Polyisobutylene lubricant

A polyisobutylene lubricant, polyisobutylene technology, applied in lubricating compositions, petroleum industry, etc., can solve problems such as poor temperature resistance of lubricating oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

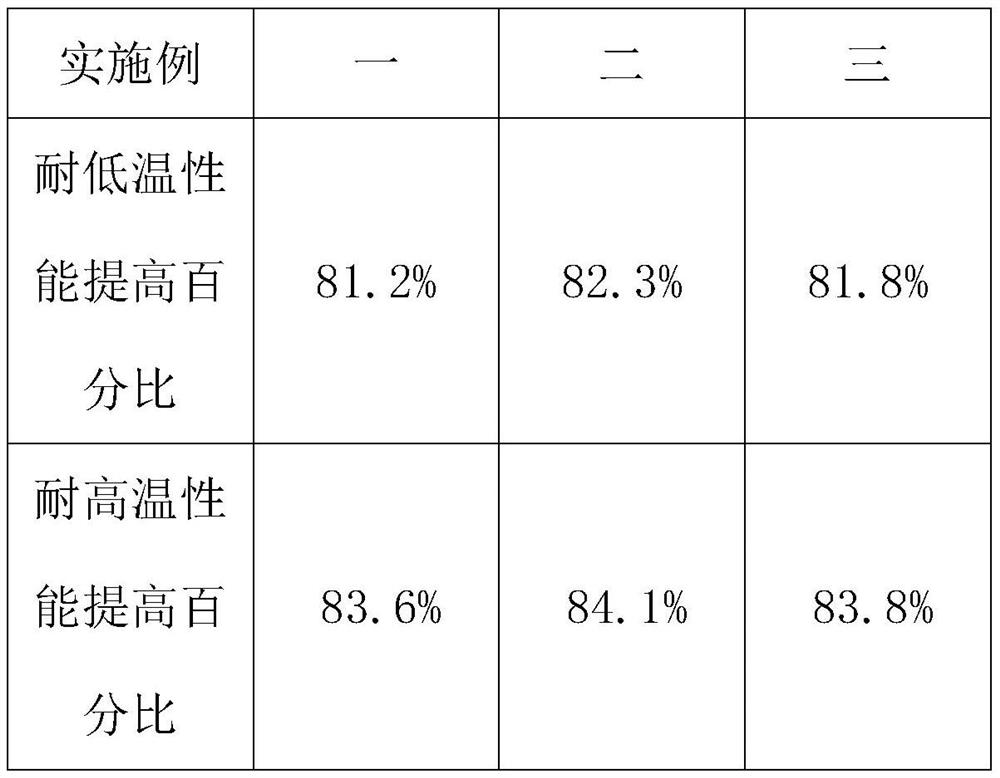

Examples

Embodiment 1

[0026] The present invention proposes a polyisobutylene lubricant, comprising the following raw materials in parts by weight: 40 parts of polyisobutylene, 5 parts of graphite powder, 10 parts of silicone oil, 1 part of polyvinyl alcohol, 0.5 parts of oxalic acid diester, phthalic acid 0.5 part of diisodecyl, 0.1 part of vinyl ester resin, 0.5 part of stearyl thiodipropionate, 0.1 part of calcium glycerophosphate, 1 part of calcium stearate, 0.3 part of polyimide, N-phenyl maleic acid 0.4 part of imide, 0.1 part of 2-hydroxy-4-methoxybenzophenone, 0.5 part of distearyl thiodipropionate, 0.1 part of resorcinol monobenzoate;

[0027] Its preparation method comprises the following steps:

[0028] S1: First put polyisobutylene, graphite powder, silicone oil, and polyvinyl alcohol into the mixing equipment, stir and mix, the mixing time is 10 minutes, and the mixing speed is 200r / min to prepare the mixture A;

[0029] S2: Add oxalic acid diester, diisodecyl phthalate, and vinyl est...

Embodiment 2

[0033] The present invention proposes a polyisobutylene lubricant, comprising the following raw materials in parts by weight: 45 parts of polyisobutylene, 7 parts of graphite powder, 12 parts of silicone oil, 3 parts of polyvinyl alcohol, 0.7 parts of oxalic acid diester, phthalic acid 0.8 parts of diisodecyl, 0.3 parts of vinyl ester resin, 0.7 parts of stearyl thiodipropionate, 0.3 parts of calcium glycerophosphate, 3 parts of calcium stearate, 0.5 parts of polyimide, N-phenyl maleic acid 0.6 part of imide, 0.3 part of 2-hydroxy-4-methoxybenzophenone, 0.7 part of distearyl thiodipropionate, 0.3 part of resorcinol monobenzoate;

[0034] Its preparation method comprises the following steps:

[0035] S1: First put polyisobutylene, graphite powder, silicone oil, and polyvinyl alcohol into the mixing equipment, stir and mix, the mixing time is 15 minutes, and the mixing speed is 250r / min to prepare the mixture A;

[0036] S2: Add oxalic acid diester, diisodecyl phthalate, and vi...

Embodiment 3

[0040]The present invention proposes a polyisobutylene lubricant, comprising the following raw materials in parts by weight: 50 parts of polyisobutylene, 10 parts of graphite powder, 15 parts of silicone oil, 5 parts of polyvinyl alcohol, 1 part of oxalic acid diester, phthalic acid 1 part of diisodecyl, 0.5 parts of vinyl ester resin, 1 part of stearyl thiodipropionate, 0.5 parts of calcium glycerophosphate, 5 parts of calcium stearate, 0.7 parts of polyimide, N-phenyl maleic acid 0.8 part of imide, 0.5 part of 2-hydroxy-4-methoxybenzophenone, 1 part of distearyl thiodipropionate, 0.5 part of resorcinol monobenzoate;

[0041] Its preparation method comprises the following steps:

[0042] S1: First put polyisobutylene, graphite powder, silicone oil, and polyvinyl alcohol into the mixing equipment, stir and mix, the mixing time is 20min, and the mixing speed is 300r / min to prepare the mixture A;

[0043] S2: Add oxalic acid diester, diisodecyl phthalate, and vinyl ester resin ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com