Epoxy encapsulation adhesive for high power LED encapsulation and preparation method for epoxy encapsulation adhesive and use of epoxy encapsulation adhesive

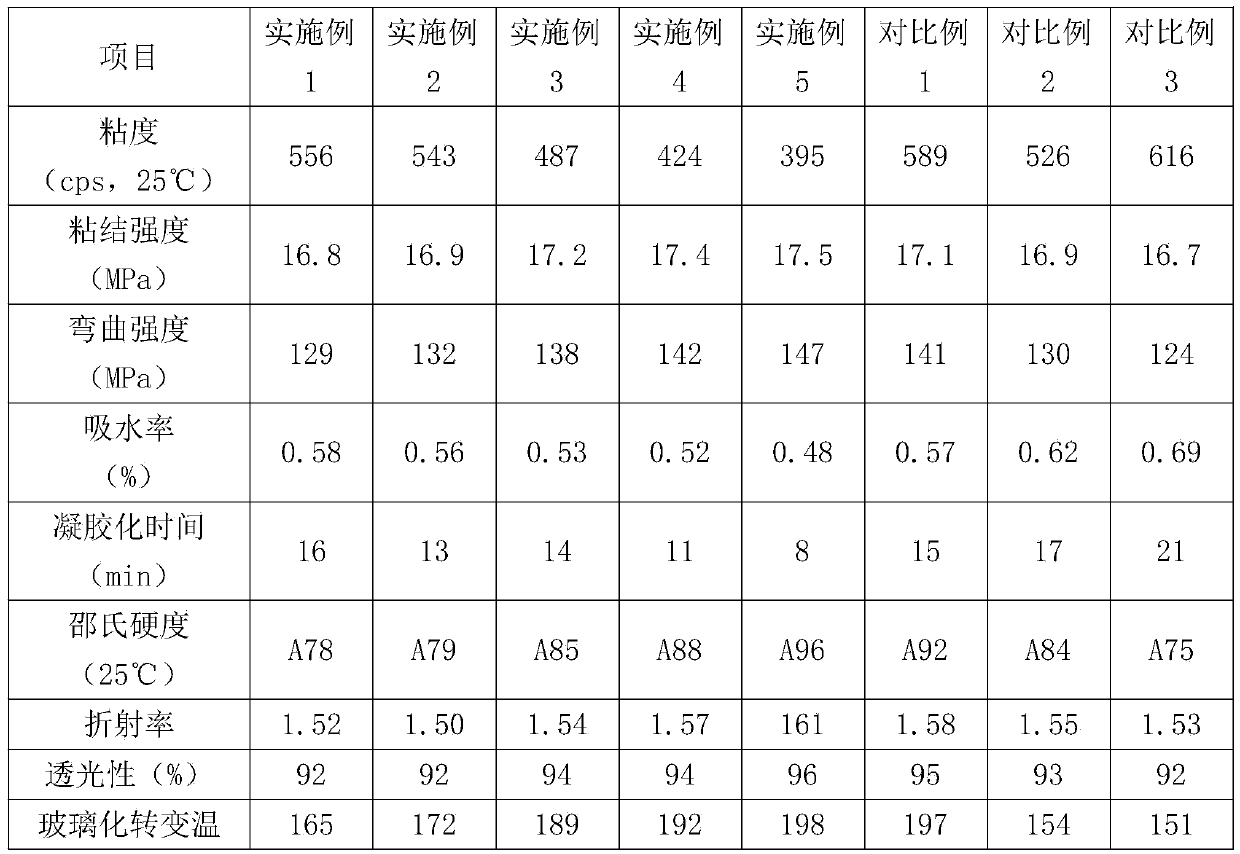

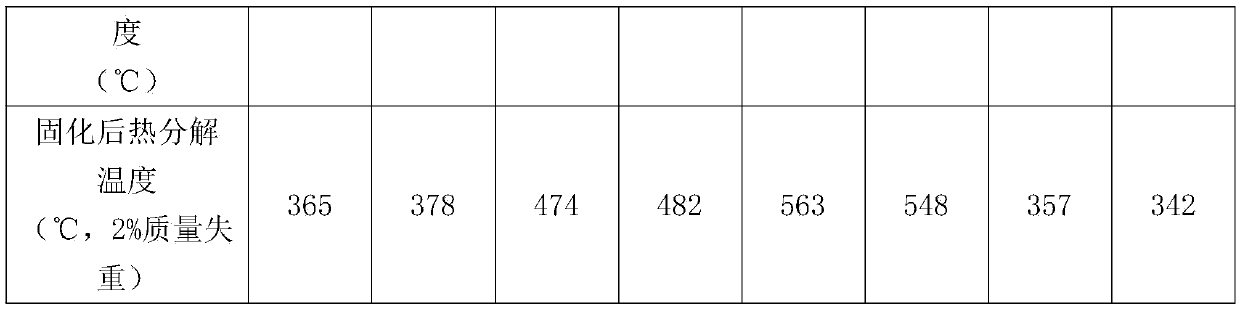

A technology of LED encapsulation and epoxy resin, applied in the direction of epoxy resin glue, adhesive, polymer adhesive additives, etc., can solve the problems of high price of silicone resin, urgent packaging materials, small output, etc., to achieve low cost, The effect of high glass transition temperature and thermal decomposition temperature and strong bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] In the embodiment of the present invention, the epoxy resin encapsulant for high-power LED encapsulation is a two-component system, consisting of 47% of component A and 53% of component B in terms of mass percentage; In percentage terms, it is made of 19.85% of bisphenol F epoxy resin, 80% of phenolic modified silicone resin and 0.15% of polyether modified polysiloxane. The B component is made of Korean pine Made from 14% extract, 85% adipic dihydrazide, 0.4% resorcinol monobenzoate and 0.6% 4-benzoyloxy-2,2,6,6-tetramethylpiperidine The preparation method of described Korean pine extract, comprises the following steps:

[0025] 1) Wash the roots or stems of the Korean pine, pulverize them, and pass through a 40-mesh sieve to obtain coarse powder;

[0026] 2) Adding 5 times the volume concentration of the coarse powder to the coarse powder is an 88% ethanol solution, soaked for 12 hours, then heated to boiling and refluxed for 3 hours, filtered, and slowed down by perc...

Embodiment 2

