap, a silane coupling agent, an antioxidant and an antioxidant, and carrying out processes of stirring grinding, high-temperature calcination, ultrasonic dispersion, high-temperature smelting, extrusion molding and the like, so as to obtain the nylon composite material. The prepared nylon composite material has wide anti-microbial range, good sterilizing effect and excellent degrading performance, can meet the industrial requirements and further has a relatively good application prospect.

Owner:刘平

Polyvinyl chloride cable material with good light and heat stability and preparation method thereof

InactiveCN106065141AExtended service lifeGood light stabilityPlastic/resin/waxes insulatorsApatitePolyvinyl chloride

The invention discloses a polyvinyl chloride cable material with good light and heat stability and a preparation method thereof. The polyvinyl chloride cable material is prepared from 79-92 parts by weight of polyvinyl chloride, 36-48 parts by weight of polyvinylpyridine, 15-20 parts by weight of resorcinol monobenzoate, 18-24 parts by weight of pandermite, 20-30 parts by weight of a copolymer of vinyl chloride and vinyl isobutyl ether, 22-34 parts by weight of picrite, 8-13 parts by weight of triglycidyl isocyanurate, 6-7 parts by weight of a di-n-octyltin moleate polymer, 8-10 parts by weight of butyl stearate, 14-22 parts by weight of titanium dioxide and 13-21 parts by weight of apatite. Through polyvinyl chloride cable material formula improvement such as use of polyvinylpyridine, the copolymer of vinyl chloride and vinyl isobutyl ether, aromatic hydrocarbon-modified terpene resin, pine soot, epoxidized methyl acetoricinoleate and titanium dioxide, the prepared cable material has good light stability, good heat stability and good weatherability, greatly reduces polyvinyl chloride cable material light and heat aging rates and prolongs a service life of the polyvinyl chloride cable material.

Owner:ANHUI SAIHUA CABLE

Oral repair material and preparation method thereof

InactiveCN106904961AGuaranteed basic mechanical strengthImprove wear resistanceImpression capsDentistry preparationsMechanical propertyMaterials science

The invention discloses an oral repair material and a preparation method thereof. The oral repair material comprises the following components in percentage by mass: 8-12% of zinc oxide, 1-2% of cerium oxide, 0.5-1% of tantalum oxide, 2-3% of borax, 1-3% of polyetheretherketone, 2-4% of sodium fluoride, 2-4% of sodium monofluorophosphate, 2-3% of sodium stannate, 8-10% of nanometer montmorillonite, 0.1-0.2% of triethylene diamine, 0.1-0.2% of resorcinol monobenzoate and the balance of zirconium oxide. The zirconium oxide is used as a main material, the zinc oxide is used as an auxiliary material, and the cerium oxide and the tantalum oxide are also added, so that the basic mechanical strength of the obtained oral repair material is ensured; the borax achieves a bactericidal effect; the polyetheretherketone improves the wear resistance and the corrosion resistance of the oral repair material; the sodium fluoride, the sodium monofluorophosphate and the sodium stannate are coordinated to improve the bactericidal effect; the nanometer montmorillonite facilitates uniform dispersion of the components so as to improve the mechanical properties of the obtained material; the triethylene diamine and the resorcinol monobenzoate help to improve the light stability of the product.

Owner:朱一军

Waterproof paint for ground decoration and preparation method thereof

InactiveCN104893432AImprove waterproof performanceImprove wear resistanceUnspecified rubber coatingsChloropene polymer coatingsPolyvinyl alcoholSodium phosphates

The invention relates to a waterproof paint for ground decoration and a preparation method thereof. The paint comprises the following components in parts by weight: 17-29 parts of latex rubber, 8-16 parts of neoprene latex, 3-11 parts of butyl glycidyl ether, 0.7-2.3 parts of polyvinyl alcohol, 0.06-0.18 part of alkyl phenol polyoxyethylene, 0.1-0.3 part of ethyl acetate, 20-34 parts of butanol, 0.06-0.28 part of sodium hexametaphosphate, 1.2-5.5 parts of trimethylolpropane, 1.6-4.2 parts of barite, 3-10 parts of ceramic powder, 0.2-0.6 part of medical stone, 2-7 parts of aluminum oxide, 1-4 parts of ferric oxide, 0.06-0.15 part of resorcinol monobenzoate and 0.03-0.11 part of isocaprylic salt. A coating formed by the paint provided by the invention has excellent waterproof performance, wearproof performance, chemical corrosion resistance and flexibility.

Owner:SUZHOU DEXIANG DECORATION ENG

Universal waterborne hub baking paint

The invention discloses universal waterborne hub baking paint. Waterborne acrylic resin and amine resin serve as main base materials, water serves as a solvent, any organic solvents are omitted, the paint is nontoxic and environmentally friendly, environments are not affected, isopropyl alcohol and various additives are added to perform stirring to obtain mixed liquid, 2-[acetoxyl (polyoxyethylene) propyl] heptamethyltrisiloxane, 1, 1, 3, 3-tetramethyl-1, 3 di [3-(epoxy ethyl methoxyl) propyl] disiloxane, dicontraction tripropanediol ethylene diacrylate, 2, 2, 6, 6-tetramethyl-4-piperidine stearate, resorcinol mono benzoate and double (2, 2, 6, 6-tetramethyl-3, 5-pimelic keto acid) calcium are added into the mixed liquid, high abrasion resistance of the prepared hub baking paint is ensuredunder the combined action of six substances, the baking paint has still excellent abrasion resistance after being irradiated by ultraviolet rays, impact resistance and toughness are excellent, high-temperature resistance, water resistance and salt fog resistance are excellent, and the baking paint can completely replace traditional paint and can be widely applied to various metal and alloy materials.

Owner:温州环诺新材料科技有限公司

Expandable polystyrene anti-aging flame-retardant plate

The invention discloses an expandable polystyrene anti-aging flame-retardant plate and relates to the field of preparation of expandable polystyrene. The expandable polystyrene anti-aging flame-retardant plate comprises well cured expandable polystyrene particles, flame retardant slurry and anti-aging agent slurry, wherein the weight part ratio of the expandable polystyrene particles to the flame retardant slurry to the anti-aging agent slurry is (9-10):1:(0.5-1); the flame retardant slurry comprises the following components in parts by weight: 4-5 parts of ammonium phosphate, 0.4-0.5 part of antimony trioxide, 2-3 parts of aluminium chloride, 0.5-1 part of zinc borate, 4-5 parts of magnesium chloride, 3-4 parts of citric acid and 7-8 parts of deionized water; and the anti-aging agent slurry comprises the following components in parts by weight: 4-5 parts of 6-ethoxy-2,2,4-trimethyl-1,2-dihydroquinoline, 2-2.5 parts of N-cyclohexyl-N'-phenyl-P-phenylenediamine, 1-1.5 parts of 4-benzoyloxy-2,2,6,6-tetramethyl piperidine, 2-3 parts of 2,4-dihydroxy benzophenone, 1-2 parts of resorcinol monobenzoate and 10-11 parts of an ethanol solution. By adopting the technical scheme, the fireproof performance of the expandable polystyrene can be enhanced, the service life of the expandable polystyrene is prolonged, and then the generation of waste and old plates is reduced and the environment is protected.

Owner:遵义荣盛包装材料有限公司

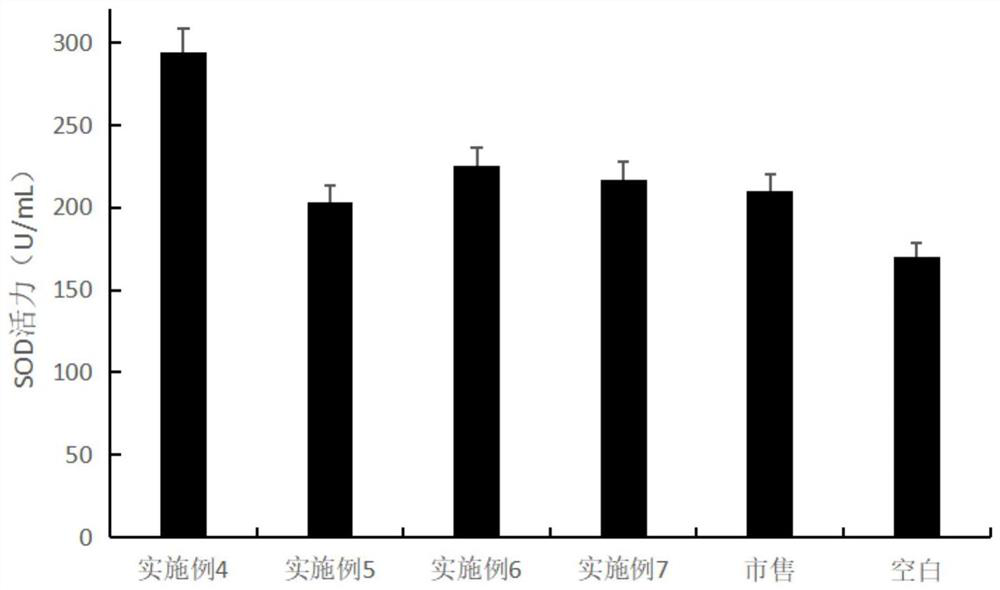

Cosmetic composition, cosmetic and preparation method thereof

InactiveCN111643443AProtect moistureIncrease elasticityCosmetic preparationsAntipyreticBenzoic acidPolymer science