[0034] In the embodiment of the present invention, the epoxy resin encapsulant for high-power LED encapsulation is a two-component system, consisting of 42% of A component and 58% of B component in terms of mass percentage; In percentage terms, it is made of 80% of bisphenol F epoxy resin, 19.85% of phenolic modified silicone resin and 0.15% of polyether modified polysiloxane. The B component is made of Korean pine Made from 27% extract, 72% adipate dihydrazide, 0.4% resorcinol monobenzoate and 0.6% 4-benzoyloxy-2,2,6,6-tetramethylpiperidine The preparation method of described Korean pine extract, comprises the following steps:

[0035] 1) Wash the roots or stems of the Korean pine, pulverize them, and pass through a 40-mesh sieve to obtain coarse powder;

[0036] 2) Adding 5 times the volume concentration of the coarse powder to the coarse powder is an 88% ethanol solution, soaked for 12 hours, then heated to boiling and refluxed for 3 hours, filtered, and slowed down by per...

Embodiment 3

[0044] In the embodiment of the present invention, the epoxy resin encapsulant for high-power LED encapsulation is a two-component system, consisting of 43.8% of component A and 56.2% of component B in terms of mass percentage; In percentage terms, it is made of 45% of bisphenol F epoxy resin, 54.75% of phenolic modified silicone resin and 0.25% of polyether modified polysiloxane. The B component is made of Korean pine Made from 20% extract, 78% adipate dihydrazide, 1.0% resorcinol monobenzoate and 1.0% 4-benzoyloxy-2,2,6,6-tetramethylpiperidine The preparation method of described Korean pine extract, comprises the following steps:

[0045] 1) Wash the roots or stems of Korean pine, grind them, and pass through an 80-mesh sieve to obtain coarse powder;

[0046] 2) Add 6 times the mass of the coarse powder to the coarse powder in an ethanol solution with a volume concentration of 75%, soak for 18 hours, then heat to boiling and reflux for 5 hours, filter, and slowly use the pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com