The invention provides a cosmetic composition. The cosmetic composition is prepared from the following raw materials: nostoc commune extract microspheres, an ultraviolet light absorber, a transdermalabsorption enhancer, bergamot oil, lemon oil, shell powder, casein hydrolysate, sorbitan monolaurate and resorcinol monobenzoate. The invention further provides a cosmetic and a preparation method thereof. The preparation method is simple, the obtained nostoc commune extract has good effects of diminishing inflammation and removing acnes, active substances in the prepared cosmetic are protected bythe microspheres, the microspheres are rubbed and broken when the cosmetic is used, the activity of the active substances is protected from being damaged, the use effect is good, and the cosmetic composition has a wide application prospect.

Owner:深圳市智为时代科技有限公司

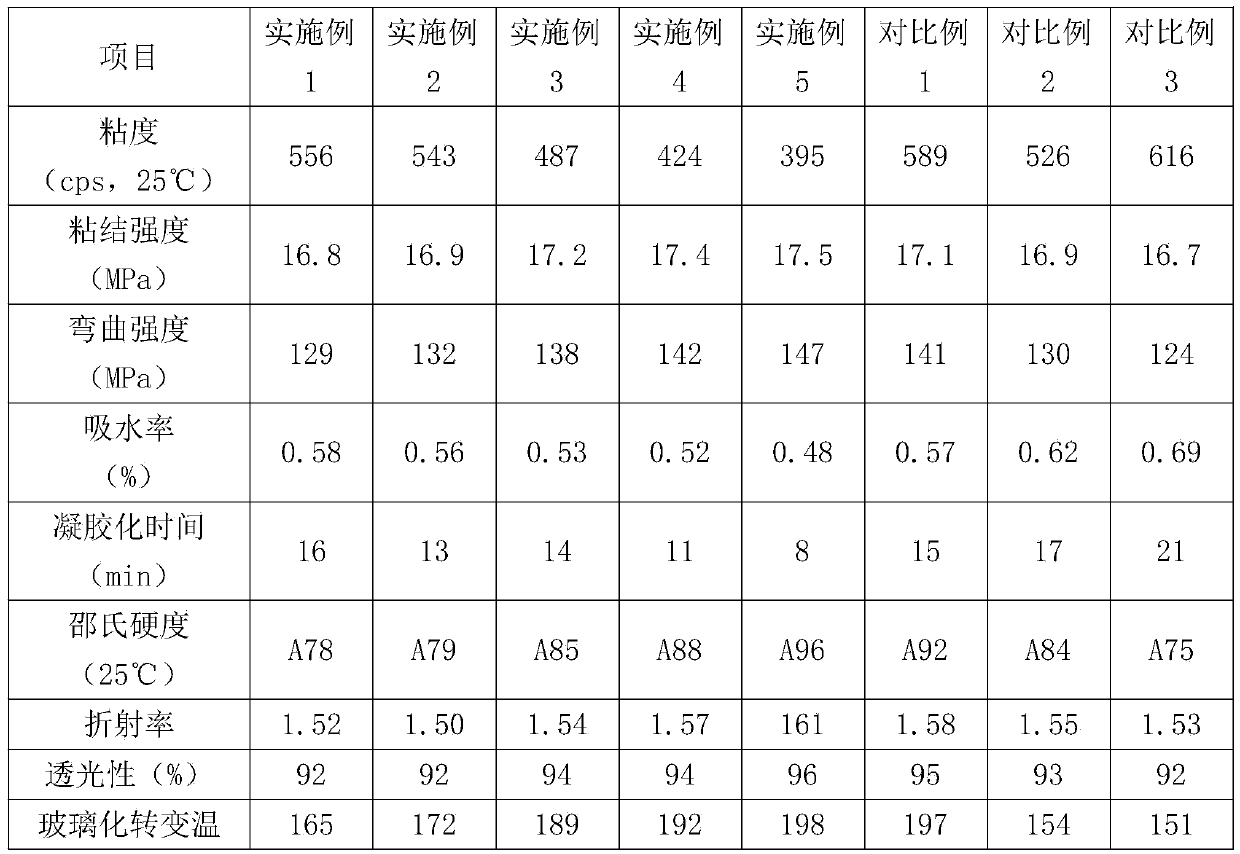

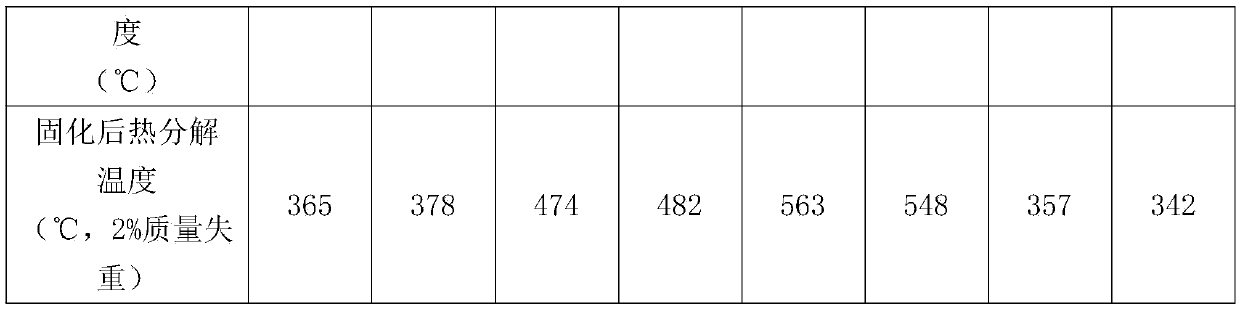

Epoxy encapsulation adhesive for high power LED encapsulation and preparation method for epoxy encapsulation adhesive and use of epoxy encapsulation adhesive

InactiveCN105368363AHigh refractive indexGood resistance to UV radiationNon-macromolecular adhesive additivesMacromolecular adhesive additivesAdhesiveRefractive index

The present invention discloses an epoxy encapsulation adhesive for high power LED encapsulation and a preparation method for an epoxy encapsulation adhesive and use of the epoxy encapsulation adhesive. The encapsulation adhesive consists of 42-47% of a component A and 53-58% of a component B by mass percentage. The component A is prepared from 19.85-80% of bisphenol F epoxy resin, 19.85-80% of phenolic aldehyde modified organosilicone resin and 0.15-0.25% of polyether modified polysiloxane by mass percentage, and the component B is prepared from 14-27% of a Korean pine extraction liquid, 72-85% of adipic dihydrazide, 0.4-1.0% of resorcinol monobenzoate and 0.6-1.2% of 4-benzoyloxyl-2,2,6,6-tetramethylpiperidine by mass percentage. The encapsulation adhesive disclosed by the present invention is resistant to high temperature, resistant to ultraviolet radiation, good in light transmittance, high in refractive index, simple in process and low in cost, so that the encapsulation adhesive can be widely applied to the high power LED encapsulation field.

Owner:深圳市极客智能科技有限公司

Polyethylene (PE) pipe with high tensile strength

The invention discloses a polyethylene (PE) pipe with high tensile strength. The PE pipe is prepared from the following components: polyvinyl resin, diisononyl phthalate, dicapryl phthalate, azole stearate, epoxy soybean oil, 2-(2'-5-methylphenyl) benzotriazole, and resorcinol monobenzoate. By adopting the way, the PE pipe with high tensile strength has the advantages that tissues of pipes are compact, a shape of a surface is regular, a cross section has a porous reticular structure, the PE pipe has good tensile strength, and the fracture still cannot be occurred under an effect of extremely strong external force.

Owner:TAICANG CHENZHOU PLASTIC

Surface treatment method for connecting device for modular buildings

InactiveCN106010065AExcellent heat and humidity resistanceReduce interactionBuilding constructionsCoatingsAdhesiveSilanes

The invention discloses a surface treatment method for a connecting device for modular buildings. The method comprises the following steps: preparing a prepolymer from raw materials including acrylic acid, N-hydroxymethyl acrylamide, 1,4-cyclohexanedimethanol diacrylate, N-vinyl pyrrolidone, lauryl methacrylate, iso-tridecanol polyoxyethylene ether and resorcinol monobenzoate; preparing an adhesive from raw materials including 4,4'-di(trifluoromethoxy) azobenzene, dicumyl peroxide, tetraglycidyl ether tetraphenyl ethane, lauryl methacrylate, maleic anhydride and 4-dimethylaminopyridine; preparing primer from raw materials including hydroxyl silicon resin, dimethyl imidazole, solid amine, vinyl trimethoxy silane, copper phthalocyanine and vinyl cyclohexene dioxide; treating the connecting device and completing the surface treatment of the connecting device for the modular buildings.

Owner:BOCA HI TECH PRECISION

Surface-treated connecting device for modular building

InactiveCN107828305AAvoid security issuesStrong adhesionBuilding constructionsCoatingsPOLYOXYETHYLENE ETHERN-hydroxymethylacrylamide

Owner:BOCA HI TECH PRECISION

A high viscosity polyurethane sealant

ActiveCN104356993BStrong stickinessQuality improvementNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPentaerythritolPlasticizer

The invention discloses a high-viscosity polyurethane sealant. The polyurethane sealant is prepared from polyurethane resin, a tackifier, a crosslinking agent, a plasticizer, an anti-scratching agent and an ultraviolet absorbent, wherein the tackifier is pentaerythritol ester of rosin, the crosslinking agent is hydroxy-propyl acrylate, the plasticizer is dioctyl phthalate, the anti-scratching agent is palm wax, and the ultraviolet absorbent is resorcinol monobenzoate. The high-viscosity polyurethane sealant is prepared from polyurethane resin and five additives, namely the tackifier, the crosslinking agent, the plasticizer, the anti-scratching agent and the ultraviolet absorbent, and the prepared product has the advantages of strong viscosity, high quality, convenience in processing, good scratching resistance, aging resistance, discoloring resistance and good using effect.

Owner:广州市百庄复合材料有限公司

Anti-ultraviolet automobile paint film

InactiveCN109957333AImprove antioxidant capacityHigh hardnessAnti-corrosive paintsPolyester coatingsCellulosePolyester

The invention discloses an anti-ultraviolet automobile paint film. The automobile paint film solvent comprises in percent by weight: 70% of vinyl resin, 21% of polyester cellulose, 53% of magnesium dioxide, 12% of a light stabilizer HPT, 16% of resorcinol monobenzoate, 13% of benzotriazole chloride, 3% of magnesium oxide, and 6% of sodium oxide; and the automobile paint film solvent finished product is prepared by adding 6% of deionized water. The painting process steps are as follows: cleaning an automobile body, performing clay adsorption treatment, performing rubber edge protection, polishing the automobile paint, coating a gloss restoring agent, performing degreasing treatment after cleaning the automobile body, coating the automobile film, performing spraying with a spraying gun afteradding a film coating agent, and performing clean washing after the film coating agent is remained for 30 min. The material has strong antioxidant property, the penetration rate of acidic substancesin the common automobile paint is 26%, and the penetration rate of acidic substances decreases to 1-2% after coating a nano automobile cover. The automobile film is successfully protected from damagesof vinegar rain and other acidic substances by the automobile cover without oxidation itself.

Owner:牛华

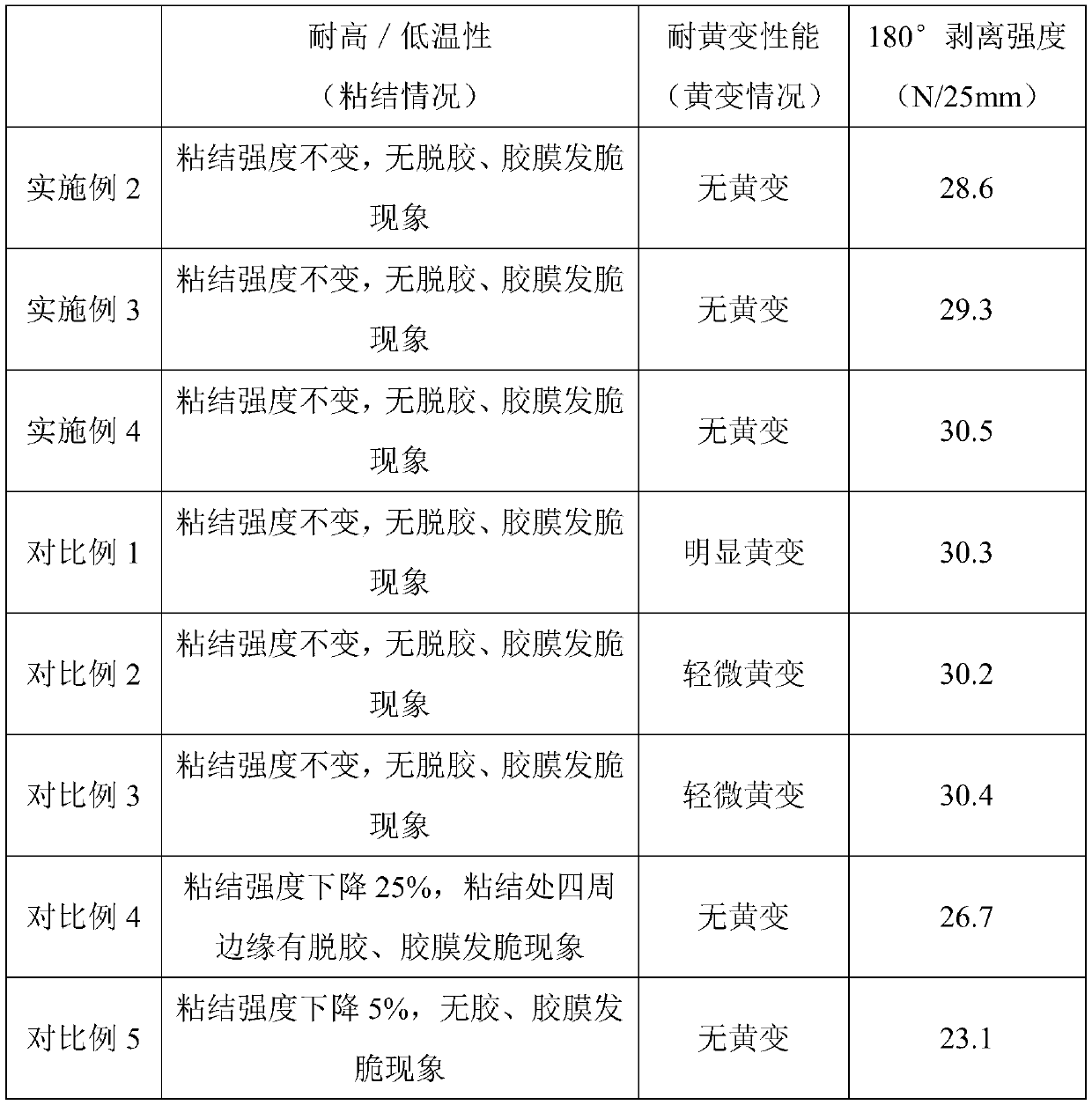

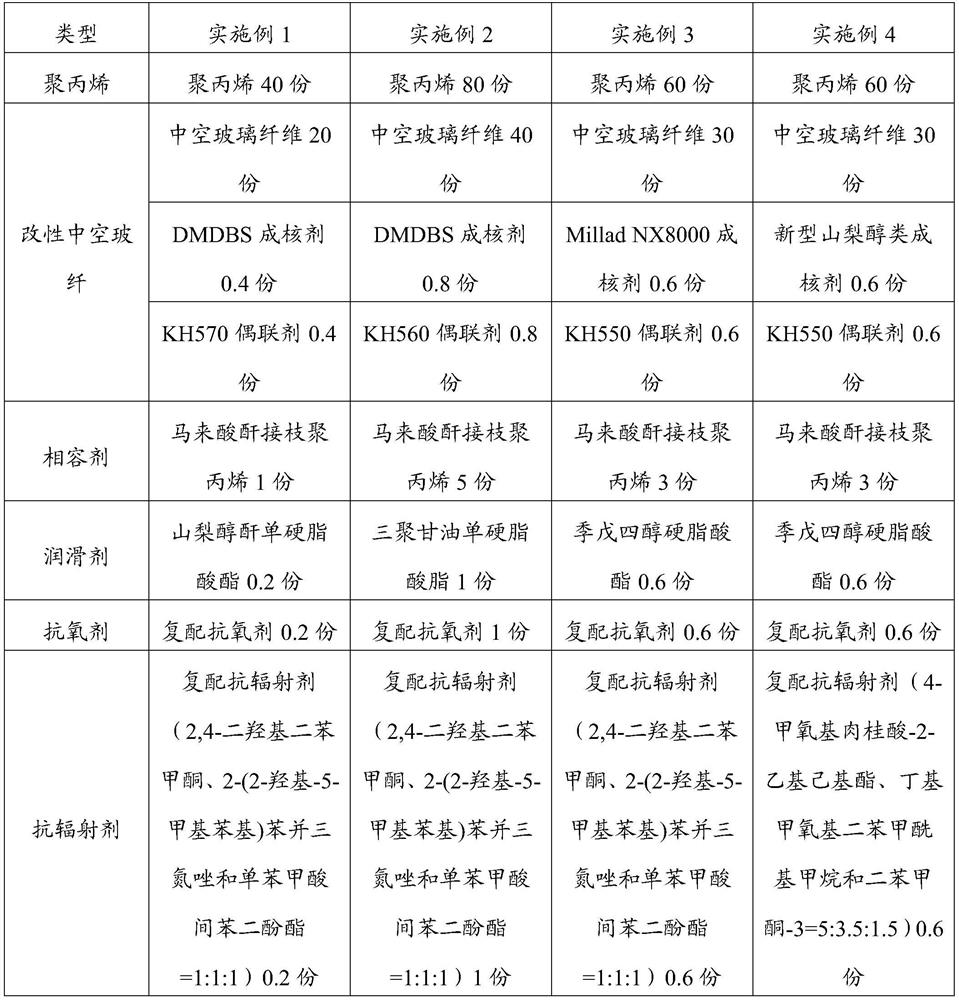

Yellowing-resistant aqueous adhesive and preparation method thereof

ActiveCN110467891AGood yellowing resistanceGood high/low temperature resistanceNon-macromolecular adhesive additivesMacromolecular adhesive additivesAntioxidantAdhesive

The invention discloses a yellowing-resistant aqueous adhesive and a preparation method thereof, wherein the yellowing-resistant aqueous adhesive is prepared from the following raw materials by weight: 38-48 parts of polyvinyl alcohol, 23-29 parts of aqueous polyvinyl formal, 28-35 parts of an aqueous ethylene-vinyl acetate copolymer, 12-16 parts of silicone-acrylic emulsion, 2-4 parts of an emulsifier, 3-6 parts of an ultraviolet ray absorber, and 2.5-4 parts of an antioxidant, wherein the ultraviolet ray absorber is a mixture of 2-(2'-hydroxy-5'-methylphenyl)benzotriazole and resorcinol monobenzoate. According to the present invention, by selecting the raw materials and optimizing the ratio of the raw materials, the advantages of various raw materials are completely provided, and complement and promote each other, and the prepared yellowing-resistant aqueous adhesive has advantages of good yellowing resistance, good high / low temperature resistance and high 180 DEG peel strength.

Owner:福建省统一环保科技有限公司

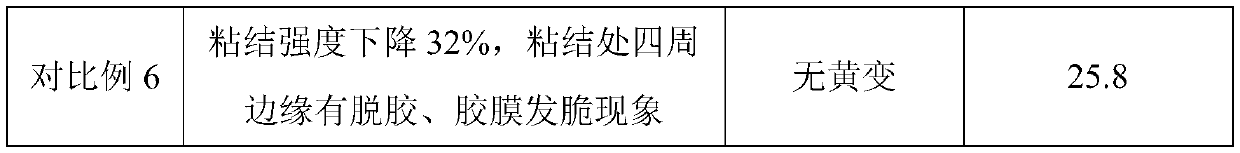

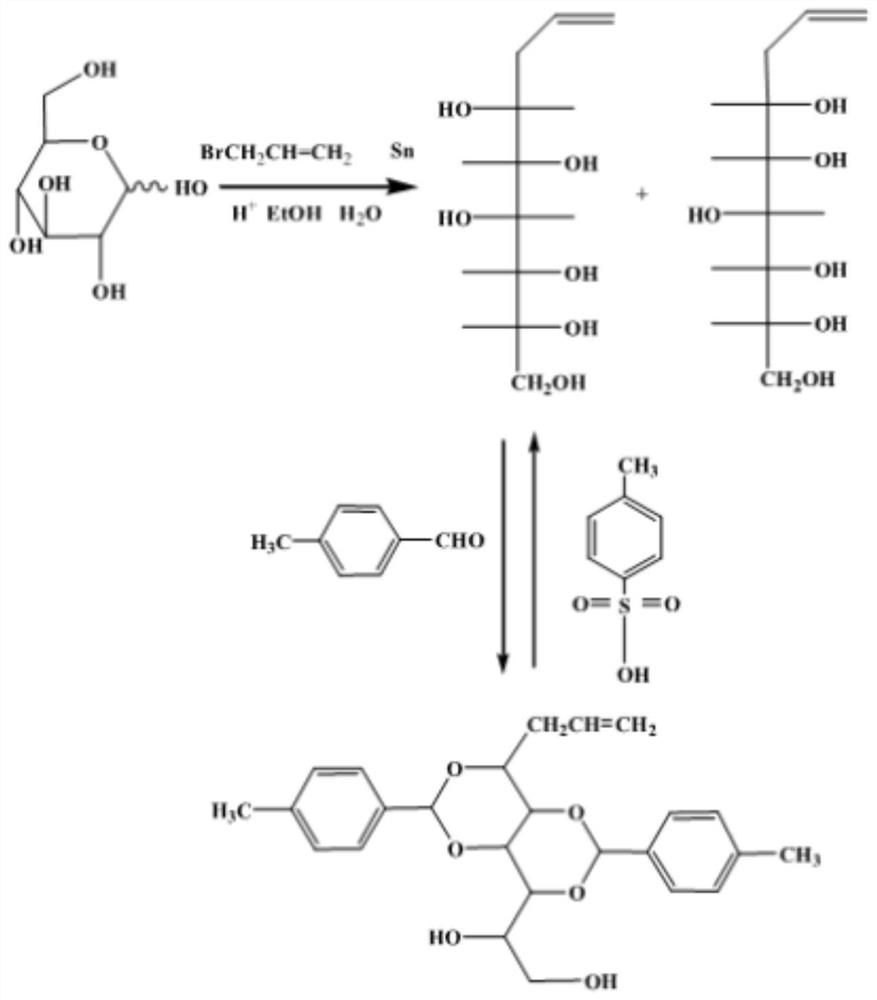

A special tape used on protective clothing

ActiveCN112852314BEvenly distributedEvenly distributed and firmPressure sensitive film/foil adhesivesBenzoic acidPolymer science

The invention relates to the technical field of medical tapes, and discloses a special tape for protective clothing, comprising a polypropylene base film layer and a pressure-sensitive adhesive layer, and the pressure-sensitive adhesive layer is adhered to one side of the polypropylene base film layer; The polypropylene base film layer is made of polypropylene composite material, and the polypropylene composite material, in parts by weight, includes the following components: 40-80 parts of polypropylene, 20-40 parts of modified hollow glass fiber, and 1 compatibilizer ~5 parts, 0.2-1 part of lubricant, 0.2-1 part of antioxidant, and 0.2-1 part of anti-radiation agent; wherein, anti-radiation agent comprises butylmethoxydibenzoylmethane, 4-methoxycinnamic acid- 2-ethylhexyl ester, 2-hydroxy-4-n-octyloxybenzophenone, 2,4-dihydroxybenzophenone, resorcinol monobenzoate, 2-(2-hydroxy-5 -methylphenyl) at least one of benzotriazole and benzophenone-3. This special tape has excellent radiation resistance, heat resistance and transparency.

Owner:HUIZHOU HAOMING SCI & TECH

Polyisobutylene lubricant

PendingCN113372982AImprove thermal stabilityImprove high temperature resistanceLubricant compositionOXALIC ACID DIHYDRATEPolymer science

The invention belongs to the field of lubricants, particularly relates to a polyisobutene lubricant, and provides the following scheme aiming at the problem of poor temperature resistance of existing lubricating oil. The high-temperature-resistant insulating material is prepared from the following raw materials in parts by weight: 40 to 50 parts of polyisobutene, 5 to 10 parts of graphite powder, 10 to 15 parts of silicone oil, 1 to 5 parts of polyvinyl alcohol, 0.5 to 1 part of oxalic acid diester, 0.5 to 1 part of di-iso-decyl phthalate, 0.1 to 0.5 part of vinyl ester resin, 0.5 to 1 part of octadecyl thiodipropionate, 0.1 to 0.5 part of calcium glycerophosphate, 1 to 5 parts of calcium stearate, 0.3 to 0.7 part of polyimide, 0.4 to 0.8 part of N-phenylmaleimide, 0.1 to 0.5 part of 2-hydroxy-4-methoxybenzophenone, 0.5 to 1 part of distearyl thiodipropionate and 0.1 to 0.5 part of resorcinol monobenzoate. According to the present invention, the polyisobutylene lubricant has advantages of excellent temperature resistance and simple preparation method.

Owner:GUANGDONG ALLPASS LUBRICATION TECH

Improved flame-retardant plastic additive

The present invention relates to an improved flame-retardant plastic additive comprising, in parts by weight, 42-55 parts of antimonous oxide, 36-40 parts of zinc borate, 24-29 parts of tetrabromobutane, 15-18 parts of phosphotriester, 6-14 parts of epichlorohydrin, 3-8 parts of barium stearate, and 2-5 parts of resorcinol monobenzoate. The improved flame-retardant plastic additive is easy to process, high in flame retardancy and stable in performance.

Owner:宜兴市聚金信科技有限公司

High-permeability plastic formula for cosmetic plastics

The invention discloses a high-permeability plastic formula for cosmetic plastics. The plastic formula comprises, by weight, 150 parts of HDPE resin, 2-3 parts of an antioxidant, 3-5 parts of a plastic brightener, 0.4-0.5 parts of an ultraviolet absorber, 2-3 parts of an antistatic agent and 4-6 parts of a flexibilizer. The ultraviolet absorber is prepared by mixing phenyl salicylate and resorcinol monobenzoate according to a ratio of 1: 1. The plastic has the characteristics of good light transmission, good toughness, no toxicity and the like.

Owner:杭州迅美塑料制品有限责任公司

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com